Simulation of Curing and Shrinking Processes of Joining Materials in malleable Piezo-Metal-Compounds

J. Ihlemann

Aims

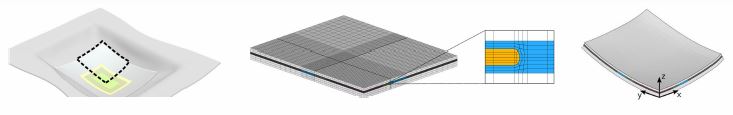

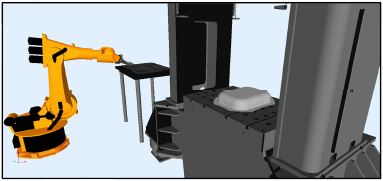

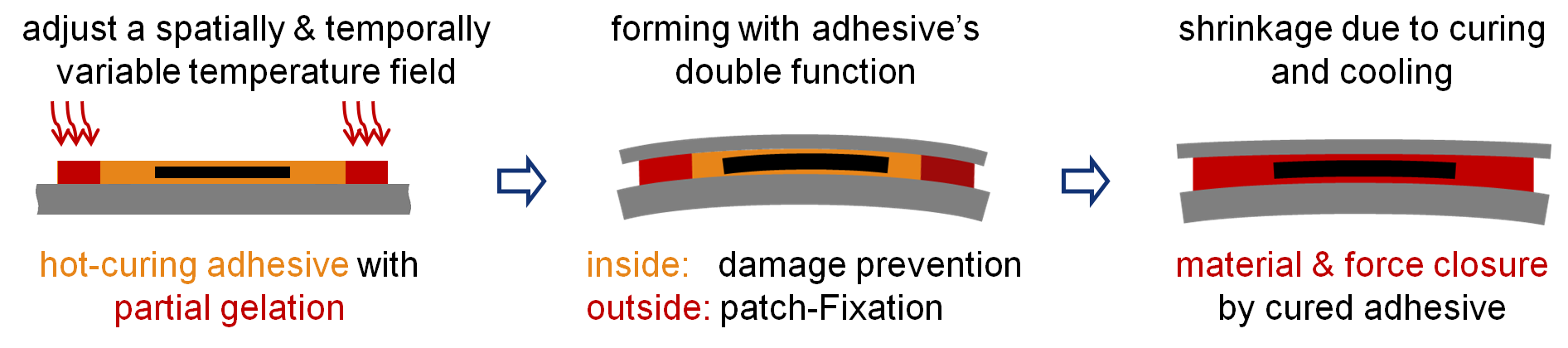

Process chain Forming

|

|

Conceptual approach of the process chain Forming

|

Subproject C07

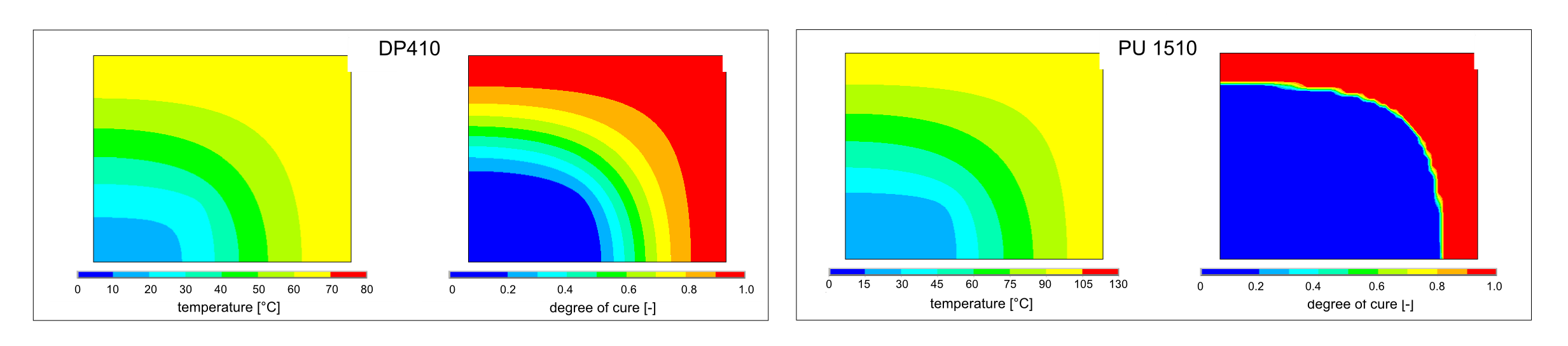

- Simulation of gelation and curing

- Integrated implementation of the simulation concept in cooperation with subproject B01

