Design and Manufacturing of Fibre-Reinforced Structures with Integrated Actuator-Sensor-Arrays for Technical Measurement Applications

N. Modler, M. Dannemann

Aims

The main goal of the Transfer Project T03 is the application of the results of fundamental studies regarding fibre-reinforced components based on thermoplastic matrix materials with integrated piezoceramic modules obtained within the Collaborative Research Centre DFG-CRC/TR 39 to industrially applicable and economically manufacturable fibre-reinforced structures with material integrated actuator-sensor-arrays. This aim forces particularly the modification of the associated manufacturing technologies and design methods taking into account the industrial requirements such as the positioning accuracy, functionality and manufacturing cycle times.

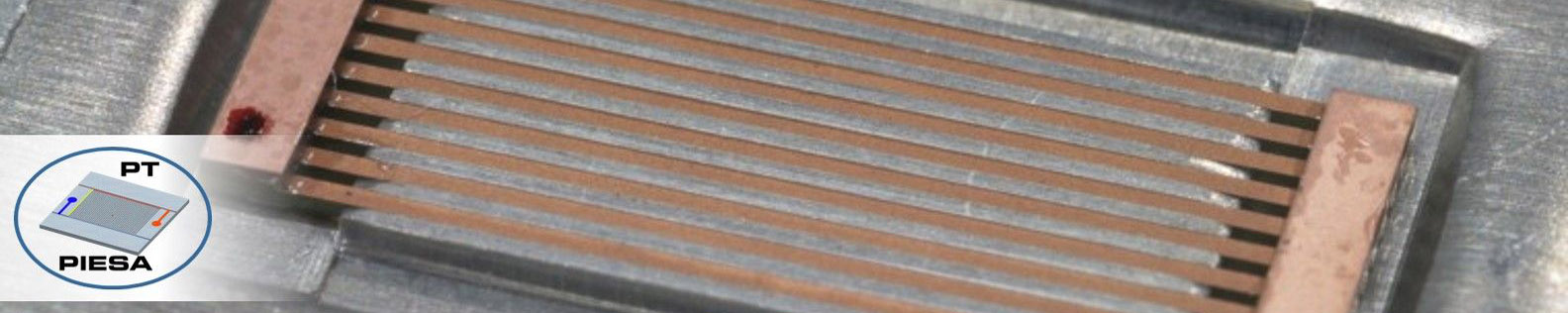

ePreform (TP B04) with actuator-sensor-array

Methods

| Property Determination | |

|---|---|

|

Set-up for the identification of electrical impedance of a thermoplastic-compatible piezoceramic module (TPM)TP A05

|

| Computational Models | |

|---|---|

|

Simulation of propagation of mechanical waves, which were generated by a material integrated actuator array

|

| Manufacturing Studies | |

|---|---|

|

Exemplary procedure for manufacturing of functionalised components

|

| Non-destructive testing and functional examination | |

|---|---|

|

Experimental modal analysis of a test structure excited using a TPM

|

Publications

Arbeiten mit wissenschaftlicher Qualitätssicherung

| [Dan12a] | Dannemann M (2012) Zur vibroakustischen Auslegung von Faserverbund-Leichtbaustrukturen. Dissertation, Technische Universität Dresden |

| [Huf10a] | Hufenbach W, Gude M, Modler N, Heber T, Tyczynski T (2010) Sensitivity analysis for the process integrated online polarization of piezoceramic modules in thermoplastic composites. Smart Mater Struct 19:105022(6pp) |

| [Huf11b] | Hufenbach W, Gude M, Modler N, Heber T, Tyczynski T, Winkler A (2011) Studien zur prozessimmanenten Online-Polarisation heißpresstechnisch integrierter piezokeramischer Aktuatoren in Thermoplastverbundstrukturen. In: 18. Symp Verbundwerkst Werkstoffverb. Chemnitz, S 289-295 |

| [Huf14] | Hufenbach W, Modler N, Winkler A (2013) Experimentelle Studien zur Entwicklung einer neuartigen e-preforming-Technologie für die großseriengerechte Fertigung aktiver Thermoplastverbundstrukturen. In: 19 Symp Verbundwerkst Werkstoffverb. Karlsruhe, S 413-421 |

