Subproject A4

Laser based electrical and mechanical contacting of composite materials with integrated active elements

Project Managers:

Prof. Dr.-Ing. Michael SchmidtFriedrich-Alexander-Universität Erlangen-Nürnberg

Lehrstuhl für Photonische Technologien

Paul-Gordan-Str.3

91052 Erlangen

Telephon: +49-(0)9131 / 85 23456

Telefax: +49-(0)9131 / 85 23234

E-Mail: michael.schmidt@lpt.uni-erlangen.de

Prof. i.R. Dr.-Ing. Dr.-Ing. E.h. mult. Dr. h.c. mult. Manfred Geiger

Bayerisches Laserzentrum GmbH

Konrad-Zuse-Straße 2-6

91052 Erlangen

Telephon: +49-(0)9131 / 97790 10

Telefax: +49-(0)9131 / 97790 11

E-Mail: m.geiger@blz.org

Motivation

Aim of the project

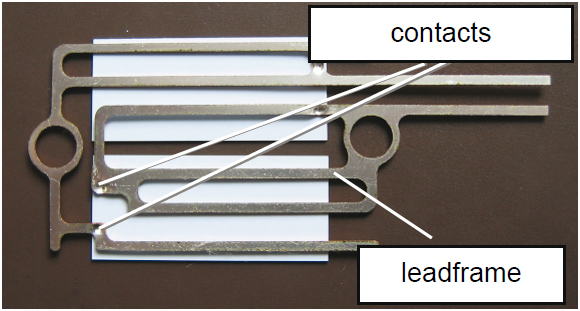

Fig 1: Contacts between a leadframe and a piezoceramic LTCC-module

Results and research programme

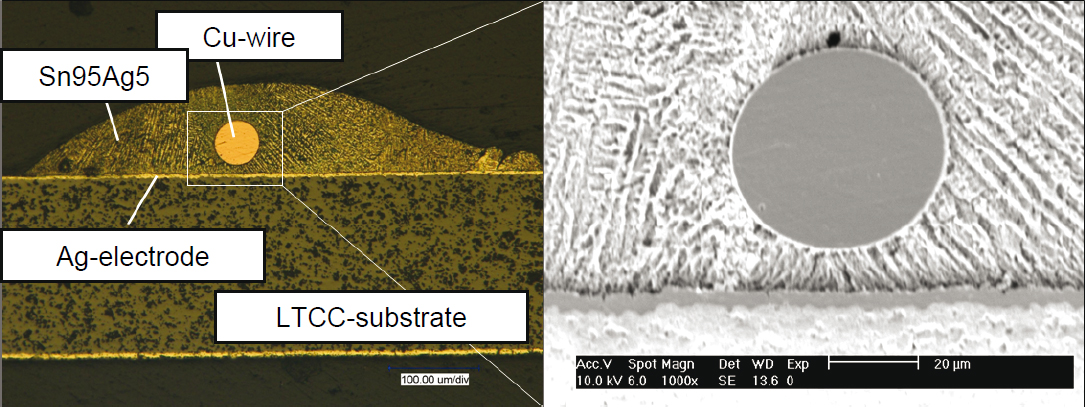

Fig 2: Cross-section of a solder joint on LTCC; solder Sn95Ag5

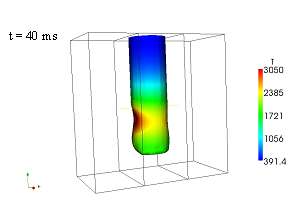

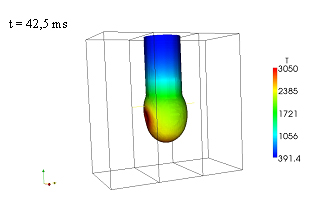

Fig. 3: Simulation result for the production of a droplet at the end of a brazing-wire for the derivation of process strategies for Laser Droplet Joining

