Organization

Coordinator and Local Coordinator Chemnitz:

Prof.-Dr.-Ing. Welf-Guntram Drossel

Representative Coordinator:

Prof. Dr.-Ing. habil. Carolin Körner

Regional Coordinator Dresden:

Prof. Dr.-Ing. Niels Modler

Regional Coordinator Erlangen:

Prof. Dr.-Ing. habil. Carolin Körner

Manufacturing technologies of the automobile engineering were chosen as an example for a widespread application. Each region masterminds one process chain. Chemnitz is responsible for the process chain of sheet metal forming, Dresden for the production of structural components from fiber composites and Erlangen for casting piezoceramic fiber and sheet modules into innovative lightweight materials through pressure casting.

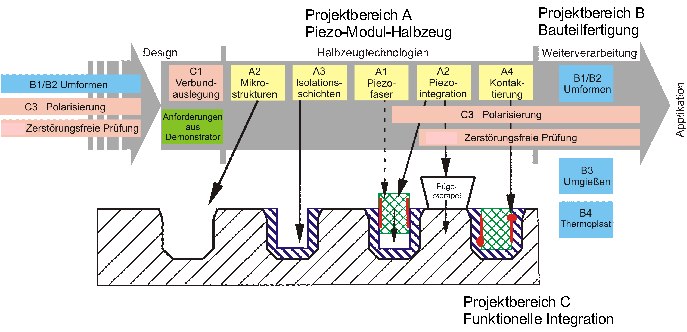

The works of the transregio are coordinated in three project areas (A-C), whereas area A combines all projects that prepare corresponding modules from piezoceramics for a subsequent processing with the component manufacturing technologies. Area B comprises all projects directly examining the technologies of the component manufacturing. The overall objective of area C is the functional integration in which especially questions on design, simulation of the component behavior, polarisation (activation of the integrated piezoceramics) and on the setting of defined mechanical contact ratio in the limiting layer are explored.

The collaboration and the results of the project areas and single projects are clarified in the following illustration by means of the process chain of forming of aluminum sheet metal with integrated piezo modules.