Subproject B4

Robust manufacturing technologies for active thermoplastic composite structures with integrated piezoceramic modules

Project Managers:

Prof. Dr.-Ing. habil. Prof. E.h. Werner HufenbachTechnische Universität Dresden

Fakultät Maschinenwesen und

Fakultät Verkehrswissenschaften „Friedrich List“

Institut für Leichtbau und Kunststofftechnik (ILK)

01062 Dresden

Telephon: +49-(0)351 / 463 38142

Telefax: +49-(0)351 / 463 38143

E-Mail: ilk@ilk.mw.tu-dresden.de

Dr.-Ing. Niels Modler

Technische Universität Dresden

Fakultät Maschinenwesen und

Fakultät Verkehrswissenschaften „Friedrich List“

Institut für Leichtbau und Kunststofftechnik (ILK)

01062 Dresden

Telephon: +49-(0)351 / 463 38156

Telefax: +49-(0)351 / 463 38143

E-Mail: n.modler@ilk.mw.tu-dresden.de

High-performance applications increasingly have to fulfil high requirements concerning comfort and environmental compatibility. Here, fibre-reinforced thermoplastic composites with embedded piezoceramic modules offer specific advantages due to the possibility to actively control the structural damping and deformation behaviour. The use of these innovative materials enables the development of a new generation of active lightweight structures with material-integrated noise control or active vibration damping functionalities. At present, the lack of robust high-volume manufacturing technologies is a major obstacle for the intensive use of these new active composites especially in series applications.