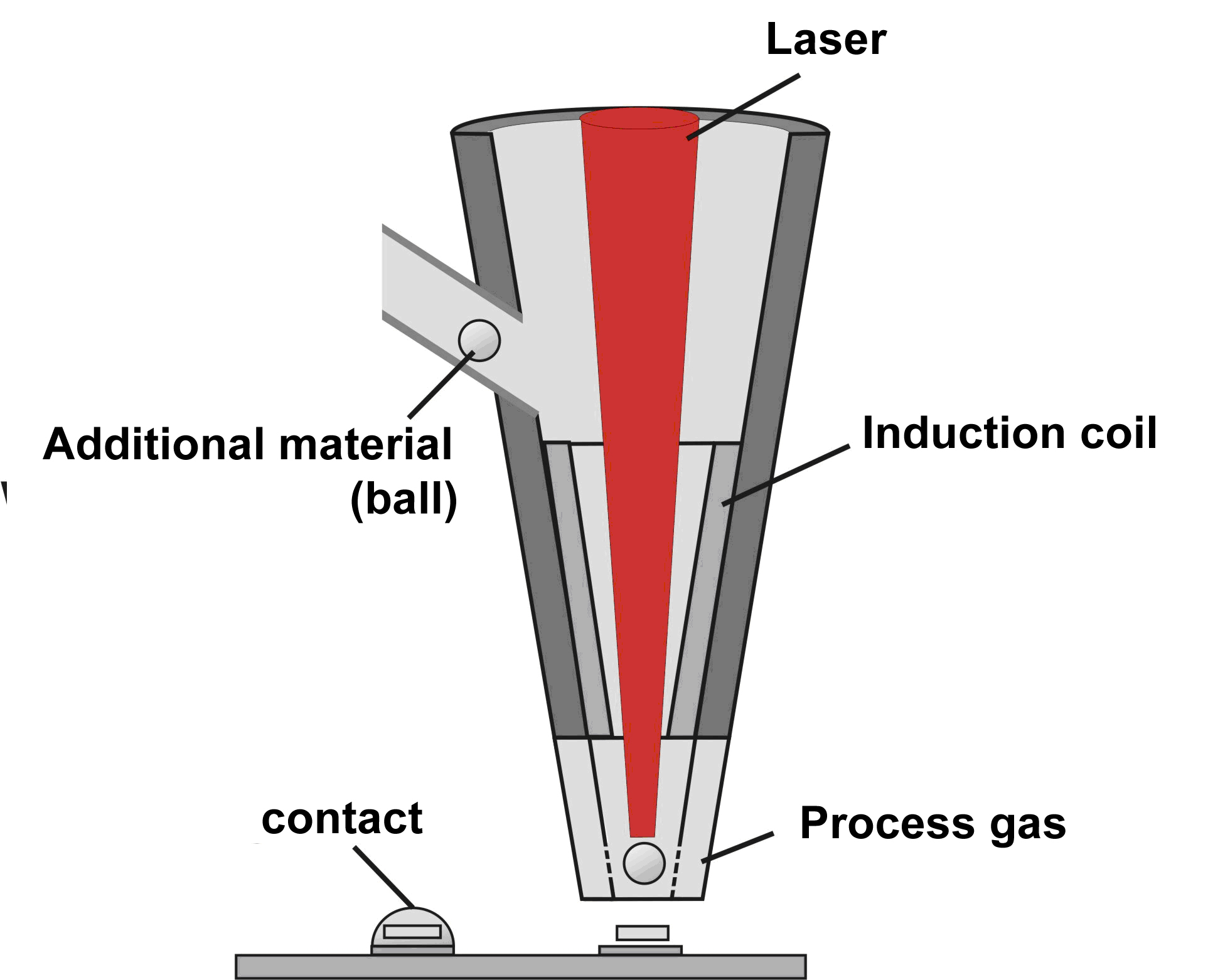

The research program in the second phase deals with the advancement of the Laser Droplet Joining to a special joining technology for the realization of brazing joints at piezoceramic modules. It is planned to use an additional material which is already supplied as a ball consisting of brazing material with a defined diameter. The melting of the ball will be carried out by induction warming and laser heating. By the already given dimension of the ball a reproducible adjustable droplet size is accessible. As the heat balance is linked to the droplet size, it will become adjustable and consequently allows a defined energy input into the piezoceramic modules. So delamination of the metallization and cracking of the modules should be avoided completely. A new system- and process-technology to contact piezoceramic modules suitable for series production should be realizable.

Methods

By experiments the basics for generating and supplying of liquid brazing balls will be examined. In addition dynamic process simulations will be carried out to explain the interaction mechanisms at the warming period and the droplet supply. By the help of analytic methods - for example by detecting the heat radiation - a scientific process description is possible.

Fig. 4: Schematic of the planned process head for Laser Droplet Joining

For a crack-free joining process the temperature fields and the resultant mechanical tensions on the piezoceramic modules are of special interest. Existing simulation models will be improved for a description of the interaction of the liquid brazing balls and the different piezoceramic modules of the SFB-TR 39. In relation to experimental studies the explanation of necessary strategies for a temperature control will be investigated.