Mikrostrukturierung und automatisierte Fügetechnologien für Piezofasern in metallische Trägerwerkstoffe

A. Schubert, H.-J. Koriath

Aims

Increase of productivity and process reliability of microstructuring and joining processes for integration piezo fiber batches in metallic structures suitable for mass production process chains

- hybrid forming and joining processes with elastic tolerance compensation

- increase of process reliability and reproduction by using inherent sensor functionality of the piezo fibre batch for intelligent process control of the joining process

- process development of sealing technologies of the active zone to protect against media, mechanical damages and electrical insulation

Results

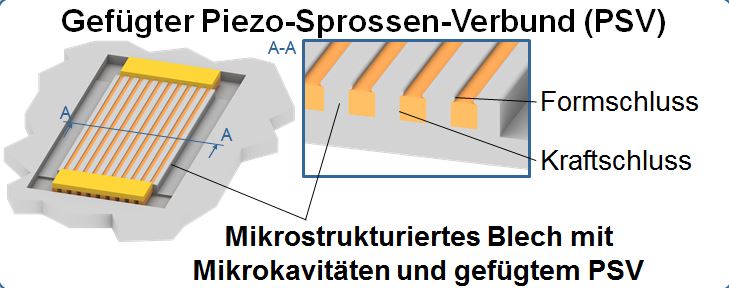

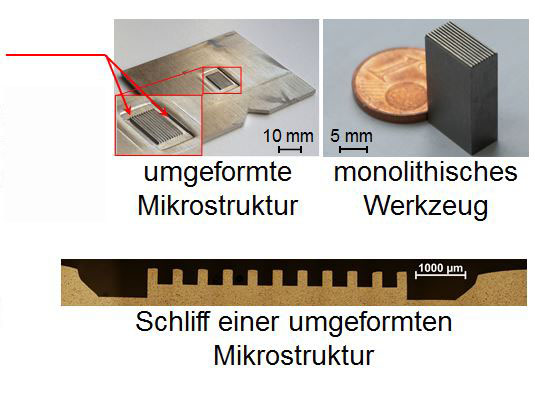

Microstructuring by micro forming

Micro impact extrusion

|

|

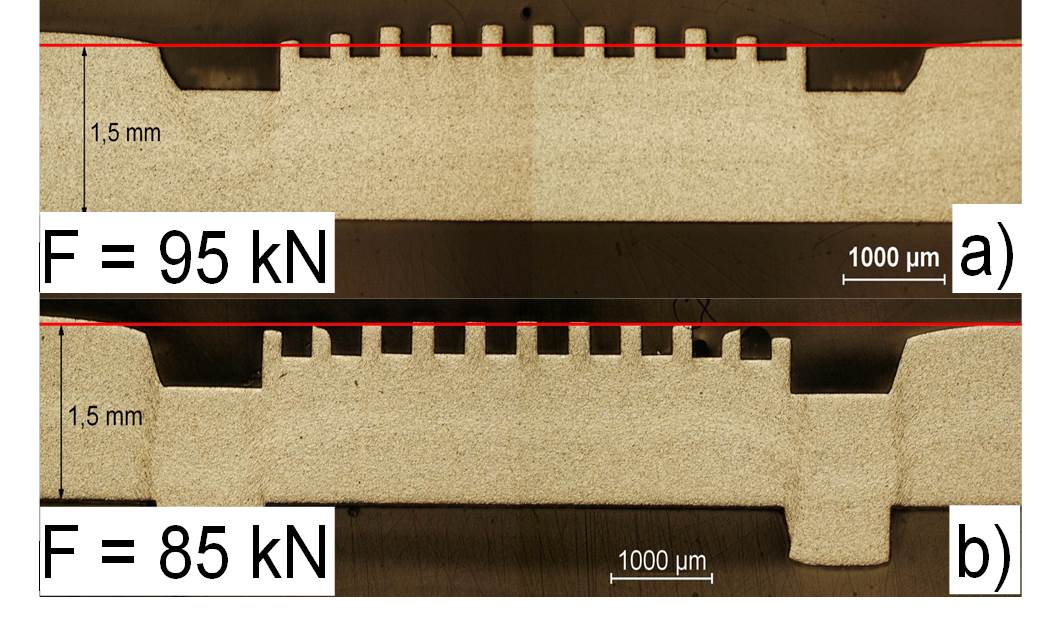

Hybrid Microforming

|

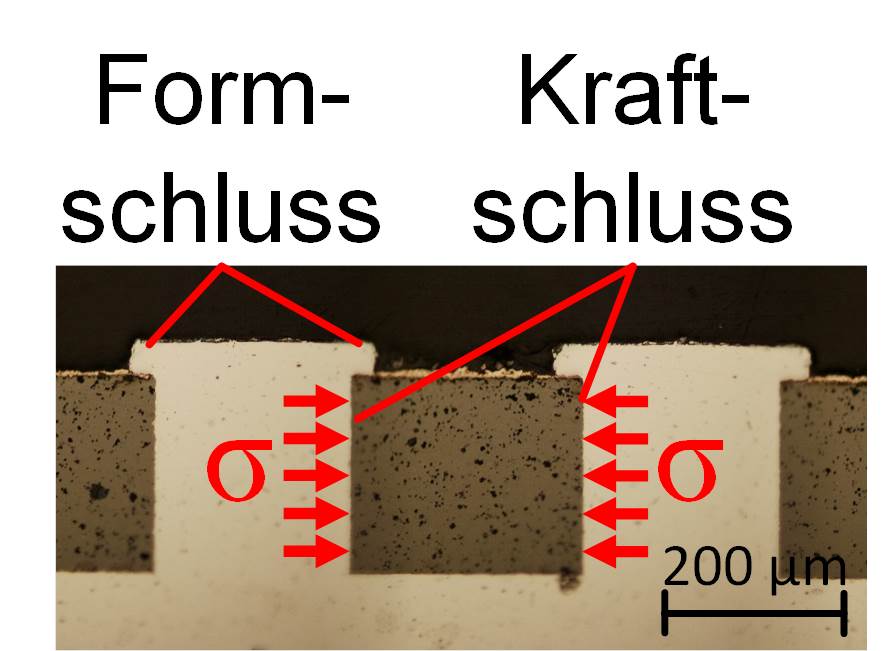

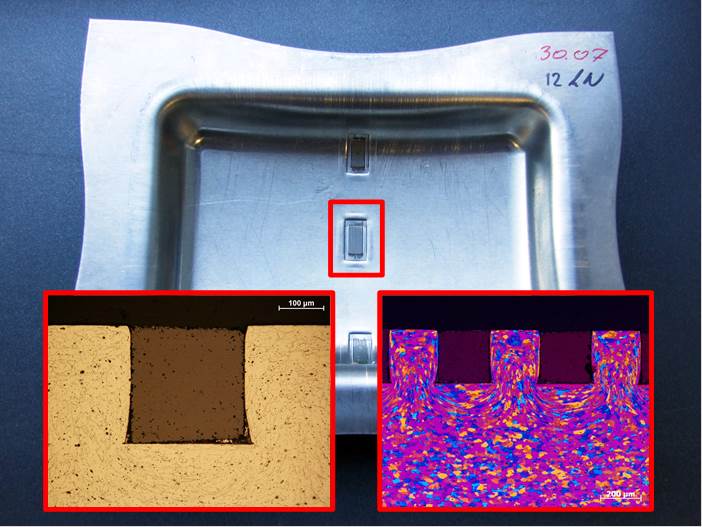

Micrograph a) Mmicro impact extrusion, b) hybrid forming, |

| Process input variables Investigation of:

