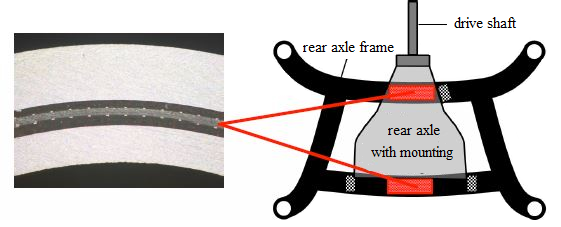

Active vibration control on structural components of a rear axle using integrated piezo actuators to reduce gear whine noise

W.-G. Drossel

Aims

Solution for the goal conflict between lightweight design, driving dynamics, drive and noise comfort in form of structurally integrated piezo-actuator applied on a rear axle assembly for active noise and vibration control.

|

|

Methods

|

Modeling and Simulation |

||

|---|---|---|

|

|

|

|

Experimental Verification |

||

|---|---|---|

|

rear axle

test rig |

|

|

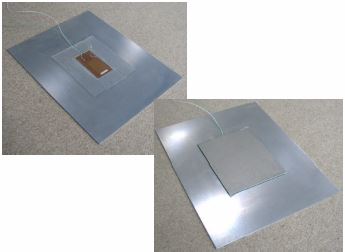

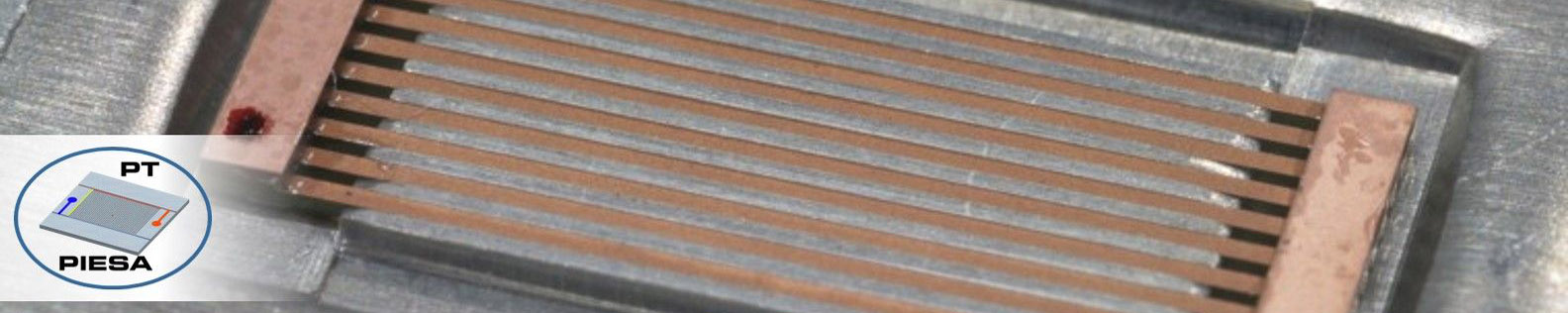

Piezointegration in Sheet Metal Parts |

||

|---|---|---|

|

Semi-

manufacturing with local cover sheet |

|

|

