Subproject A1

Manufacturing Technologies for Piezoelectric Fibers and Laminates for Interation into Lightweight Structures

Project Managers:

Prof. Dr. rer. nat. habil. Alexander MichaelisTechnische Universität Dresden

Fakultät für Maschinenwesen

Institut für Werkstoffwissenschaften

Professur für Anorganisch-Nichtmetallische Werkstoffe

01062 Dresden

Telefax: +49-(0)351 2553 7600

Dr. Sylvia Gebhardt

Fraunhofer-Institut für Keramische Technologien und Systeme IKTS

Abteilung Intelligente Materialien und Systeme

Winterbergstraße 28

01277 Dresden

Telephon: +49-(0)351 2553 7694

Telefax: +49-(0)351 2554 160

E-Mail: sylvia.gebhardt@ikts.fraunhofer.de

Scientific objective target

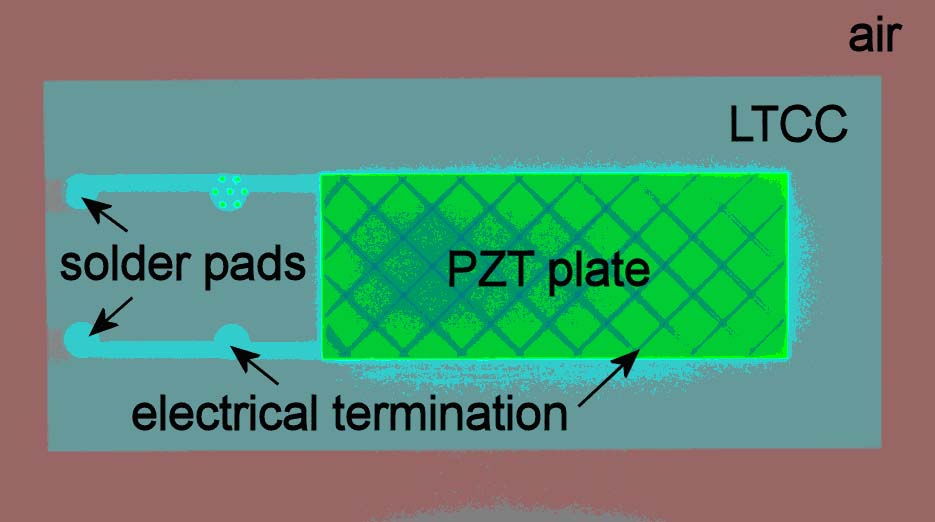

• Solution of module packaging regarding to geometry, arrangement of piezoceramic component and electrical termination allowing serial manufacturing as well as form-locking and reliable integration into lightweight structures

• Characterization and interpretation of effective material data

|

|

|

Single component |

|

|

Module | |

|

|

Structural component |

Research program

Piezoceramic fibers1. Serial production of piezoceramic fibers

2. Development of methods for single fiber characterization

3. Serial production of piezofiber composites

4. Characterization and optimization of fiber-matrix-interface

5. Adjustment of composite design to process chain demands

6. Adjustment of fiber diameter and arrangement to process chain demands

|

Piezoceramic fiber |  |

WP 1+2 |

|

Piezofiber composite |  |

WP 3+4 |

|

Piezofiber composite disc |

|

WP 5 |

|

Piezofiber composite bar | WP 6 |

Piezoceramic laminates

1. Production and characterization of LTCC/PZT modules

2. Investigation of the influence of mechanical stresses onto electromechanical properties of LTCC/PZT modules

3. Investigation and optimization of LTCC/PZT as well as LTCC/metal interface properties to achieve highest force transfer

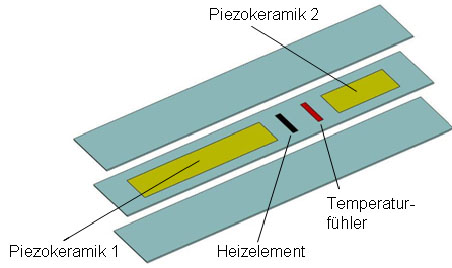

4. Integration of additional functional components into LTCC/PZT module for process control

5. Characterization of operating behavior of LTCC/PZT modules

|

LTCC/PZT module | WP 1 |

|

Integration/interfaces | WP 2+3 |

|

Augmented functionality | WP 4 |

|

Operating behavior | WP 5 |

Methods

Piezoceramic fibers• Fiber development: optimized slurry formulation, determination of spinning parameters

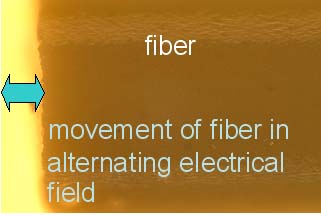

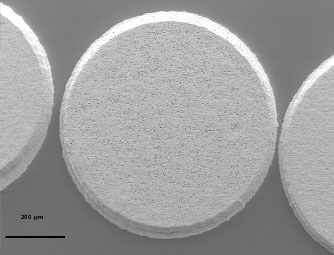

• Characterization: micro-strain-, -bend-, -pressure-methods, grayscale correlation (fig. 1)