| [Huf13a] | Hufenbach W, Modler N, Winkler A (2013) Experimentelle Studien zur Entwicklung einer neuartigen e-preforming-Technologie für die großseriengerechte Fertigung aktiver Thermoplastverbundstrukturen. In: 19 Symp Verbundwerkst Werkstoffverb. Karlsruhe, S 413-421 |

| [Huf13b] | Hufenbach W, Gude M, Modler N, Heber Th, Winkler A, Weber T (2013) Process Chain Modelling and Analysis for the High-Volume Production of Thermoplastic Composites with Embedded Piezoceramic Modules. Smart Mater Res 2013:Article ID 201631 (13pp) |

| [Huf13c] | Hufenbach W, Modler N, Winkler A (2013) Sensitivity analysis for the manufacturing of thermoplastic e-preforms for active textile reinforced thermoplastic composites. Proc Mater Sci 2:1-9 |

| [Mak13] | Makarenko V, Hufenbach W, Modler N, Dannemann M, Tokarev V (2013) Feedforward semi-active model-based control of a plate carrying concentrated masses. Proc Nat Aviation Univ 56(N3):79-90 |

| [Dan12b] | Dannemann M, Hufenbach W, Friedrich J, Friebe S, Kolbe F (2012) Damping performance of composite structures with integrated viscoelastic layers – Simulation and experimental investigations. In: ICSV 19. Vilnius, Lithuania, pp 101-102 |

|

Winkler A, Dannemann M, Starke E, Holeczek K, Modler N:

Manufacturing and characterisation of fibre-reinforced thermoplastic composite structures with embedded piezoelectric sensor-actor-arrays for ultrasonic applications. In proceedings of 6th ETNDT (Emerging Technologies in NonDestructive Testing 6) (27.-29.05.2015), Brussels, Belgium

|

|

|

Holeczek, K.; Dannemann, M..; Modler, N.:

Auslegung reflexionsfreier Dämpfungsmaßnahmen für mechanische Festkörperwellen. VDI-Berichte, 3. VDI-Fachtagung Schwingungsdämpfung 2015, Tagung, Leonberg, 22.-23.09.2015, VDI-Verlag, Düsseldorf 2015

|

|

|

Holeczek, K.; Starke, E.; Dannemann, M.; Modler, N.; Winkler, A.:

Active fibre-reinforced thermoplastic composite components with embedded sensor-actuator arrays. Proceedings of, 5th Scientific Symposium of the Collaborative Research Center/Transregio 39 PT-PIESA, Dresden, Germany, 14-16.06, 2015.

|

|

|

Holeczek, K.; Starke, E.; Winkler, A.; Dannemann, M.; Modler, N.:

Numerical and experimental characterisation of fibre-reinforced thermoplastic composite structures with embedded piezoelectric sensor-actuator-arrays for ultrasonic applications. Applied sciences, 6 (2016) 1.

|

Andere Veröffentlichungen

| [Huf11d] | Hufenbach W, Dannemann M, Friedrich J (2011) Berechnung modaler Verlustfaktoren von Faserverbundstrukturen mit partiellen viskoelastischen Dämpfungsschichten. In: Schwingungsdämpfung 2011. VDI-Verlag, Düsseldorf, S 35-43 |

| [Dan11] | Dannemann M, Hufenbach W, Friedrich J, Paul A (2011) Angepasstes numerisches Simulationskonzept zur vibroakustischen Optimierung von Faserverbundpropellern mit integrierten viskoelastischen Zwischenlagen In: 37. DAGA. Düsseldorf, Deutschland, S 543-544 |

| [Win13] | Winkler A, Marschner U, Starke E, Modler N, Fischer W-J, Hufenbach W (2013) Linear tow-port model of an active thermoplastic composite structure. In: Proc ASME Conf SMASIS, Snowbird, USA, PaperID SMASIS2013-3310 |

| Starke E, Dannemann M, Winkler A, Modler N, Holeczek K: Herstellung und Charakterisierung von Faserverbundstrukturen mit integrierten piezoelektrischen Wandlerarrays für die gerichtete Abstrahlung von Ultraschall (DAGA 2015) |

|

| Kostka, P.; Holeczek, K.; Dannemann, M.: Strain-based design strategy for the optimal placement of piezoelectric elements for multi-modal vibration control. V ECCOMAS Thematic Conference on the Mechanical Response of Composites COMPOSITES 2015, S.R. Hallett and J.J.C. Remmers (Editors) |

|

| Winkler, A.; Dannemann, M.; Holeczek, K.; Modler, N.; Weiß, M.; Rupitsch, S.: Directional radiation of acoustic waves using piezoelectric sensor-actuator-arrays embedded into textile-reinforced thermoplastics. Proceedings of, European Conference for Composite Materials (ECCM17), Munich,Germany, 26.-30.06, 2016. |