|

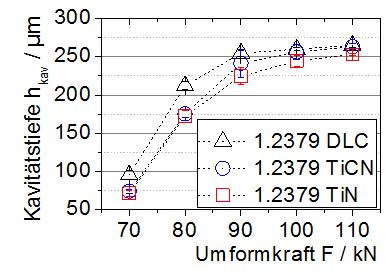

cavity depth in dependency on forming force and tool coating

|

Joining technologies

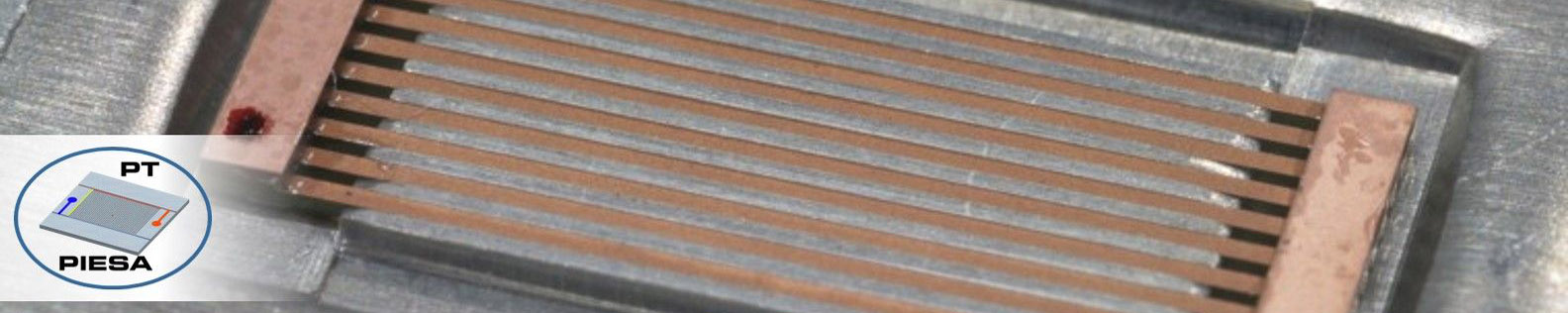