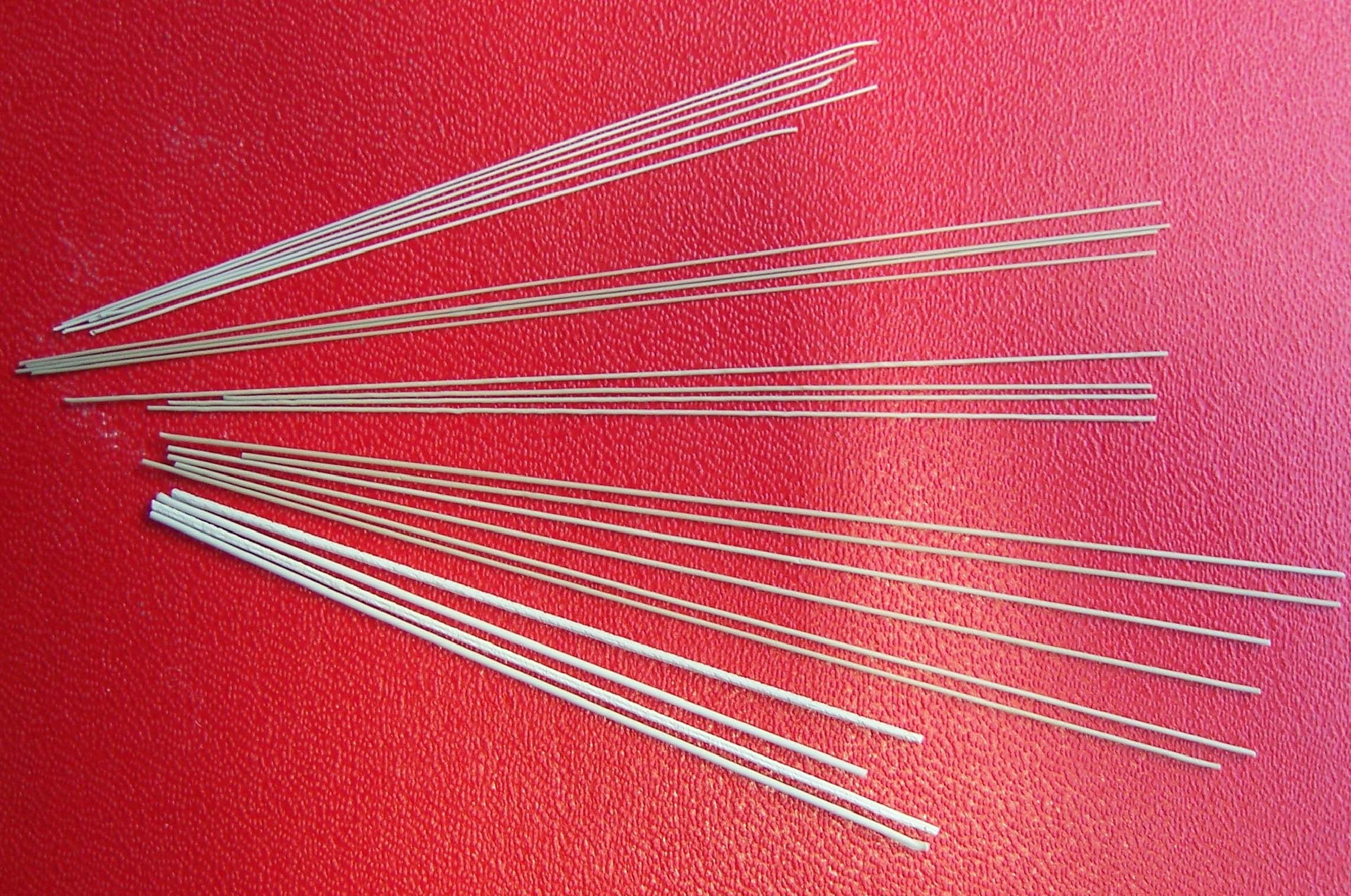

• Composite development: defined fiber arrangement, selection of matrix materials

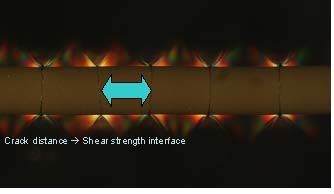

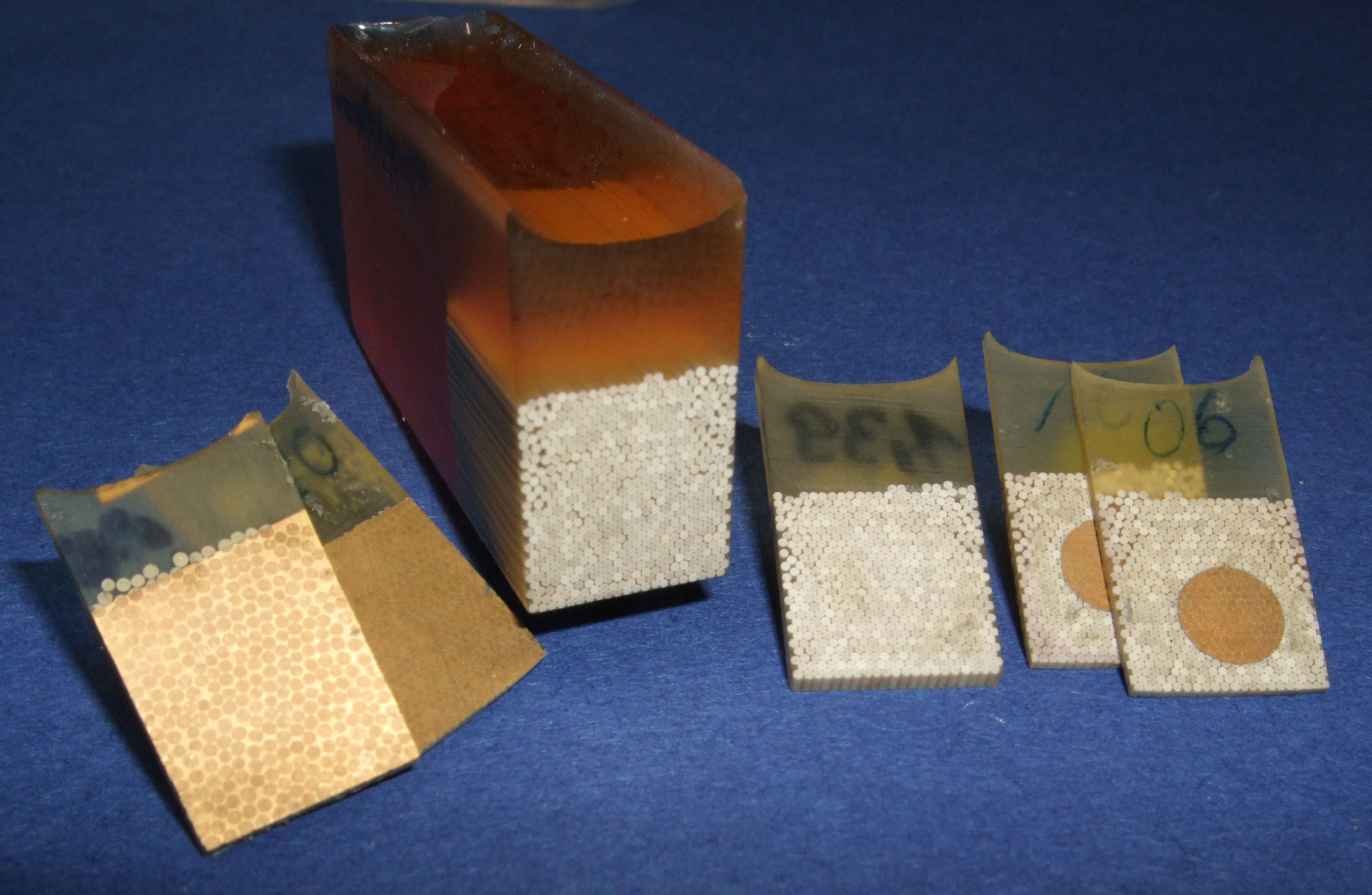

• Fiber/matrix adhesion: single fiber fragmentation test (fig. 2)

