Manufacturing Technologies of Functional Piezoelectric Components for Integration into Lightweight Structures

A. Michaelis, S. Gebhardt

Aims

Manufacturing and characterization of functional piezoelectric components for integration into lightweight structures. Component design and customization with regard to adaptive functions and requirements resulting from the integration process.

- Development and manufacturing of volume and layer based piezoceramic-polymer-composites (PPV)

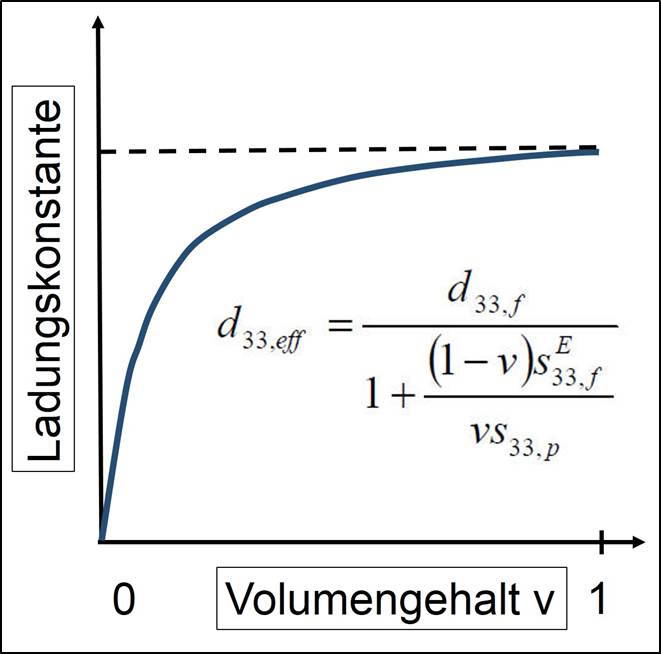

- Characterization and evaluation of effective properties of PPV in dependence on geometry and connectivity

- Research on electric field distribution of PPV during poling / piezoelectric response of PPV in operation (Coop. TP C03)

- Assessment of functional performance of PPV with regard to application

- Preparation of functional components for integration into lightweight structures

Results

Piezoelectric Fibers

Serial production of PZT fibers- Development of fiber spinning facility capable for serial production

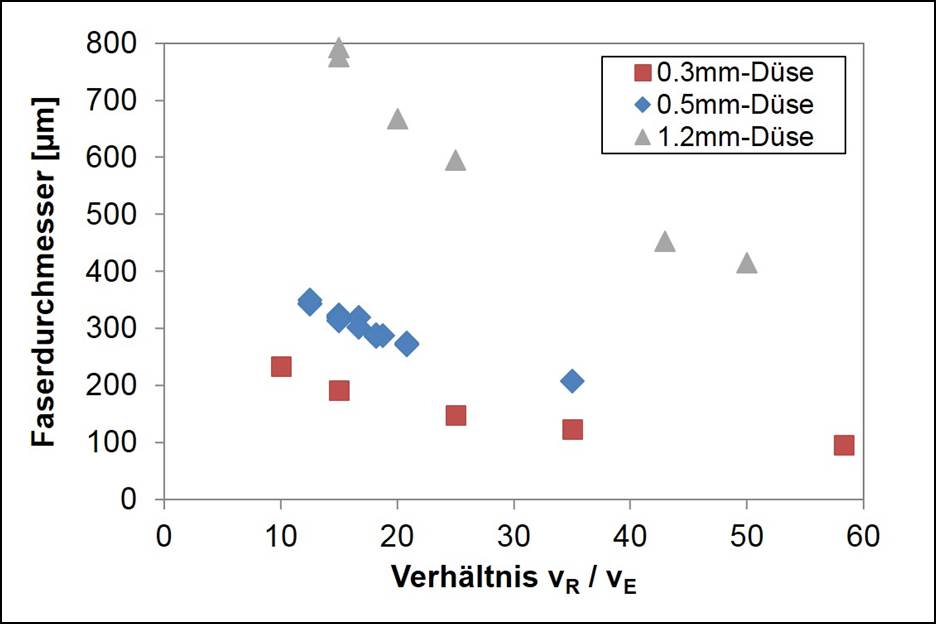

- Determination of process paramters for fabrication of PZT fibers with d = 100 - 800 µm (Fig. 1)