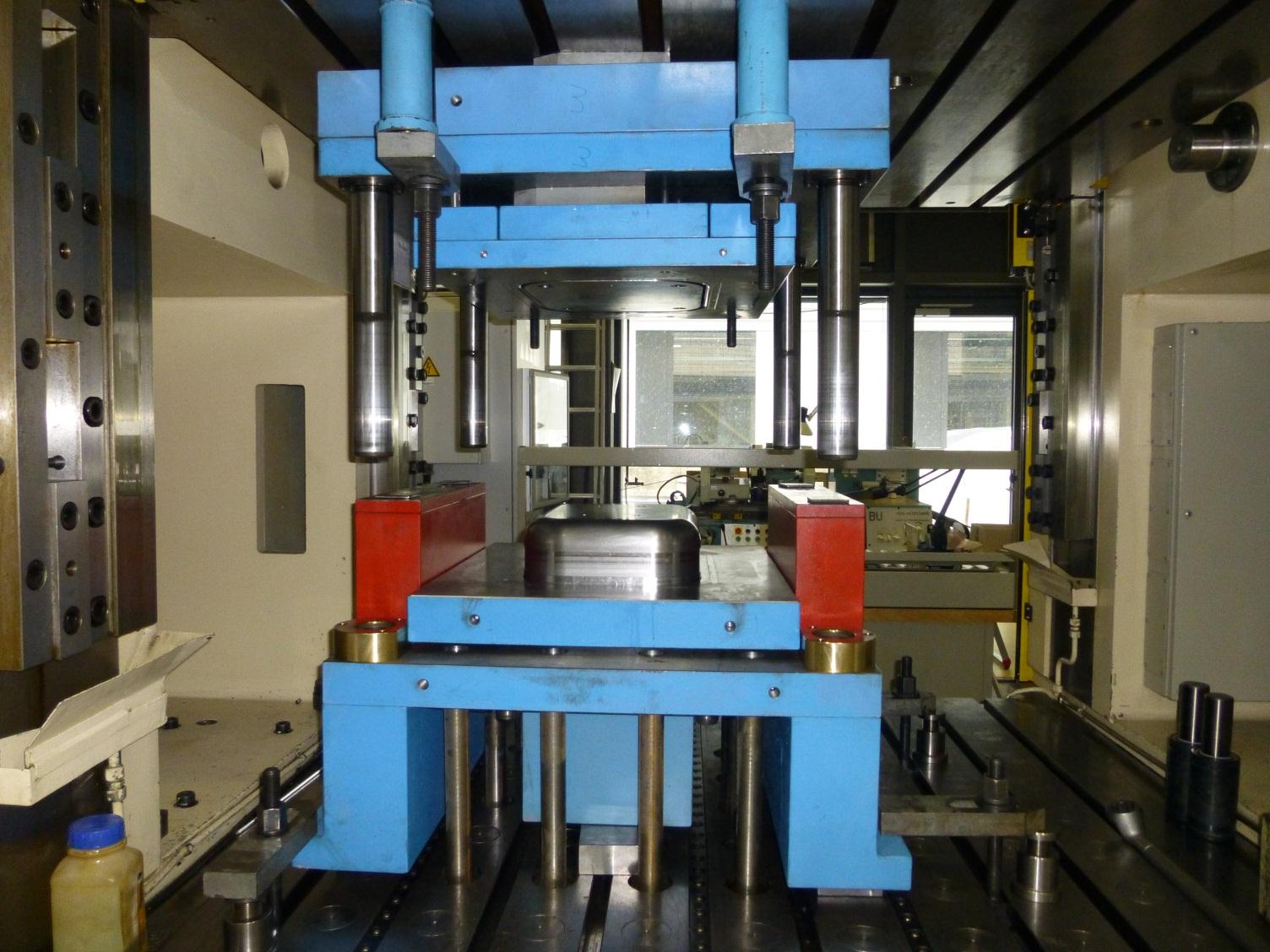

Forming of composite parts |

||

|---|---|---|

|

Example tool for deep drawing

|

|

Publications

Reviewed publications

| [Tro16] | Troge J, Drossel W-G, Lochmahr M, Zumach S (2016) Reducing rear axle gear whine noise inside a car by influencing the structure-borne sound transfer path using structurally integrated piezo-actuators. In: Miyara, Federico ; Asociación de Acústicos Argentinos -AdAA-: 22nd International Congress on Acoustics, ICA 2016. Proceedings : Buenos Aires, 5 to 9 September, 2016 |

| [Dro06] | Drossel W-G (2006) Adaptronik Anwendungen. In: Schirmer W (Hrsg) Technischer Lärmschutz, Grundlagen und praktische Maßnahmen zum Schutz vor Lärm und Schwingungen von Maschinen. Springer, Berlin, S 426-444 |