|

|

| fig. 1 | fig. 2 |

Piezoceramic laminates

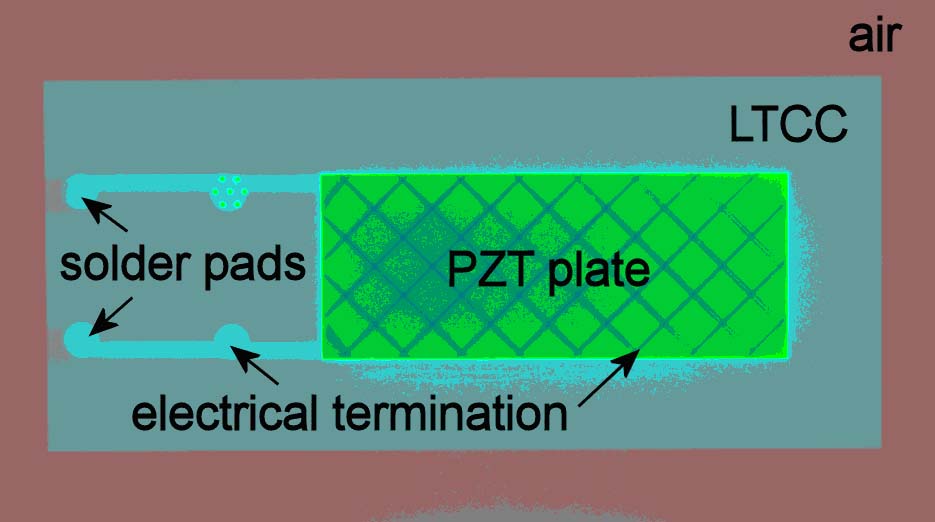

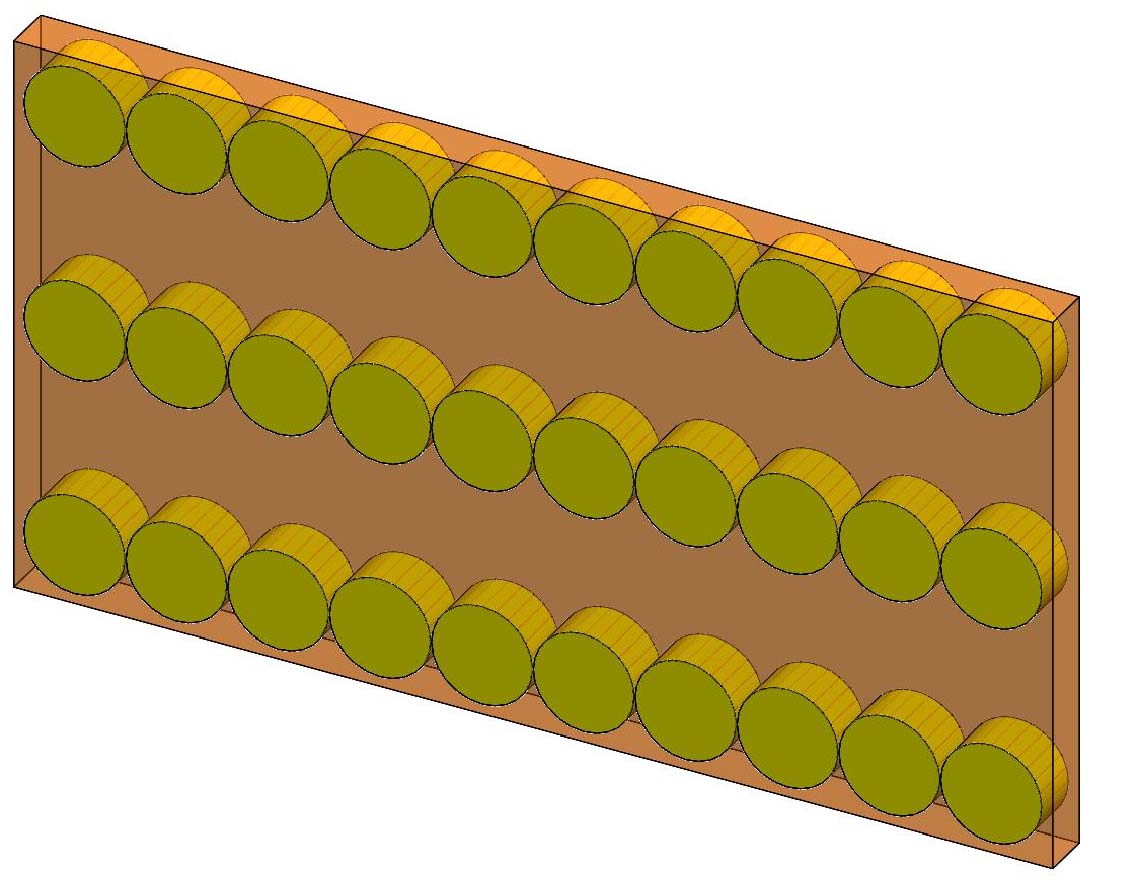

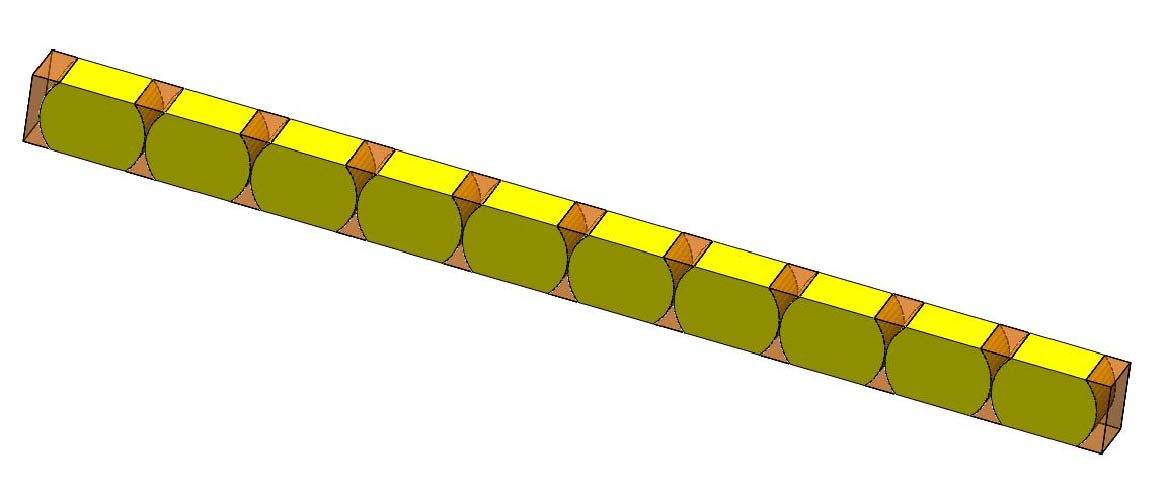

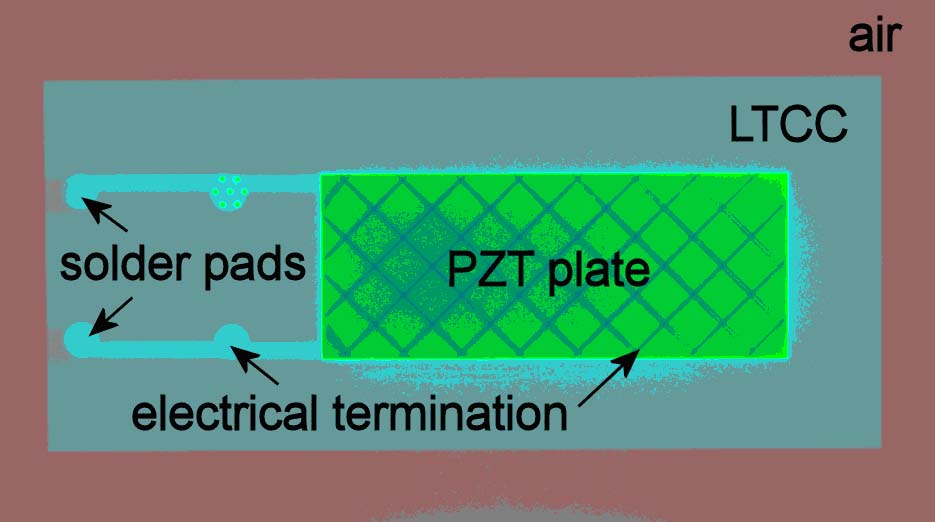

• Laminate development: optimization of packaging