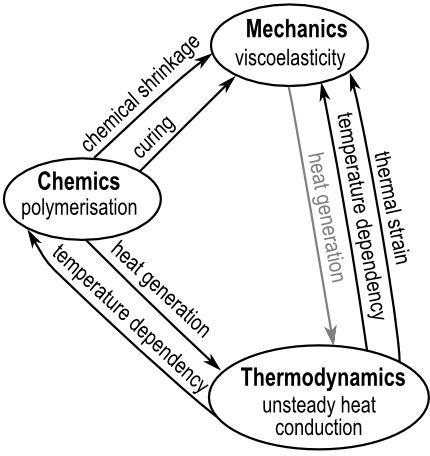

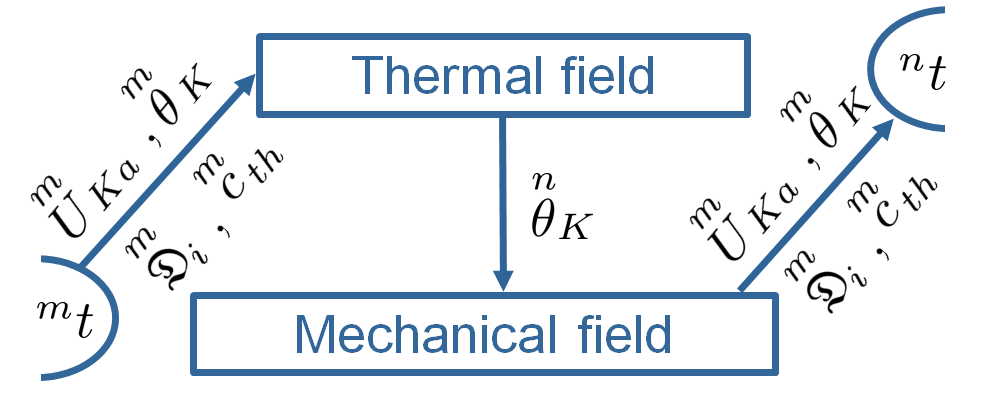

- Fully coupled thermo-mechanical-chemical simulation

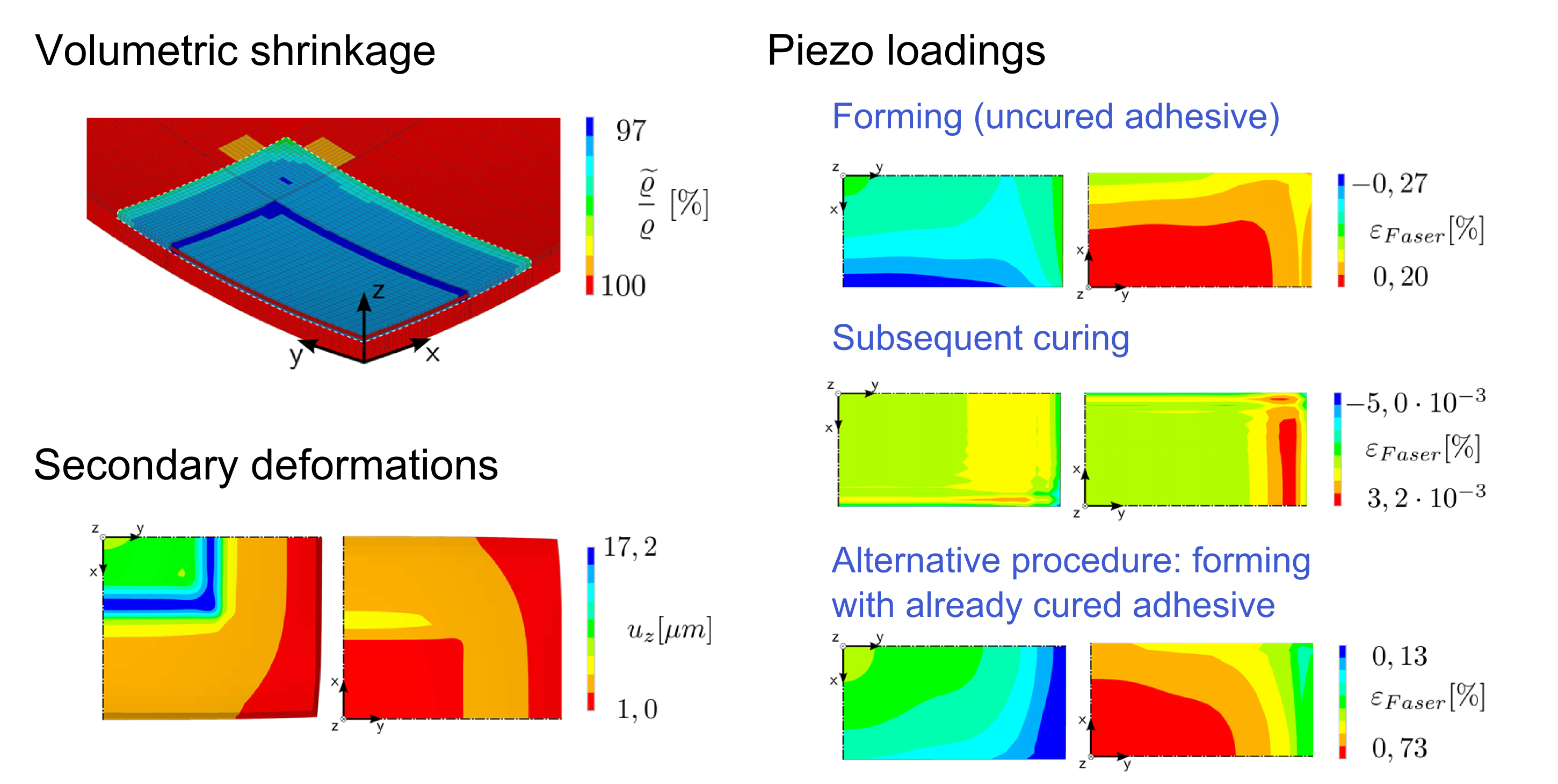

- Calculation of residual stresses, secondary deformations and piezo loading

- Prediction of process windows by systematic parameter variations

- Investigation of optimal production processes

Results

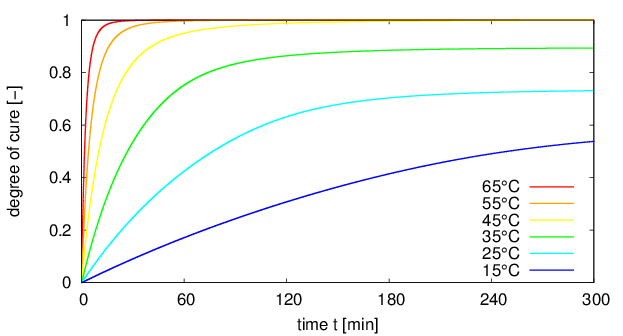

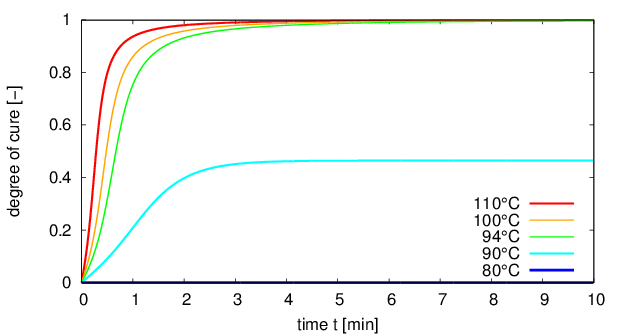

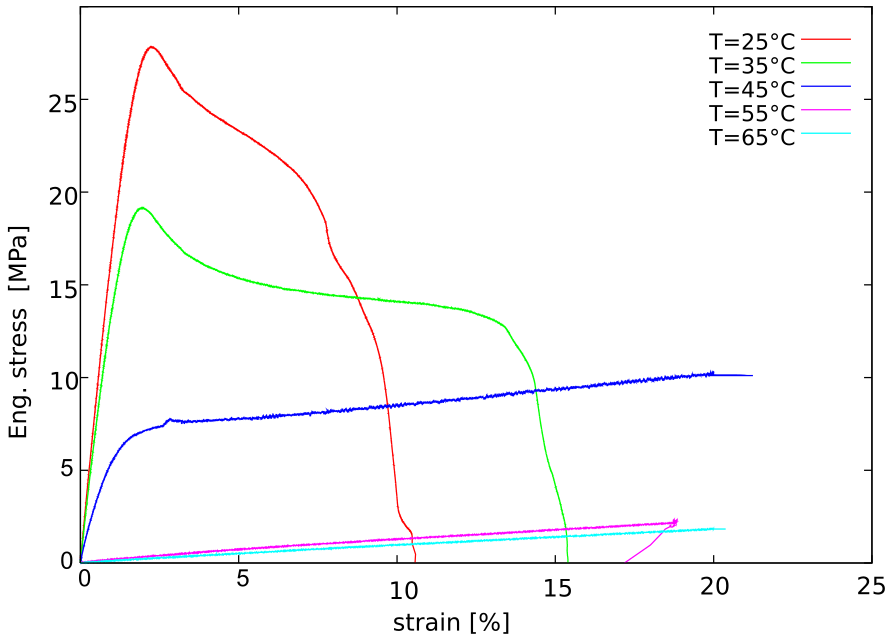

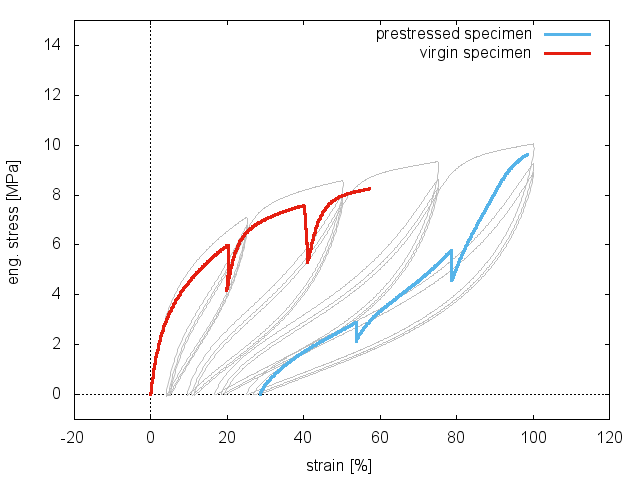