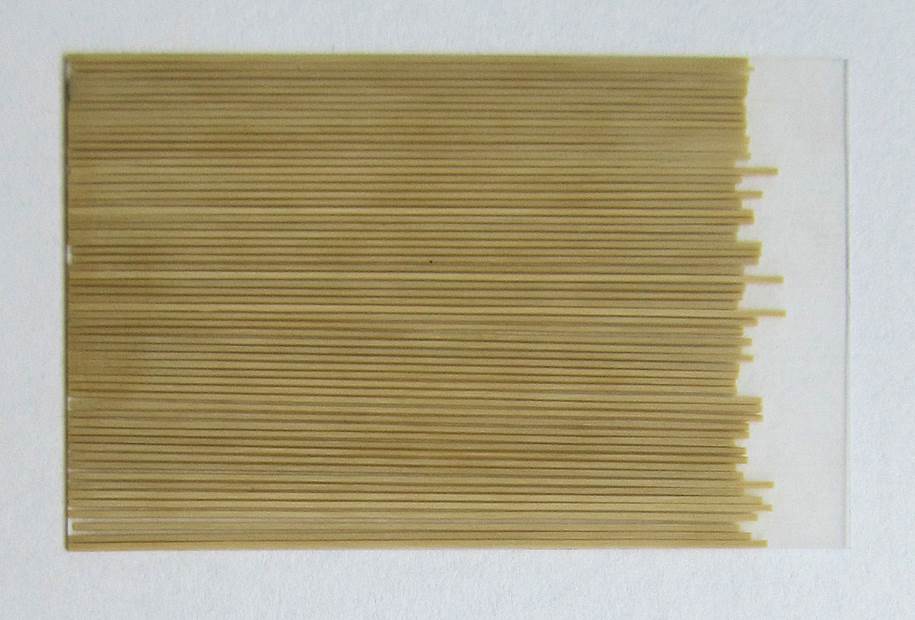

Fiber composites (Fig. 2) for integration into thermoplastic compounds

- Development of alignment technology for PZT fiber monolayer

- Improvement of fiber-matrix adhesion (Coop. IPF Dresden)