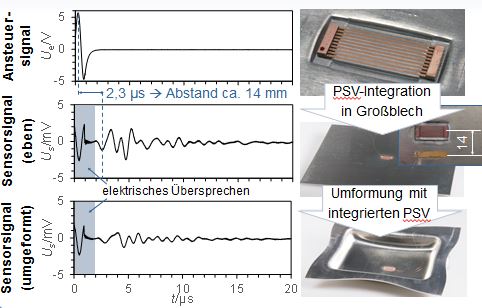

Joining of PSV

|

|

Deep drawing

|

|

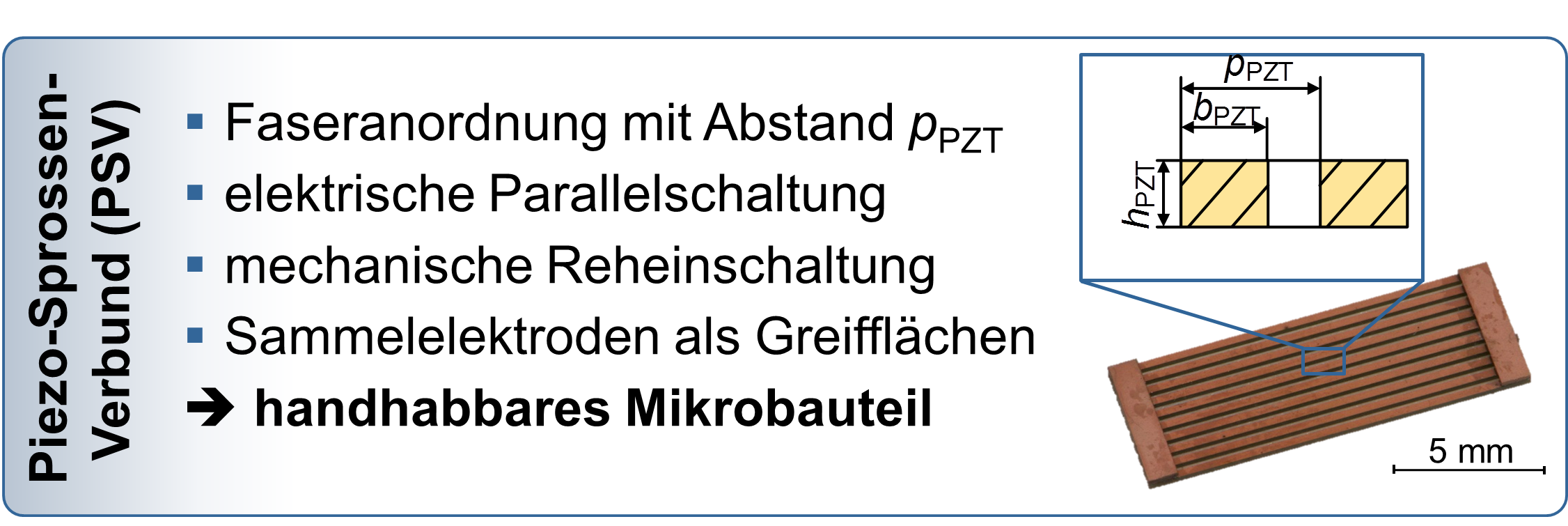

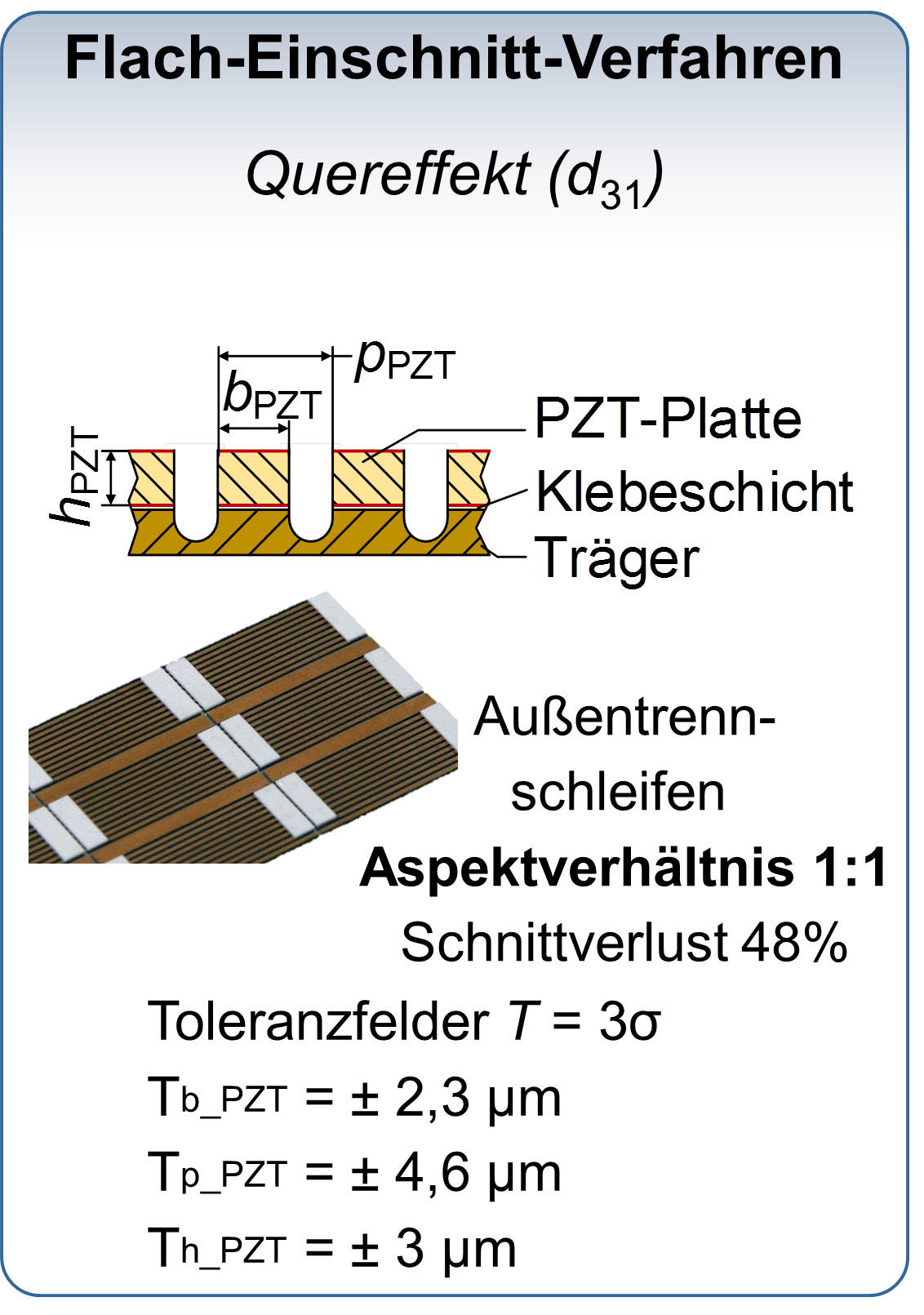