of integrated circuits for LTCC/PZT modules

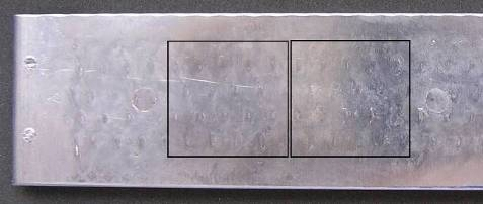

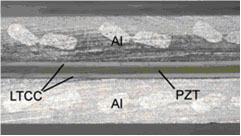

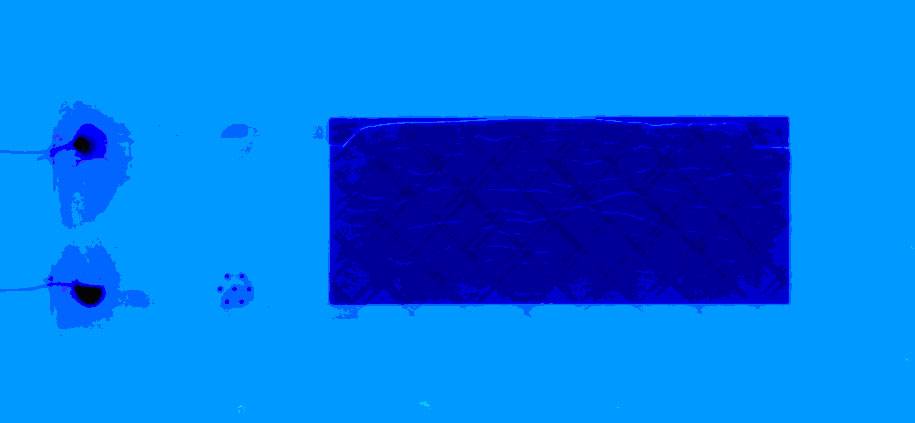

• Microstructure analysis: light-, electron beam-, ultrasound-microscopy, X-ray analysis (fig. 3)