Fiber composites for integration into micro-structured aluminum sheet metals

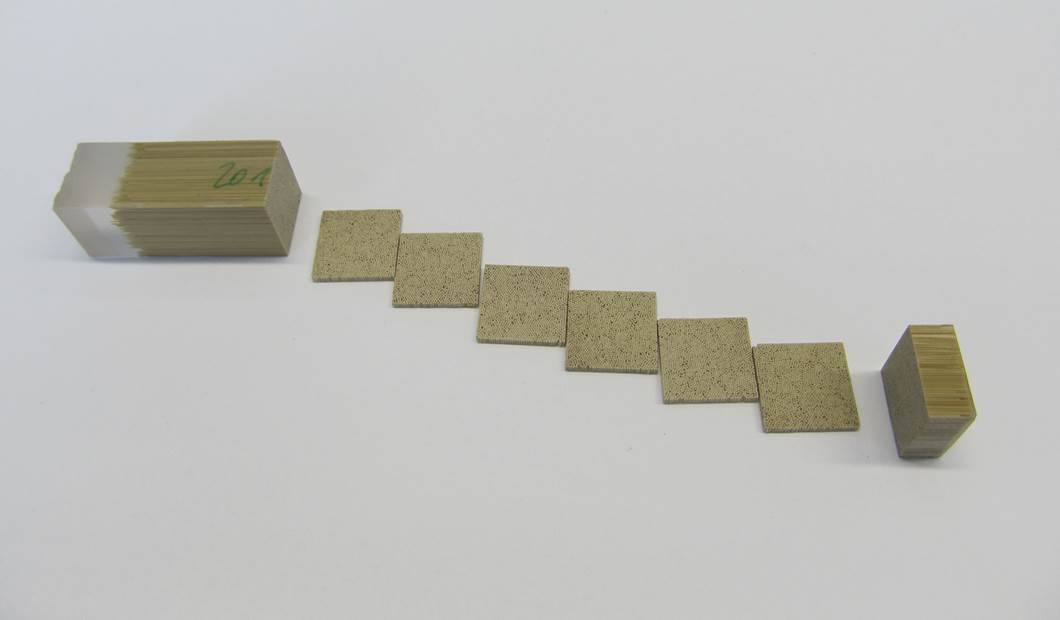

- Fabrication of 1-3 piezofiber composites by infiltration of aligned fibers with Araldite 2020 epoxy (Fig. 3)

Fig. 1 : Fiber diameter versus velocity ratio vR / vE

|

Fig. 2: Monolayer piezofiber composite for integration into thermoplastic compounds

|

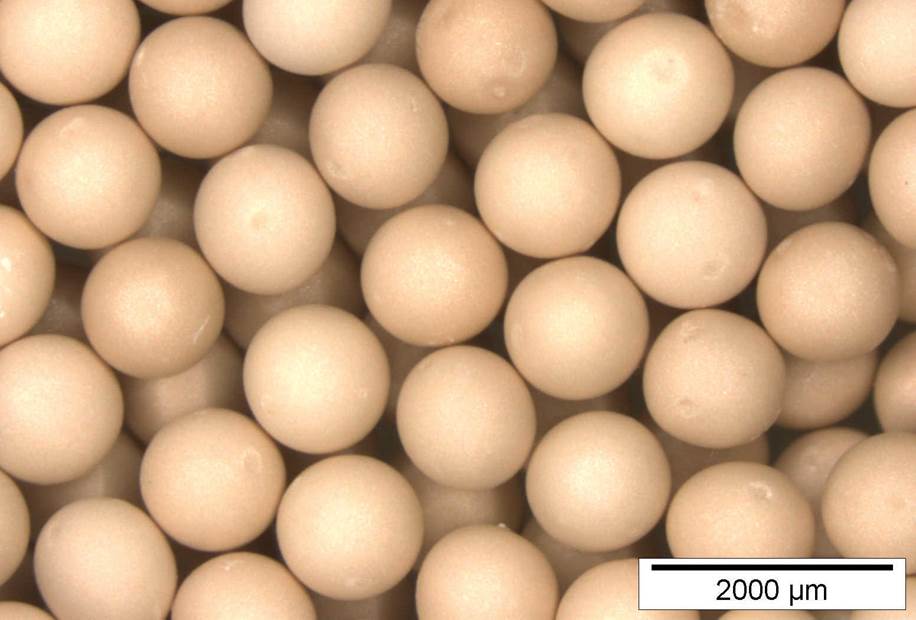

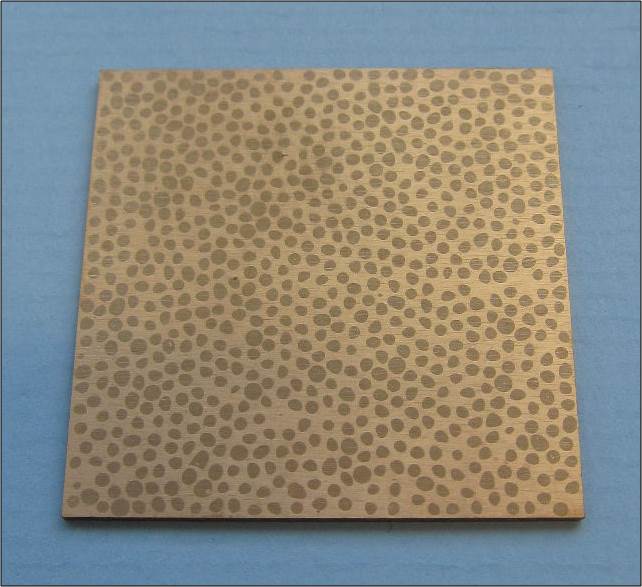

Novel piezoceramic components for integration into glass fiber polyurethan compounds