| [Neu10a] | Neugebauer R, Lachmann L, Drossel W-G, Nestler M, Hensel S (2010) Multi-layer compounds with integrated actor-sensor-functionality. Prod Eng Res Devel 4(4):379-384 |

| [Neu13] | Neugebauer R, Lachmann L, Drossel W-G, Nestler M, Hensel S (2013) Smart Semi-Finished Parts for the Application in Sheet-Metal Structures. In: Schuh G et al. (eds) Future trends in production engineering, Berlin, Germany, pp 121-130 |

| [Dro13] | Drossel W-G, Hensel S, Nestler M, Lachmann L (2013) Evaluation of Actuator, Sensor and Fatigue Performance of Piezo-Metal-Composites. IEEE Sens J, doi:10.1109/JSEN.2013.2296143) |

| [Dro14] | Drossel W-G, Hensel S, Nestler M, Lachmann L, Schubert A, Müller M, Müller B (2014) Experimental and numerical study on shaping of aluminum sheets with integrated piezoceramic fibers. In: J Mater Process Technol 214(2):217-228 |

| [Neu10c] | Neugebauer R, Drossel W-G, Pagel K, Kranz B (2010) Making of state space models of piezomechanical systems with exact impedance mapping and strain output signals. In: Proc 12th Mechatron Forum Biennal Int Conf, vol 2, pp 73-80 |

Andere Veröffentlichungen

| [Neu10b] | Neugebauer R, Drossel W-G, Lachmann L, Hensel S, Nestler M (2010) Experimental and Numerical Study on efficient Forming Operations of Sheet-Metal-Compounds with Integrated Piezo- Modules. In: Steel Res Int, Metal Forming 81(9):725-728 |

| [Neu12] | Neugebauer R, Drossel W-G, Lachmann L, Nestler M, Hensel S (2012) Actuator and Sensor Performance of Piezo-Metal-Composites. In: IEEE Sens Proc. Taiwan, pp 355-358 |

Contact

Project Manager:Prof. Dr.-Ing. Welf-Guntram Drossel

Fraunhofer-Institut für Werkzeugmaschinen und Umformtechnik IWU

Reichenhainer Straße 88

09126 Chemnitz

E-Mail: welf-guntram.drossel@…

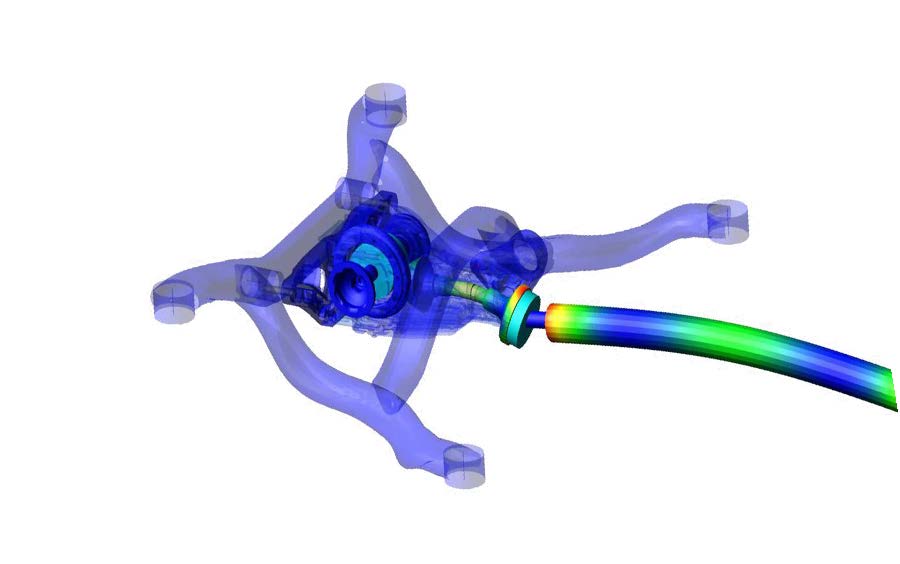

Simulation model of a rear axle assembly

Simulation model of a rear axle assembly