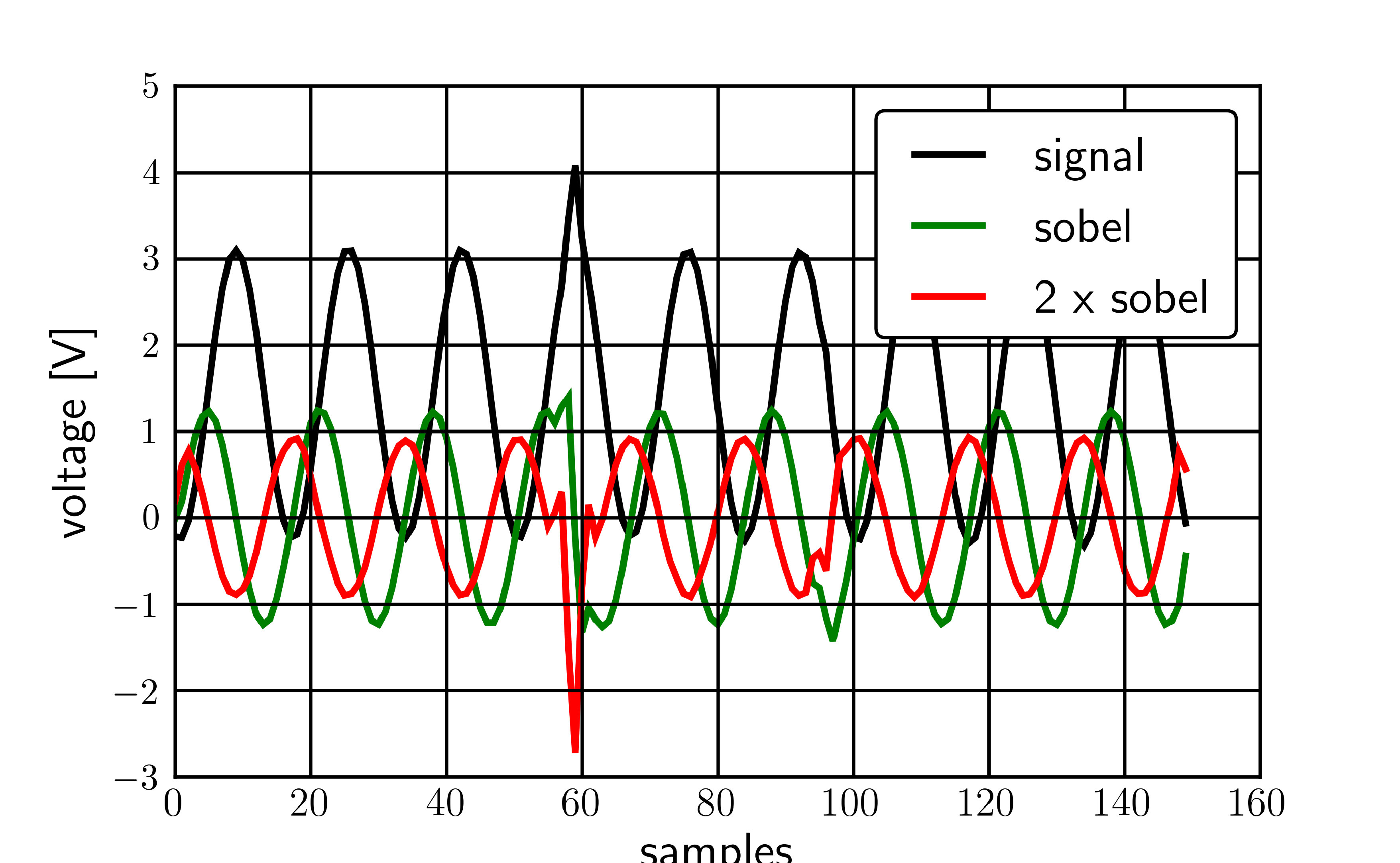

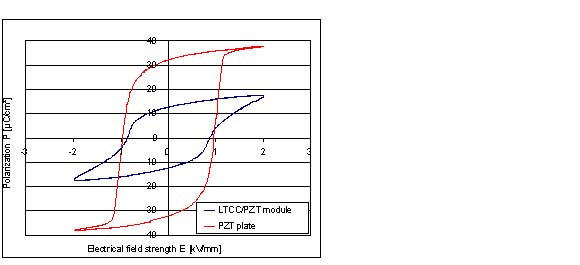

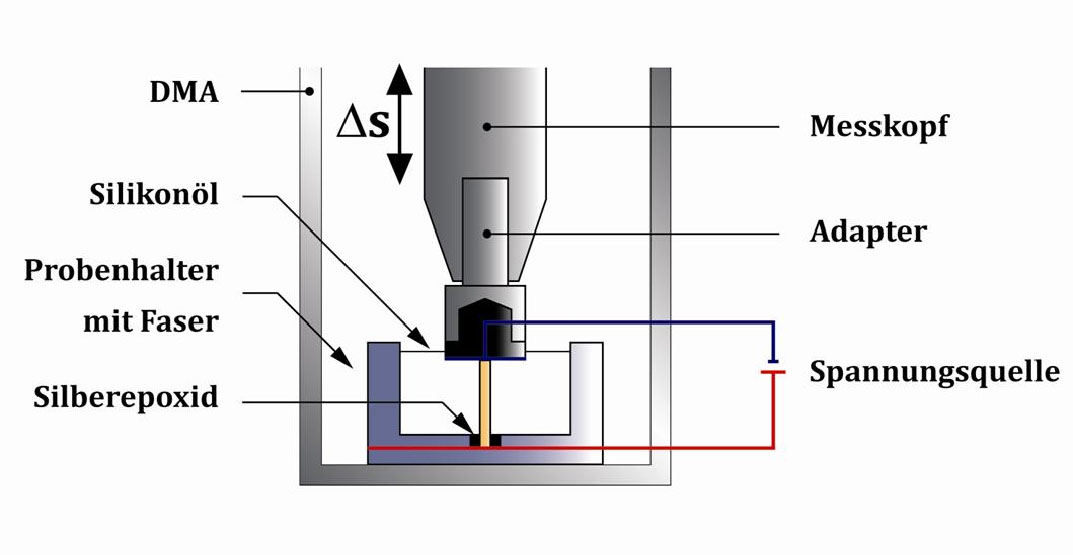

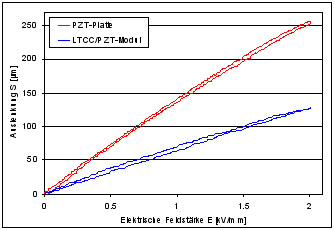

• Electromechanical characterization: measurement of electrical impedance, ferroelectric hysteresis, deflection and force (fig. 4)

• Operating behavior: electrical cycling tests

|

|

| fig. 3 |

fig. 4 |

Results in the 1st application term

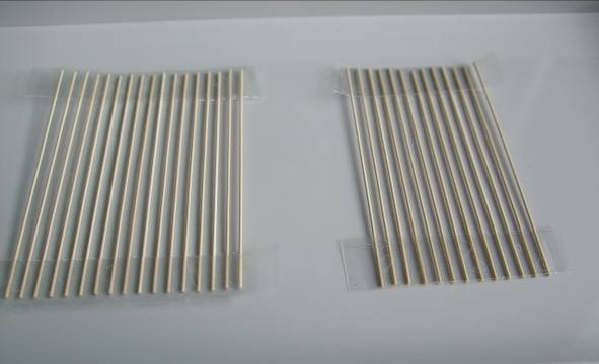

Piezoceramic fibers• Successful fabrication of piezoceramic fibers using polysulfone process:

- Free choice of the piezoceramic powder

- Porosity 3%

- Adjustment of fiber diameter: 200-1000 µm (fig. 5)

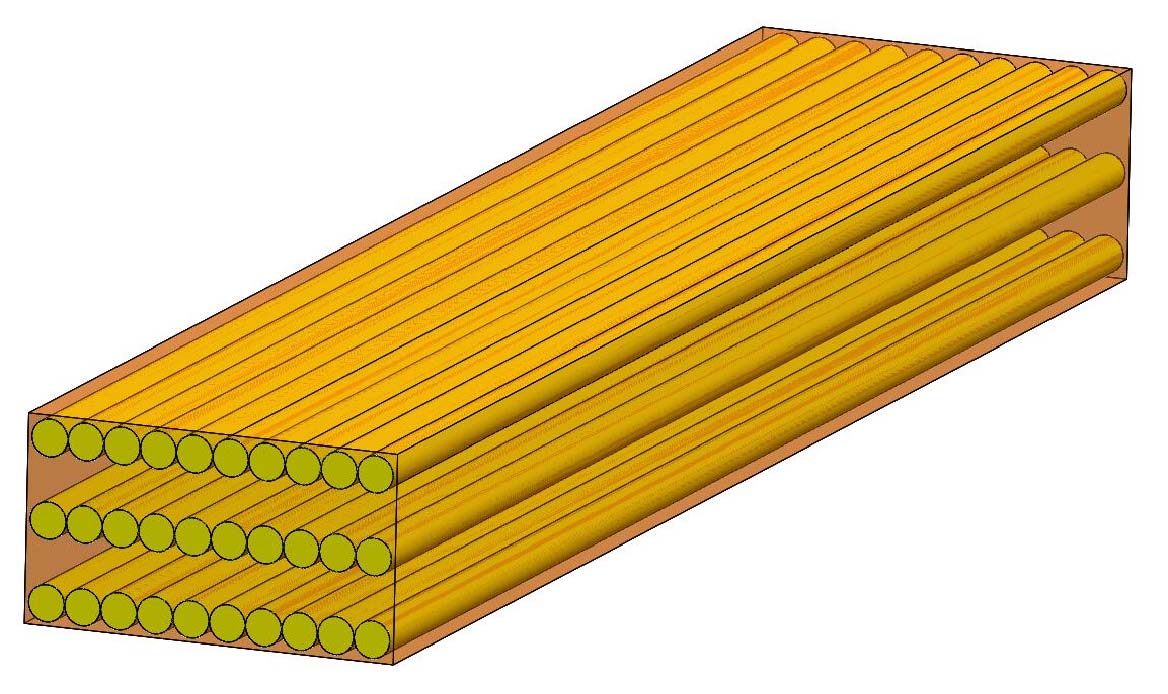

• Preparation of piezofiber composites with irregular fiber arrangement (fig. 6). Characterization of effective material data.

• Characterization of mechanical and electromechanical properties of piezoceramic fibers and comparison with state-of-the-art (fig. 7).