Patente

| [Mod13] | Leichtbau-Zentrum Sachsen GmbH. Anordnung und Verfahren zur direkten Erzeugung eines sensorisch- aktorischen Elements in adaptiven Bauteilstrukturen. Patentanmeldung DE102011010313A1. 2010-02-03 |

| [Sch11] | Technische Universität Dresden, Volkswagen AG. Kraftfahrzeug-Beleuchtungsvorrichtung. Patentanmeldung DE102011121252A1. 2011-12-15 |

| Winkler, A., Holeczek, K., Modler, N., “Verfahren zur Herstellung von mechanisch-elektrischen Fügeverbindungen zwischen mindestens zwei elektrische leitenden Verbunden eines Verbundsystems und multifunktionales Verbundsystem,” October 23, 2015. |

Application Partners

thyssenkrupp AG Tech Center Carbon Composites (TCCC)

|

|

ThyssenKrupp AG has established in April 2012, the TechCenter Carbon Composites (TCCC) in Dresden. The TCCC combines the expertise of the business group in the field of fibre reinforced plastics (FRP), brings together the current FRP projects and supports the group companies in the material selection field up to serial production. |

Qantos GmbH (QANTOS)

|

|

The core competence of the company Qantos GmbH lies in the processing of fibre reinforced plastics and in the manufacturing of complex system assemblies. QANTOS is a system supplier for customers in the areas of rail vehicles, cars and trucks and industry. The offer scope ranges from the development and design to the manufacturing of complete interior and exterior solutions. |

SPEKTRA Schwingungstechnik und Akustik GmbH Dresden (SPEKTRA)

|

|

The SPEKTRA Vibration and Acoustics GmbH Dresden is one of the leading manufacturers of instruments for sound and vibration measurements. Decades of experience in the field of "electrical measurement of mechanical values" has established in recent years SPEKTRA to a stable medium-sized company. In 2008 SPEKTRA overtook the APS Dynamics, a leading developer and manufacturer of shakers and systems for modal analysis, extreme low frequency calibration and components. |

Polytec GmbH (POLYTEC)

|

|

Polytec develops, manufactures and distributes laser-based measurement systems for industry and research for more than 40 years. With our non‑contact optical measuring systems, we help our customers to analyse mechanical vibrations, to determine length and speed in a mass‑process‑suitable manner and to characterise surface parameters and spectral material properties. Polytec is also a partner of leading international manufacturers for sales, application and service of products in the field of photonics and optical solutions. The key areas are the industrial image processing, optical telecommunications, spectral measurement, optical radiation measurement technology and laser and electro-optical test systems. Polytec was founded in Waldbronn near Karlsruhe in 1967 and has today over 350 employees worldwide maintaining offices in Europe, North America and Asia. |

Smart Material GmbH (SMG)

|

|

Smart Material GmbH focuses on the production, distribution and development of novel piezo composite components. In addition, it offers as products and services, software for the implementation and testing of piezoelectric composites. |

Carbon Composites e.V., Regionalabteilung CC Ost (CCO)

|

|

The regional division of CC Ost Carbon Composites e.V. strengthens and bundles – from the lightweight Campus Dresden – fibre composite skills of successful companies and research institutes located in eastern Germany. The area-of-interests of the regional division reaches currently from Saxony through Thuringia and Saxony-Anhalt to Brandenburg and Berlin. It is intended through the clustering to establish the still young high-performance fibre composite technology as the leading technology, bringing a sustainable source of growth and high-tech jobs. |

Contact

Project Manager:Prof. Dr.-Ing. Niels Modler

Technische Universität Dresden

Institut für Leichtbau und Kunststofftechnik

Holbeinstr. 3

01307 Dresden

E-Mail: niels.modler@…

Dr.-Ing. Martin Dannemann

Technische Universität Dresden

Institut für Leichtbau und Kunststofftechnik

Professur Strukturleichtbau und Kunststoffverarbeitung

Holbeinstr. 3

01307 Dresden

E-Mail: martin.dannemann@…