- Development of new process technology for fabrication of PZT pearls (Fig. 4)

Characterization of mechanical and electrical properties

- Mechanical parameters studied on single fibers

- Electrical parameters studied on 1-3 piezofiber composites

Fig. 3: 1-3 piezofiber composite block and diced composite discs

|

Fig.4: Sintered PZT pearls (diameter d ~ 1200 µm)

|

Piezoelectric Laminates

LTCC/PZT modules for integration into aluminum die casting parts- Adjustment of layout and design with regard to geometry and electrical termination

- Development of hybrid insert for damage-free integration

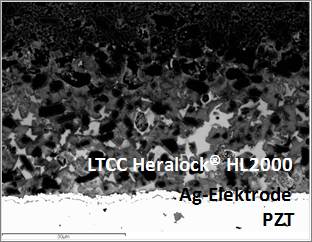

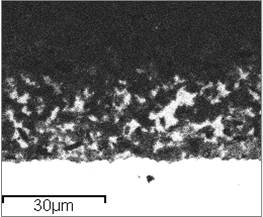

Chemical interaction between LTCC and PZT (Fig. 5 and 6)

- Characterization of element distribution at LTCC/PZT interface using energy dispersive X-ray spectroscopy (EDX)

- Degradation of PZT properties caused by diffusion of Pb into LTCC (formation of liquid phases in CaSiO3-PbSiO3 system)