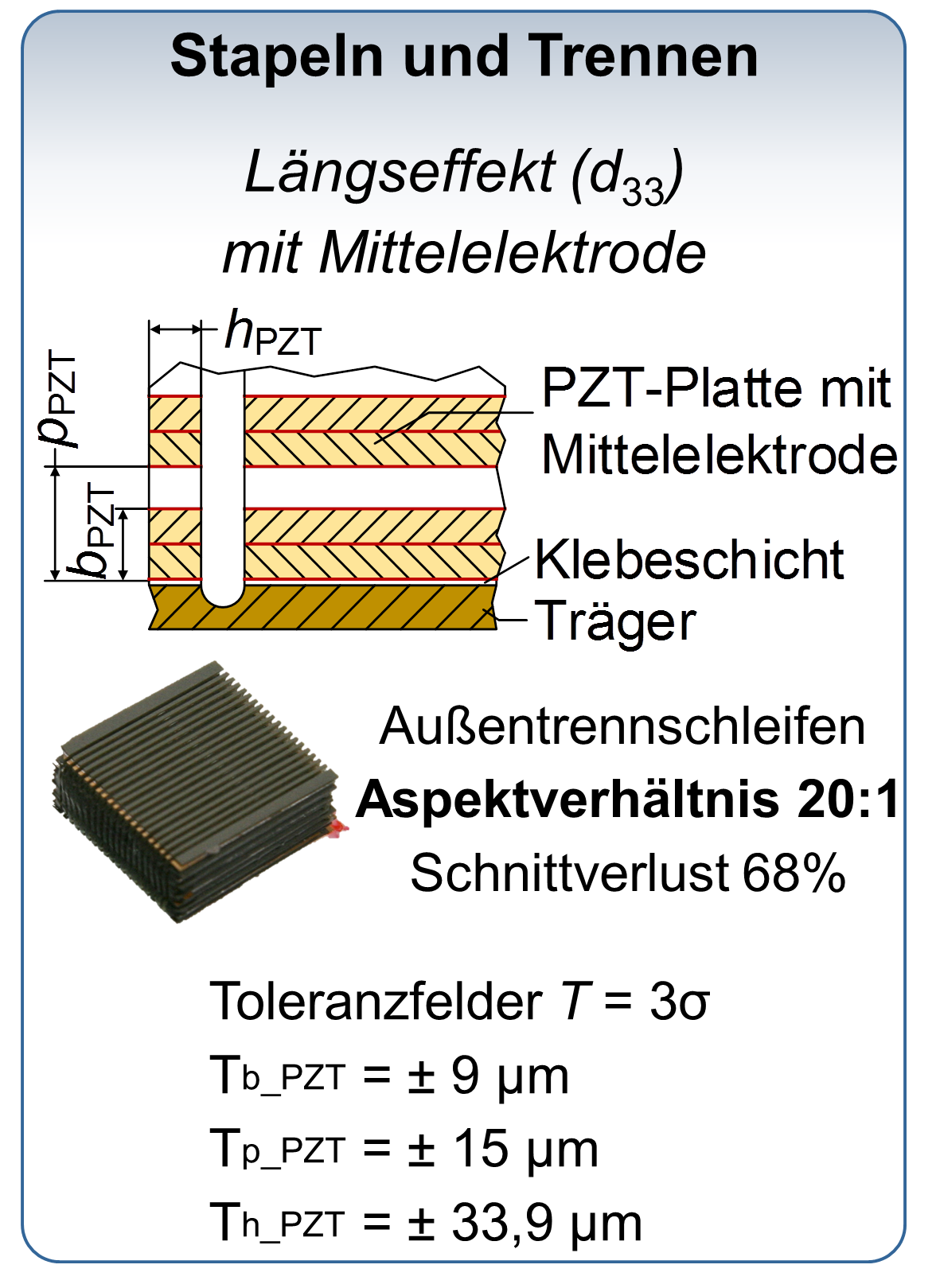

Fertigung und Montage von Piezo-Sprossen-Verbunden (PSV)

|

|

Automatisierte Mikromontage

|

|

Integrierte Piezo-Sprossen-Verbunde für die Strukturüberwachung (SHM)

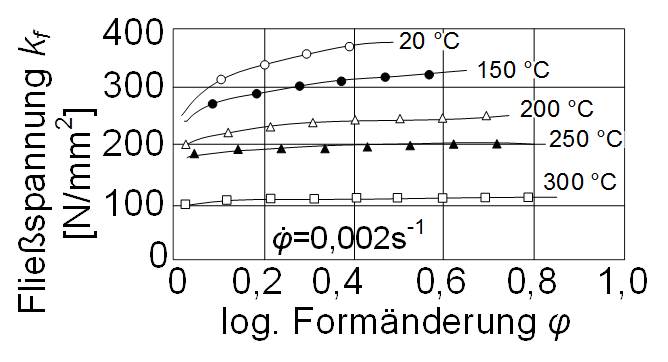

Methods

| Hybrid forming technologies | |

|---|---|

|

flow curves of EN-AW 5182

(according to Ostermann)