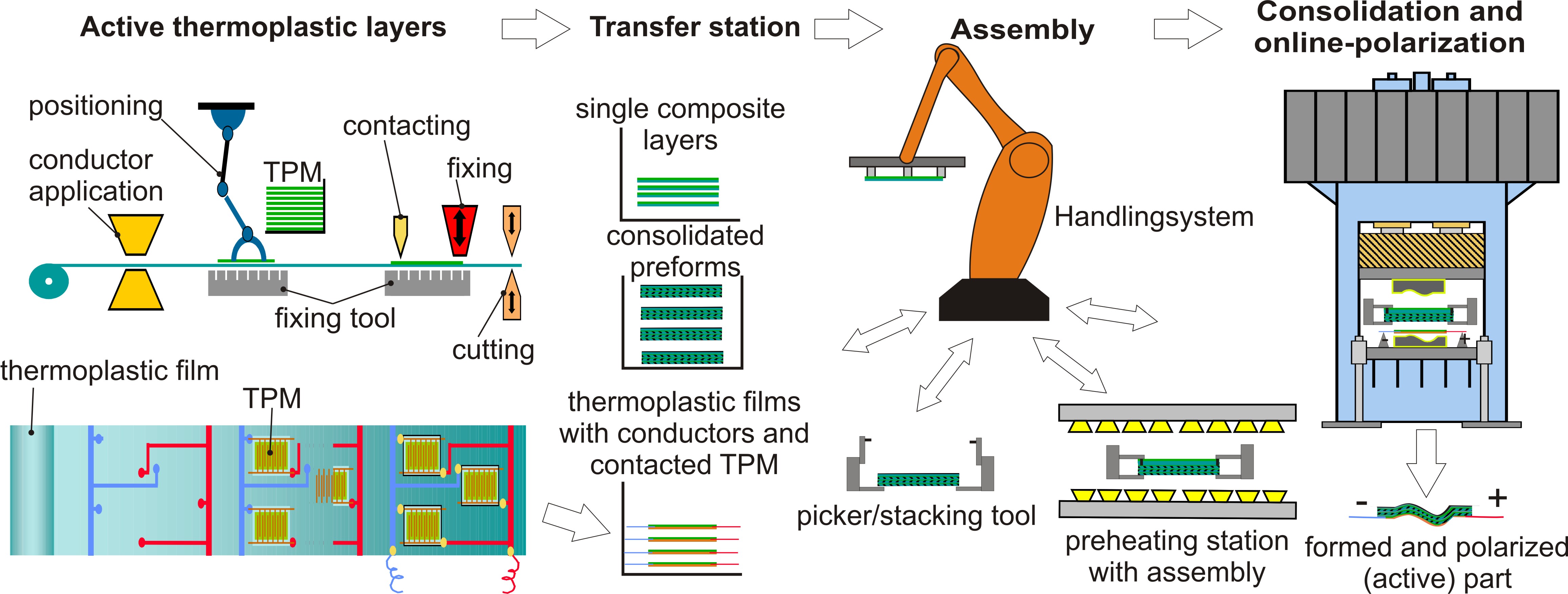

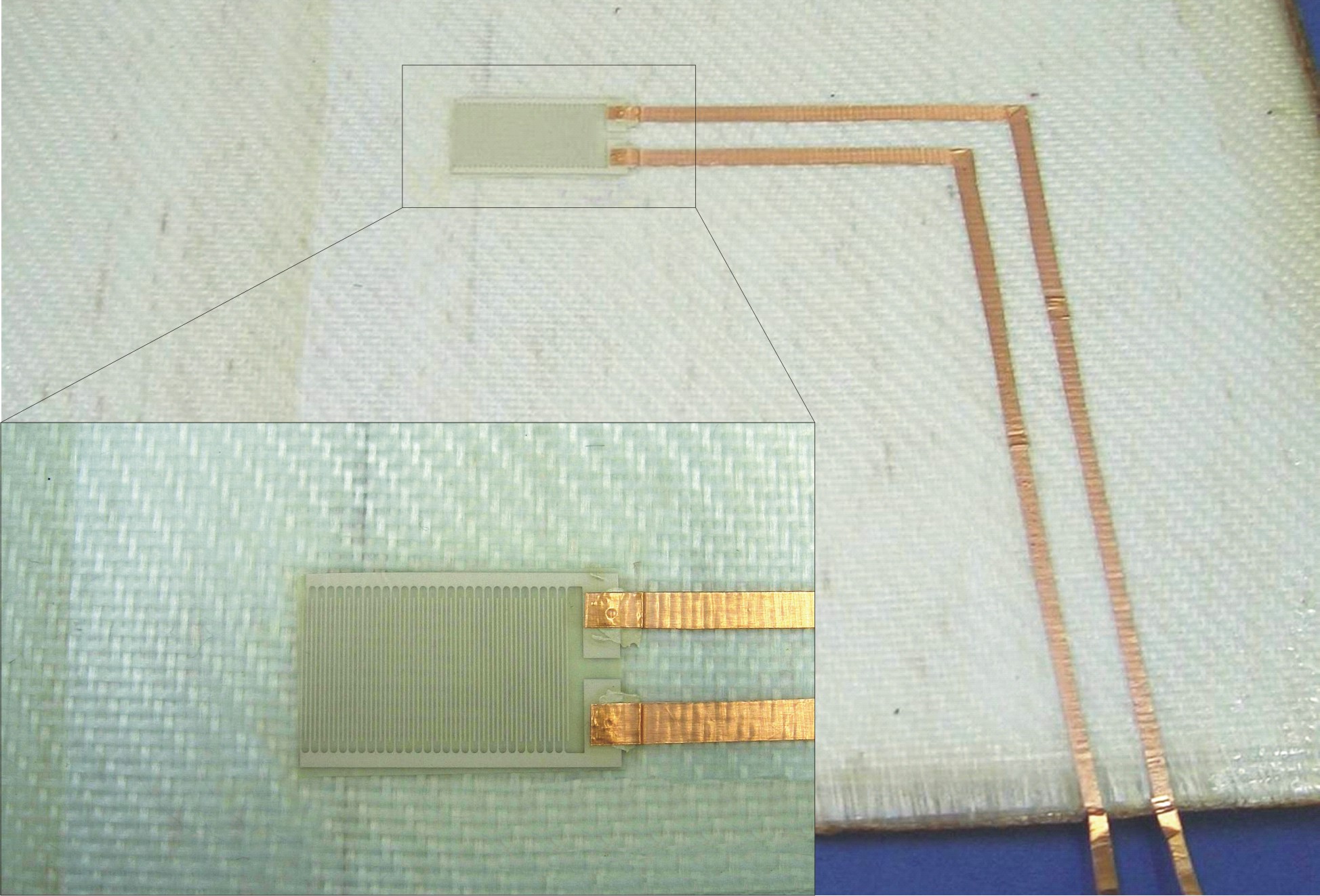

Main target of the project is the development of high-volume-compatible manufacturing technologies for active polyamide (PA) and polyetheretherketone (PEEK) composite structures with material-homogeneously embedded thermoplastic-compatible piezoceramic modules (TPM). Due to their excellent mechanical, thermal and biophysical properties, these novel active PA and PEEK composite components exhibit an innovation leading technology with wide influence on numerous fields of application. Figure 1: Process chain for automated manufacture of active thermoplastic composites In the first phase the technological fundamentals for the manufacture of plane basic components with embedded piezoceramic functional modules were acquired. Therefore, investigations regarding the development of robust processes based on the hot-pressing technology were performed, in which the material and process immanent advantages were systematically combined. Beside intensive process studies for the manufacture of plane specimens, in close collaboration with other subprojects fundamental investigations with regard to the process immanent contacting and gently actuator integration as well as the online-polarization of the TPM were performed. Substantial processing studies served for the analysis of different process parameter influences on the interface between matrix, reinforcement and piezoceramic. Thus the integral processing of the TPM, developed in subproject A5, to an active basis composite component was achieved, ready for operation without subsequent process steps. The novel direct technology is an excellent basis for the realization of a high-volume process chain for the manufacture of composite components with embedded piezoceramic sensors and actuators. Figure 2: Active glass fibre-PA-composite with embedded PA-TPM and conductors In the following the development of efficient manufacture technologies for curved structures is performed. Therefore, especially making-up technologies for the continuous high-volume integration of conductors, TPM-placement and contacting – short: „ePreforming“ – are investigated systematically. Furthermore, the connection of the single process steps with regard to a continuous process chain is realized and respective handling systems and adaptable multi-contour-tools are developed.