Fig. 5: SEM image (BSE) of PZT/LTCC interface |

Fig. 6: EDX image of element distribution: Pb (pale areas) |

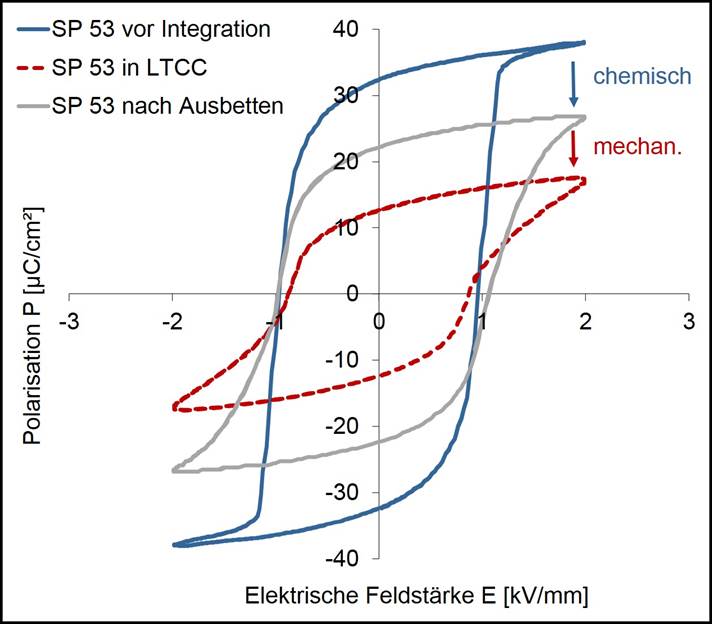

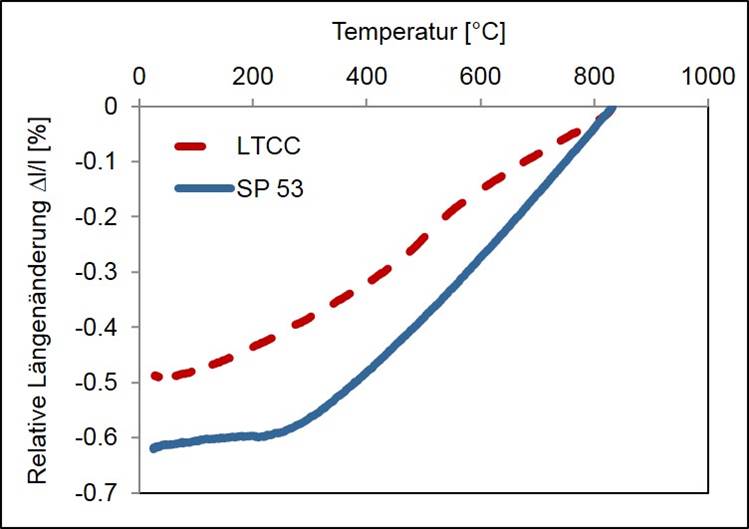

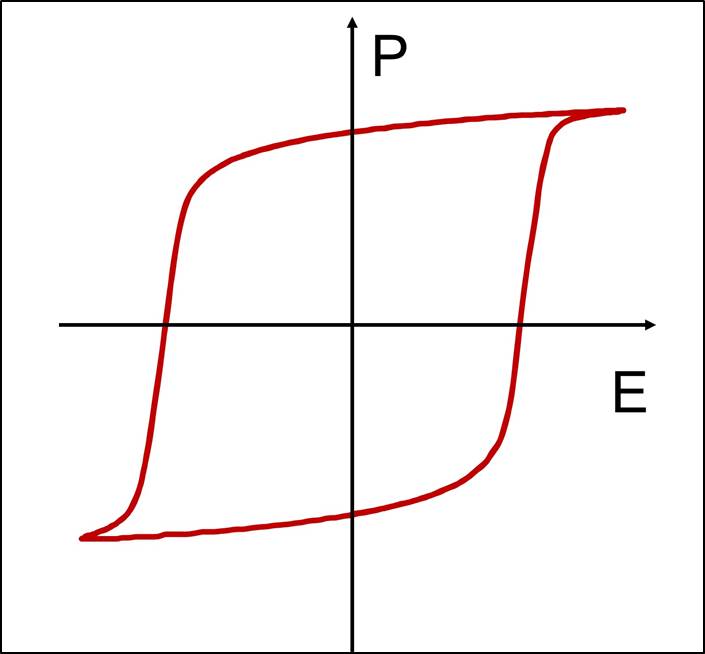

Mechanical interaction in LTCC/PZT compound (Fig. 7 and 8)

(Co-operation with TP C03)

- Measurement of polarization hysteresis of PZT before and after integration into LTCC

- Mechanical clamping of PZT caused by thermal expansion mismatch

Integration of additional functional components

- Development of “Acoustic Microsystems“ for transmitting and receiving of guided ultrasonic waves (SHM)

Fig. 7: Ferroelectric hysteresis of PZT SP53 before and after integration in LTCC, as well as after extraction |