|

| Elastic tolerance compensation | |

|---|---|

|

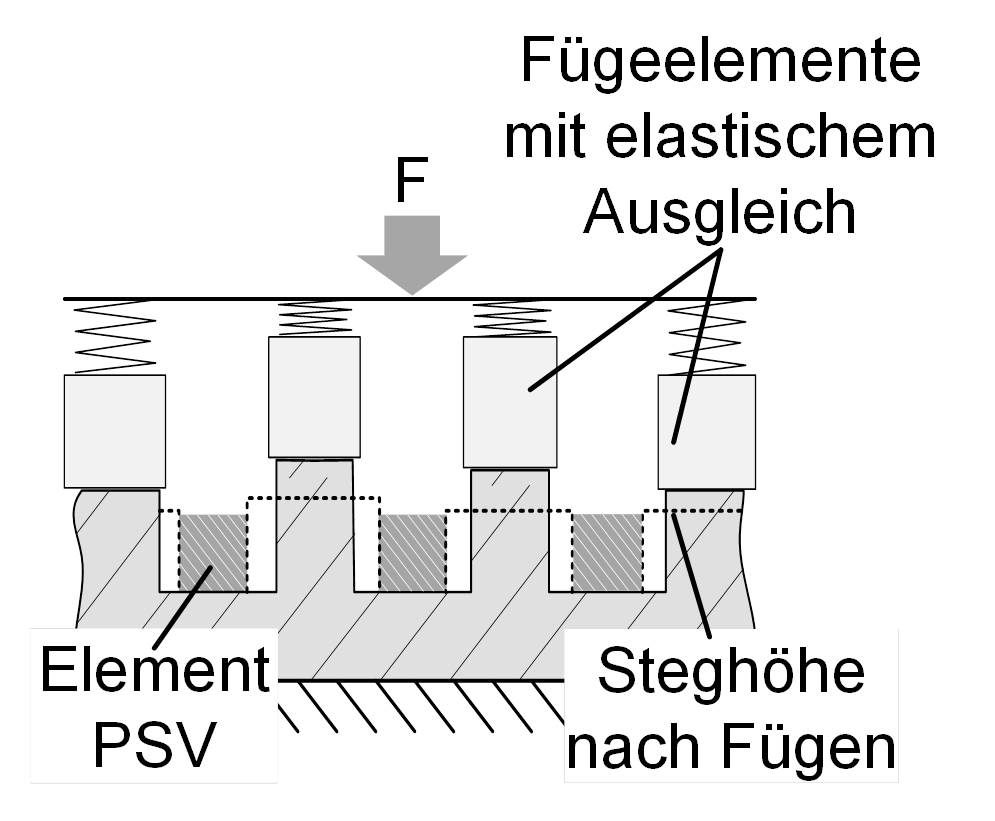

sketch of elastic tolerance compensation

|

| Process control with PSV as sensor | |

|---|---|

|

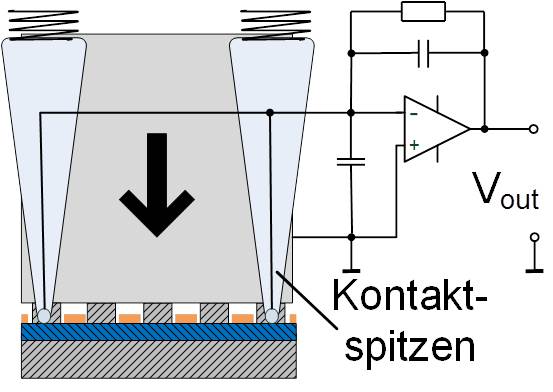

sketch of contacting during joining

|

| Charakterisierung von Eigenschaften | |

|---|---|

|

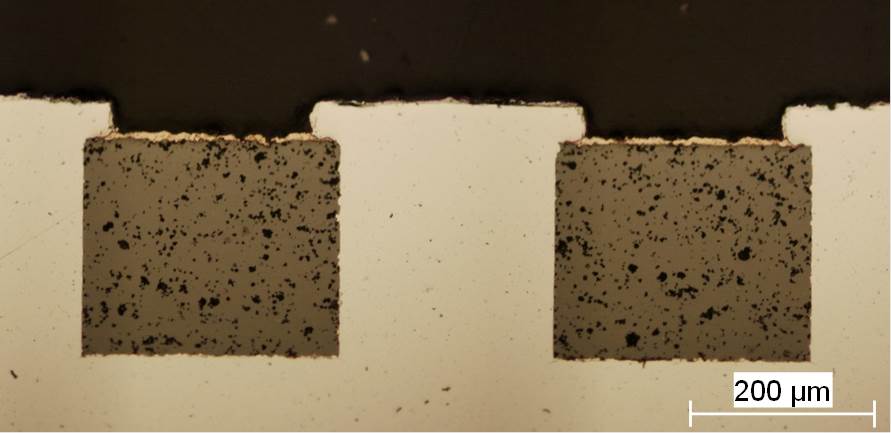

section of joined piezo ceramicelements |

| Functional test and quality assurance | |

|---|---|

|

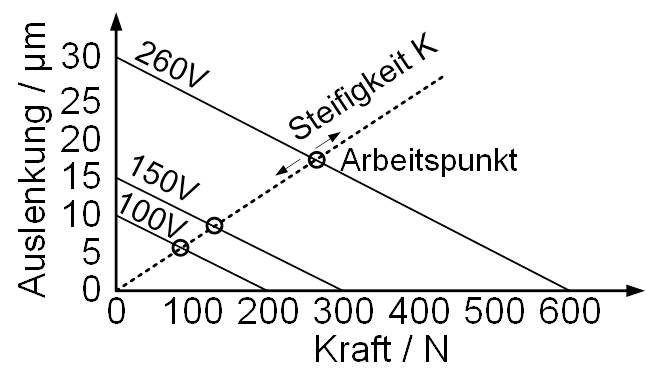

Kraft-Auslenkung-Kennfeld des Piezo-Metall-Verbunds

|

Publikationen

Reviewed Publications

| [Dro13] | Drossel W-G, Hensel S, Nestler M, Lachmann L, Schubert A, Müller M, Müller B (2014) Experimental and numerical study on shaping of aluminum sheets with integrated piezoceramic fibers. J Mater Process Technol 214(2):217-228 |

| [Sch13a] | Schubert A, Wittstock V, Jahn SF, Müller B, Müller M (2013) Joining by forming of piezoceramic macro-fiber arrays within micro-structured surfaces of aluminum sheets. Prod Eng, doi:10.1007/s11740-013-0498-7 |

| [Sch13b] | Schubert A, Wittstock V, Koriath H-J, Jahn SF, Peter S, Müller B, Müller M (2013) Smart Metal Sheets by Direct Functional Integration of Piezoceramic Fibers. Microsys Technol, doi:10.1007/s00542-013-1836-6 |

| [Sch13c] | Schubert A, Jahn SF, Müller B (2013) Microstructuring by a Combination of Micro Impact Extrusion and Shear Displacement Forming. Key Eng Mater 554-557:893-899 |

| [Neu13a] | Neugebauer R, Koriath H-J, Müller M (2013) Assembly of smart adaptronic piezo-metal composites by use of prefabricated batches of piezoceramic micro part. In: Proc. SPIE 8692, 869224 |