Experimental characterization and phenomenological material modelling

|

Curing reaction and degree of cure: Differential Scanning Calorimetry (DSC) |

||||

|---|---|---|---|---|

|

|

Mechanical properties |

||||

|---|---|---|---|---|

|

|

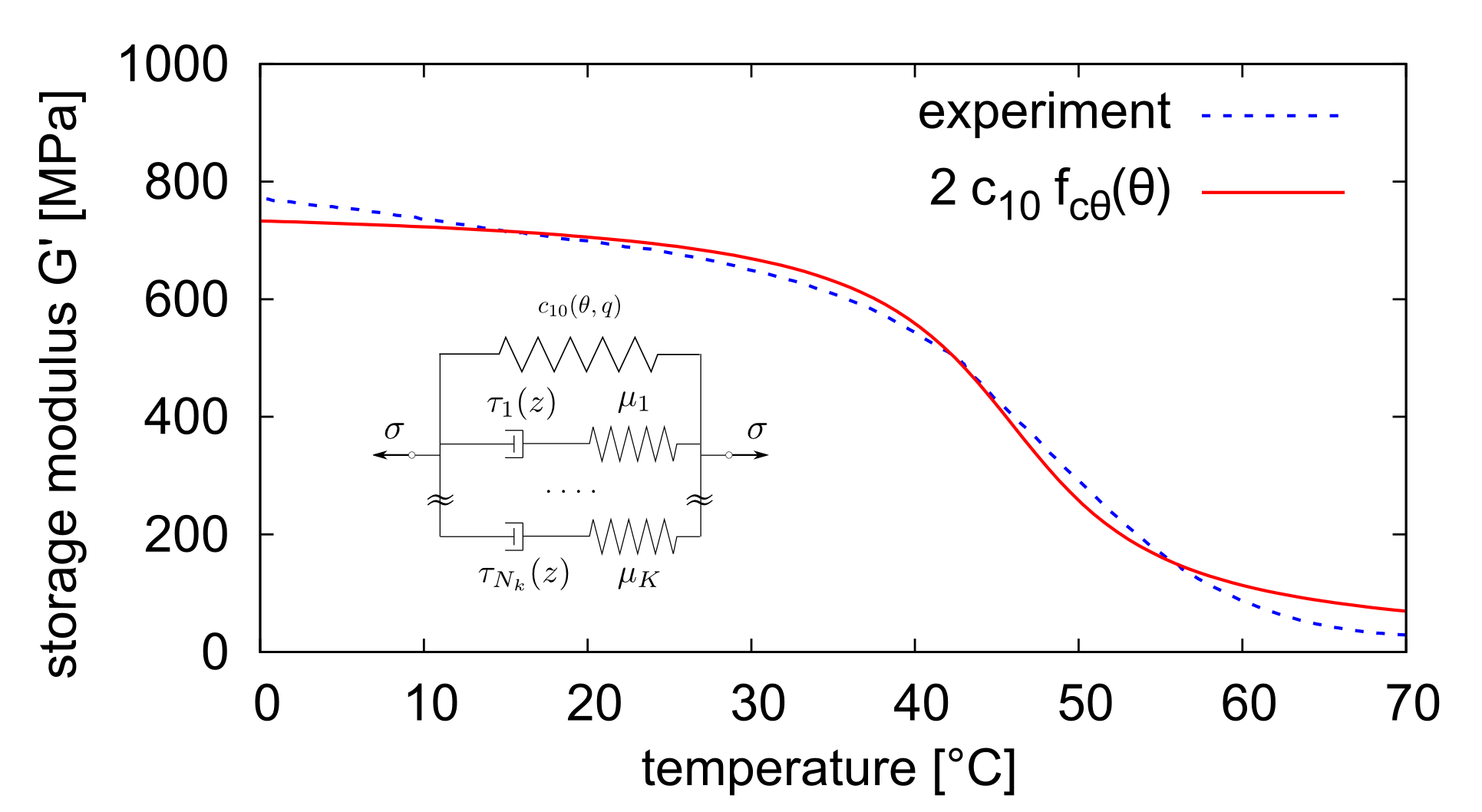

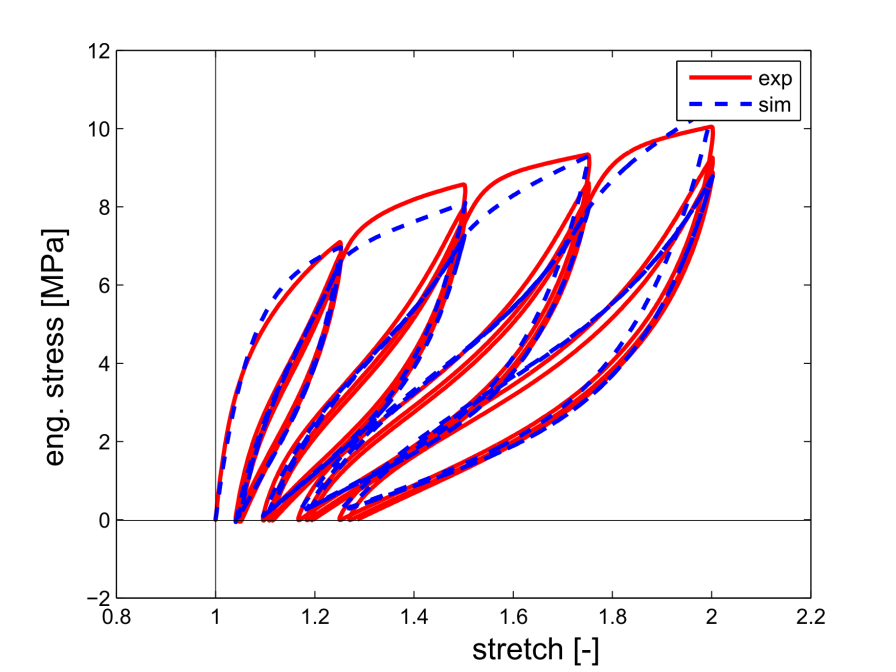

Thermomechanically coupled material model |

||||

|---|---|---|---|---|

|

|

Finite element modelling |

||||

|---|---|---|---|---|

|

Methods

|

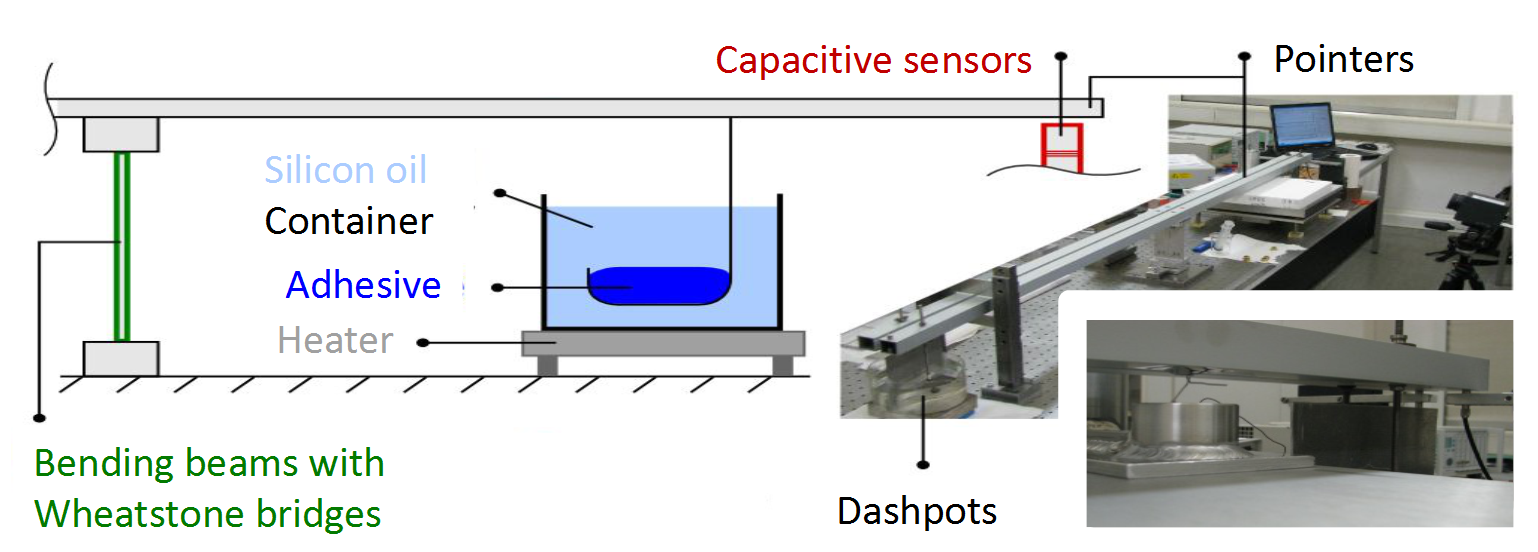

Material characterization |