Fig. 8: Relative thermal expansion of PZT SP 53 in |

Methods

|

Manufacturing of Functional Components |

|

|---|---|

|

PPV aus PZT-Perlen

|

|

Characterization of Properties |

|

|---|---|

|

Ferroelektrische Hysterese

|

|

Calculation of Material Parameters |

|

|---|---|

|

Ladungskonstante vs. Volumengehalt

|

|

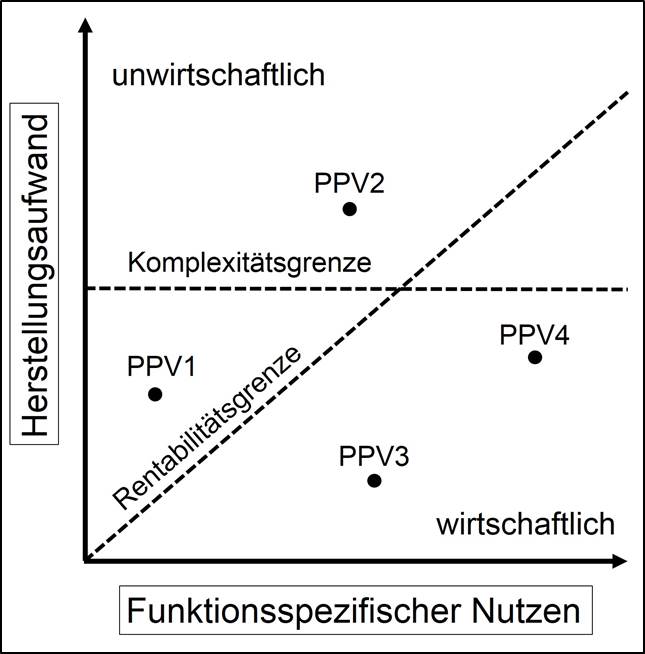

Evaluation |

|

|---|---|

|

Kosten-Nutzen-Analyse

|

Publications

Reviewed Publications

| [Hoh17] | Hohlfeld K: „Herstellung und Charakterisierung piezokeramischer Komponenten und daraus abgeleiteter Piezokomposite“. Doctoral thesis TU Dresden, In: Competencies in Ceramics, Vol. 38, Editor Alexander Michaelis, Fraunhofer Verlag Stuttgart, 2017 |

| [Zap15] | Zapf M , Hohlfeld K, Shah G, Gebhardt S, van Dongen K W A, Gemmeke H, Michaelis A, Ruiter N V: Evaluation of piezo composite based omnidirectional single fibre transducers for 3D USCT. In: Proc. IEEE International Ultrasonics Symposium (IUS) 2015, 21.-24. October, Taipei, Taiwan, 4 pages, DOI: 0.1109/ULTSYM.2015.0552 |

| [Flö10a] | Flössel M, Gebhardt S, Schönecker A, Michaelis A (2010) Development of a Novel Sensor- Actuator-Module with Ceramic Multilayer Technology. J Ceram Sci Tech 1(1):55-58 |

| [Geb12] | Gebhardt S, Flössel M, Schönecker A, Lieske U, Klesse T (2012) Robust Structural Health Monitoring Transducers Based on LTCC/PZT Multilayer. In: Proc ISAF-ECAPD-PFM 2012. Aveiro, Portugal. doi 10.1109/ISAF.2012.6297864 |

| [Geb13a] | Gebhardt S, Ernst D, Bramlage B, Flössel M, Schönecker A (2013) Integrated Piezoelectrics for Smart Microsystems – a Teamwork of Substrate and Piezo. Adv Sci Tech 77:1-10 |

| [Geb13b] | Gebhardt S, Flössel M, Schönecker A, Lieske U, Klesse T (2013) Compact Structural Health Monitoring Transducers Made by Ceramic Multilayer Technology. Ferroelectr 446(1):107-117 |

| Hohlfedl K, Gebhardt A, Schönecker A, Michaelis A. (2015) PZT components derived from poysulphone spinning process. In: Advances in Applied Ceramics; 114(4), 231-237. DOi: 10.1179/1743676114Y.0000000229 |

|

| [Hoh13a] | Hohlfeld K, Michaelis A, Gebhardt S (2013) Piezoelectric Transducers on the Basis of Free- Formed PZT Components. In: Joint UFFC-EFTF-PFM Symp. Prague, CZ, pp 279-282 |

| [Neu14] | Neumeister P, Eßlinger S, Gebhardt S, Schönecker A, Flössel M (2014) Effect of Mechanical Constraints in Thin Ceramic LTCC/PZT Multilayers on the Polarization Behavior of Embedded PZT. Int J Appl Ceram Technol (9pp), doi:10.1111/ijac.12218 |

| [Sch14] | Schwankl M, Rübner M, Flössel M, Gebhardt S, Michaelis A, Singer RF, Körner C (2013) Active functionality of piezoceramic modules integrated in aluminum high pressure die castings. Sens Actuators A 207:84-90 |

| [Suc11] | Suchaneck G, Hu W, Gerlach G, Flössel M, Gebhardt S, Schönecker A (2011) Non Destructive Evaluation of Polarization in LTCC/PZT Piezoelectric Modules by Thermal Wave Methods. Ferroelectr 420(1):25-29 |