|

|

|

| fig. 5 | fig. 6 | fig. 7 |

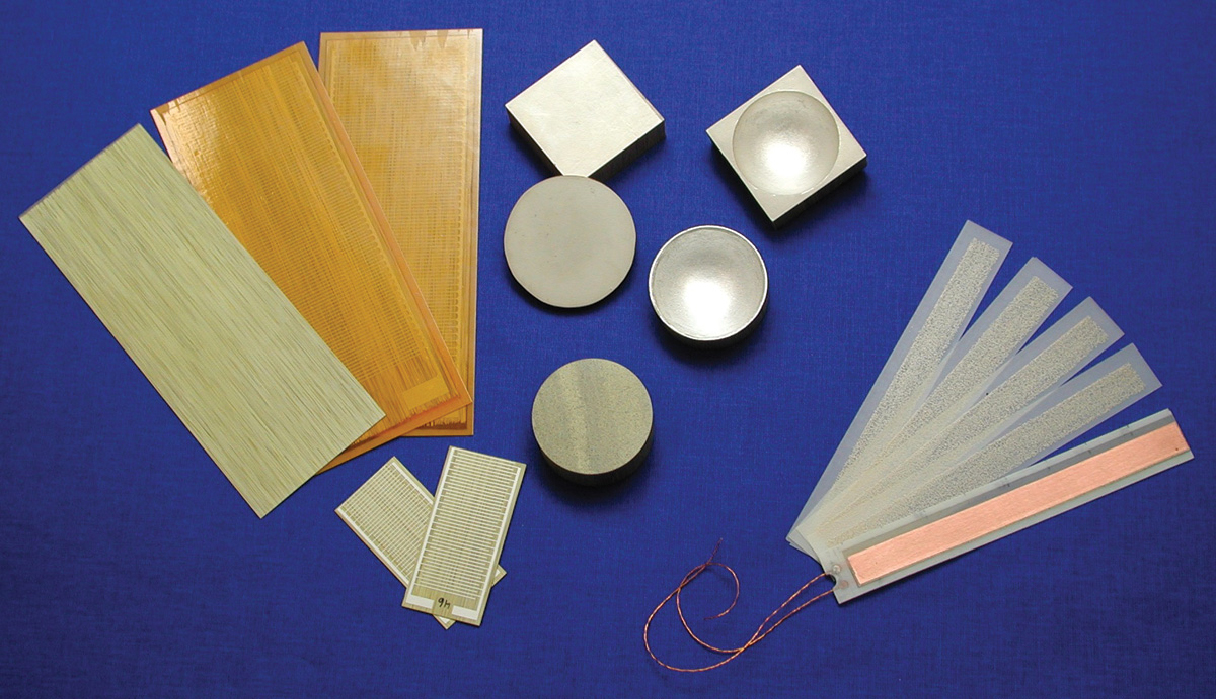

Piezoceramic laminates

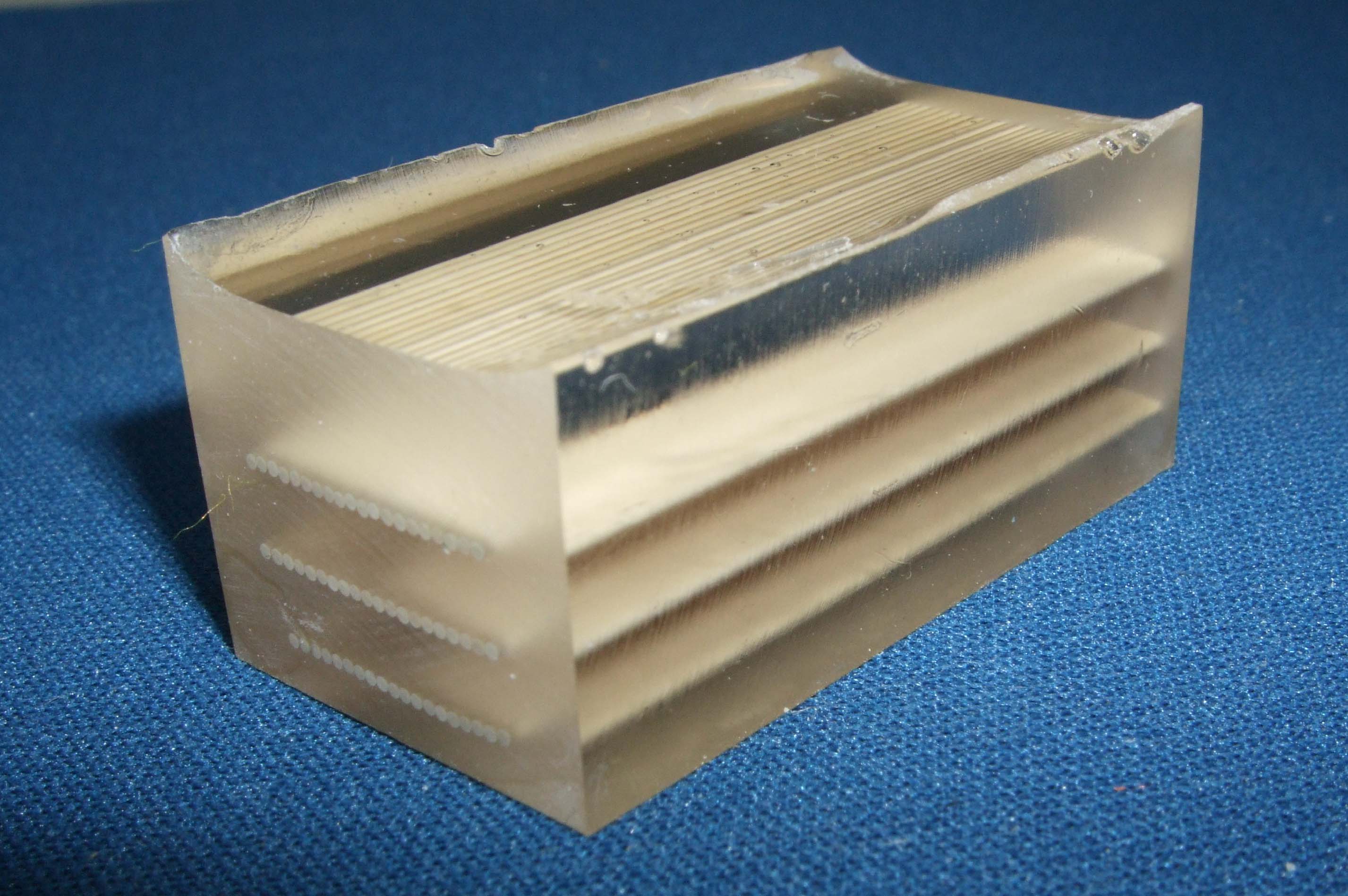

• Design and development of novel LTCC/PZT modules fully based on inorganic materials using ceramic multilayer technology (fig. 8). The following benefits could be achieved therewith:

- Mechanical stabilization and electrical termination of the piezoceramic component

- Electrical insulation to aluminum metal matrix prepared by die-casting

- Reliable interface to aluminum matrix.

• Demonstration of actuator performance using deflection measurements (fig. 9).