|

|---|---|

|

|

Material modelling and parameter identification |

|

|---|---|

|

Material modelling

Parameter identification

|

|

|

FEM simulation tools |

|||

|---|---|---|---|

|

|

Publications

Reviewed Publications

|

[Shu13a] |

Shutov A V, Landgraf R, Ihlemann J (2013) |

|

[Lan14] |

Landgraf R, Scherzer R, Rudolph M, Ihlemann J (2014) |

|

[Kie16] |

Kießling R, Landgraf R, Scherzer R, Ihlemann J (2016) |

|

[Rud16] |

Rudolph M, Naumann C, Stockmann M (2016) |

|

[Lan16a] |

Landgraf R (2016) |

|

[Lan17] Landgraf R, Ihlemann J (2017) |

Other Publications

|

[Neu11] |

Neugebauer R, Ihlemann J, Lachmann L, Drossel W-G, Hensel S, Nestler M, Landgraf R, Rudolph M (2011) |

||

|

[Lan11a] |

Landgraf R, Ihlemann J (2011) |

||

|

[Lan11b] |

Landgraf R, Ihlemann J, Kolmeder S, Lion A (2011) |

||

|

[Lan12] |

Landgraf R, Ihlemann J (2012) |

||

|

[Neu13] |

Neugebauer R, Ihlemann J, Lachmann L, Drossel W-G, Hensel S, Nestler M, Rudolph M (2013) |

||

|

[Shu13b] |

Shutov AV, Landgraf R, Ihlemann J (2013) |

||

|

[Rud14] |

Rudolph R, Landgraf R, Ihlemann J (2013) |

||

|

[Dro15] |

Drossel W-G, Müller R, Ihlemann J, Rudolph M, Hensel S, Nestler M (2015) |

||

|

[Lan15] |

Landgraf R, Shutov A V, Ihlemann J (2015) |

||

|

[Rud15] |

Rudolph R, Landgraf R, Ihlemann J (2015) |

||

|

[Lan16b] |

Landgraf R, Ihlemann J (2016) |

[Lan17] |

Landgraf R, Ihlemann J (2017) |

Contact

Managing Director:

Prof. Dr.-Ing. habil. Jörn Ihlemann

Chemnitz University of Technology

Fakultät für Maschinenbau

Professur Festkörpermechanik

09107 Chemnitz

Telephon: +49 371 531-36946

E-Mail: joern.ihlemann@…