Other publications

| Decker R, Rhein S, Heinrich M, Tröltzsch J, Gebhardt S, Kroll L, Michaelis A (2015): Development and characterization of piezo-active polypropylene compounds filled with PZT and CNT. In: Proc 5th Sci Symp CRC/Transregio 39. Dresden, Germany, pp 59-64 |

|

| Eßlinger S, Geller S, Hohlfeld K, Gebhardt S, Michaelis A, Gude M, Schönecker A, Neumeister P: Novel poling method for active fibre-reinforced polyurethane composites. In: Proc. 5. Wissenschaftliches Symposium des SFB/TR 39 PT-PIESA, 14.-16. September, 2015, Dresden, Germany, pp. 23-27 |

|

| [Flö10b] | Flössel M, Gebhardt S, Schönecker A, Michaelis A (2010) Novel Packaged LTCC/PZT Modules for Actuator and Sensor Applications. In: Proc ACTUATOR 10. Bremen, Germany, pp 586-589 |

| [Flö12] | Flössel M, Lieske U, Klesse T, Gebhardt S (2012) Ceramic Based Structural Health Monitoring (SHM) Modules for Rough Environment. In: Proc ACTUATOR 12, Bremen, Germany, pp 68-71 |

| Hohlfeld K, Zapf M, Shah G, Gebhardt S, Gemmeke H, Ruiter N V, Michaelis A: Fabrication of single fiber based piezocomposite transducers for 3D USCT. In: Proc. 5. Wissenschaftliches Symposium des SFB/TR 39 PT-PIESA, 14.-16. September, 2015, Dresden, Germany, pp. 95-99 |

|

| [Hoh13b] | Hohlfeld K, Gebhardt S, Michaelis A (2013) Free-formed Piezoceramic Components for Smart Structures. In: Proc 4th Sci Symp CRC/Transregio 39. Nuremberg, Germany, pp 19-24 |

| [Hoh13c] | Hohlfeld K, Gebhardt S, Schönecker A, Michaelis A (2013) Piezoceramic Fibers and Pearls Derived by the Polysulfone Spinning Process. In: Proc PIEZO 2013. Les Arcs, France, pp 9-12 |

| Stein S, Wedler J, Rhein S, Gebhardt S, Schmidt M, Körner C, Michaelis A (2015): Investigations on the process chain for the integration of piezoelectric ceramics into die casted aluminum structures. In: Proc 5th Sci Symp CRC/Transregio 39. Dresden, Germany, pp 65-69 |

|

| Weiß M, Ilg J, Hohlfeld K, Gebhardt S, Rupitsch S J, Lerch R, Michaelis A: Inverse Method for determining piezoelectric material parameters of piezoceramic fiber composites“. In: Proc. 5. Wissenschaftliches Symposium des SFB/TR 39 PT-PIESA, 14.-16. September, 2015, Dresden, Germany, pp. 77-82 |

|

| Zapf M , Hohlfeld K, Shah G, Gebhardt S, van Dongen K W A, Gemmeke H, Michaelis A, Ruiter N V: Evaluation of piezo composite based omnidirectional single fibre transducers for 3D USCT. In: Proc. IEEE International Ultrasonics Symposium (IUS) 2015, 21.-24. October, Taipei, Taiwan, 4 pages, DOI: 0.1109/ULTSYM.2015.0552 |

Patents

| [Sche11] | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung. Verfahren zur reproduzierbaren Herstellung keramischer Formkörper. Patentschrift DE102008056721B4. 2011-06-22 |

| [Schö13] | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung. Aktorisch wirksames oder aktorisch wirksames und sensitives Element. Patentschrift DE102007051075B4. 2013-10-17 |

Contact

Project Manager:Prof. Dr. rer. nat. habil. Alexander Michaelis

Technische Universität Dresden

Fakultät für Maschinenwesen

Institut für Werkstoffwissenschaft

Professur für Anorganisch-Nichtmetallische Werkstoffe

01062 Dresden

E-Mail: alexander.michaelis@…

Dr.-Ing. Sylvia Gebhardt

Fraunhofer-Institut für Keramische Technologien und Systeme IKTS

Abteilung Intelligente Materialien und Systeme

Winterbergstraße 28

01277 Dresden

E-Mail: sylvia.gebhardt@…