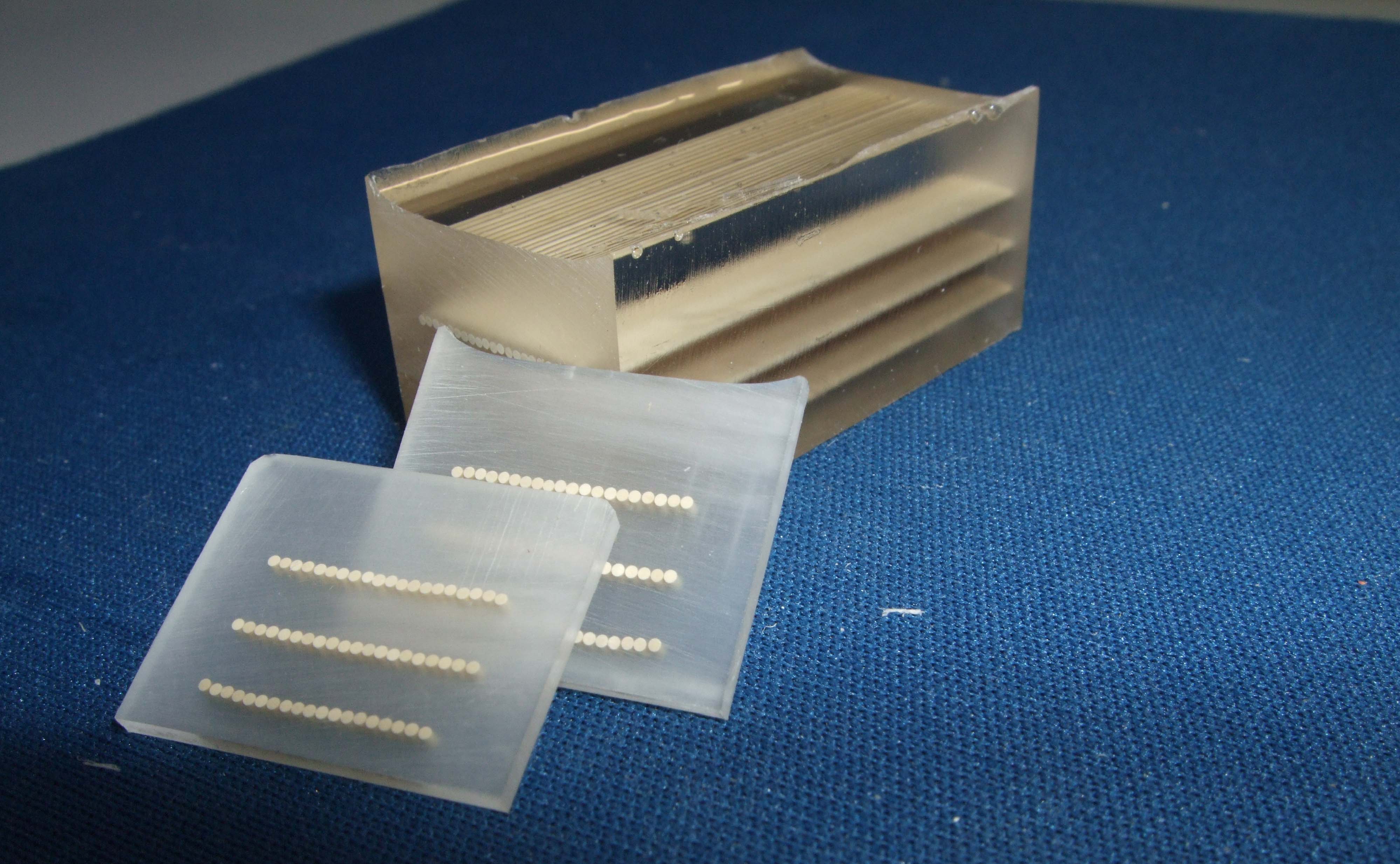

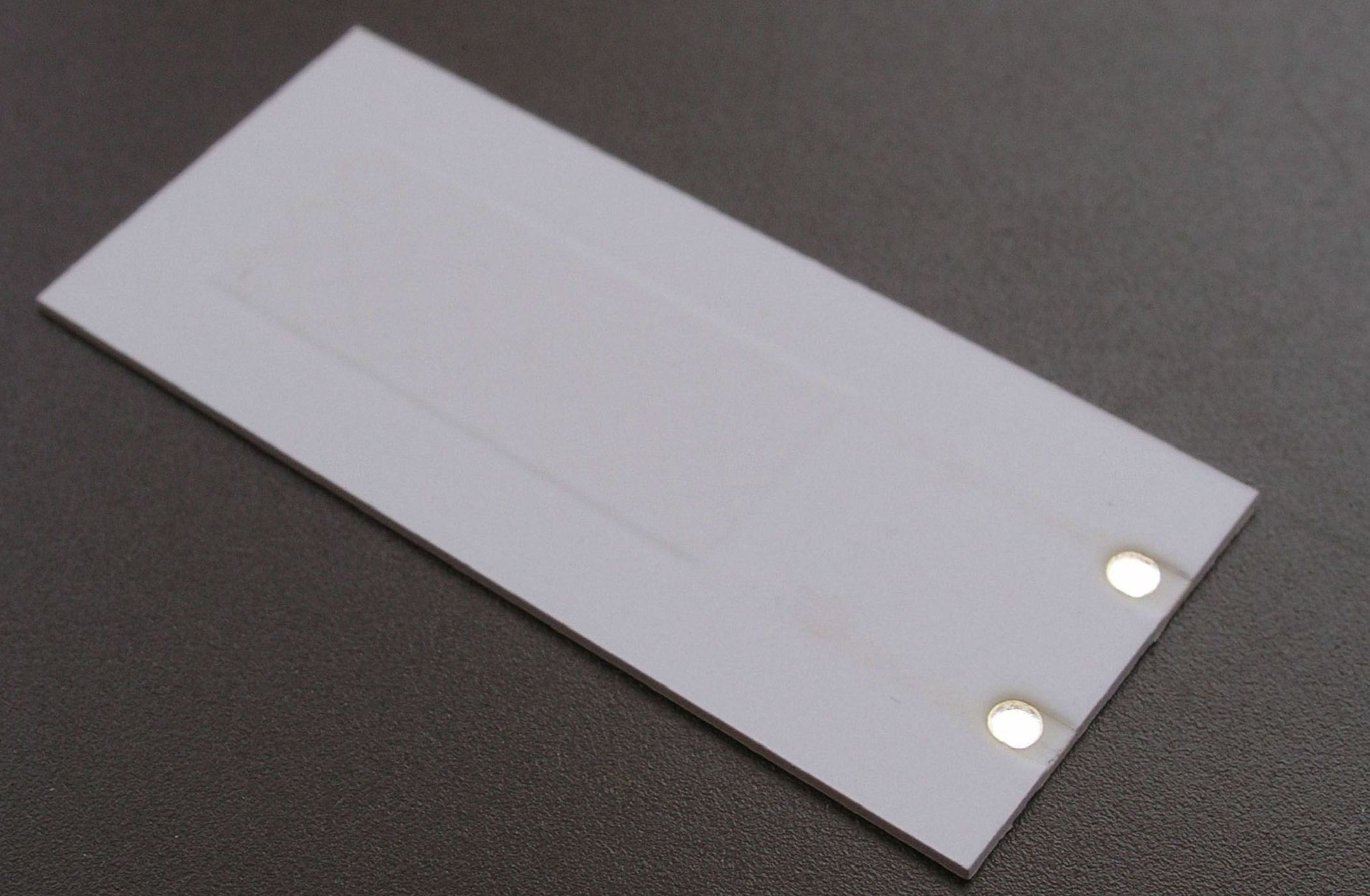

• Successful integration of LTCC/PZT modules into aluminum plates by die-casting. Solution of outer electrical termination by means of laser soldering has to be solved (fig. 10).

|

|

|

| fig. 8 | fig. 9 | fig. 10 |