| [Sch14] | Schubert A, Jahn SF, Müller B (2014) Modular Tool Concept and Process Design for Micro Impact Extrusion. Prec Eng 38(1):57-63 |

Other publications

| [Neu13b] | Neugebauer R, Schubert A, Koriath H-J, Jahn SF, Müller B, Müller M (2013) Microfabricated piezo- metal substructures for sensor integration in large sheet metal parts. In: Proc 13th euspen, vol 2, pp 109-112 |

| [Sch13d] | Schubert A, Neugebauer R, Jahn SF, Müller M, Müller B (2013) Integration von Piezosensorik in Aluminiumbleche für das Structural Health Monitoring. In: 19. Symp Verbundwerkst Werkstoffverb, S 664-672 |

| [Sch12a] | Schubert A, Jahn SF, Müller B (2012) Umformende Mikrostrukturierung von Blechwerkstoffen für die Herstellung von Piezo-Metall-Modulen. In: Proc 4th ICAFT. Chemnitz, Germany, S 411-424 |

| [Sch12b] | Schubert A, Jahn SF, Müller B (2012) Influence of Different Tool Materials, Coatings and Lubricants onto Shape Accuracy during Micro Impact Extrusion. In: Proc 12th euspen, vol 2, pp 75-79 |

| [Neu11a] | Neugebauer R, Koriath H-J, Regel J, Müller M (2011) Process chain and tolerance management for precision manufacturing of piezo-metal-modules. In: Proc ISEM, pp 54(1)-54(12) |

| [Neu11b] | Neugebauer R, Koriath H-J, Richter M, Müller M (2011) Miniature 3-DOF planar parallel kinematics with large work space for precision positioning of endeffectors. In: Proc 11th euspen, vol 2, pp 315-318 |

Contact

Project Manager:Prof.Dr.-Ing. Andreas Schubert

Technische Universität Chemnitz

Fakultät für Maschinenwesen

Professur für Mikrofertigungstechnik (MFT)

09107 Chemnitz

E-Mail: andreas.schubert@…

Dr.-Ing. Hans-Joachim Koriath

Fraunhofer-Institut für Werkzeugmaschinen und Umformtechnik IWU

Reichenhainer Str. 88

09126 Chemnitz

E-Mail: koriath@…