Materialcharakterisierung und numerische Simulation von adaptiven Werkstoffverbunden

R. Lerch, S. J. Rupitsch

Aims

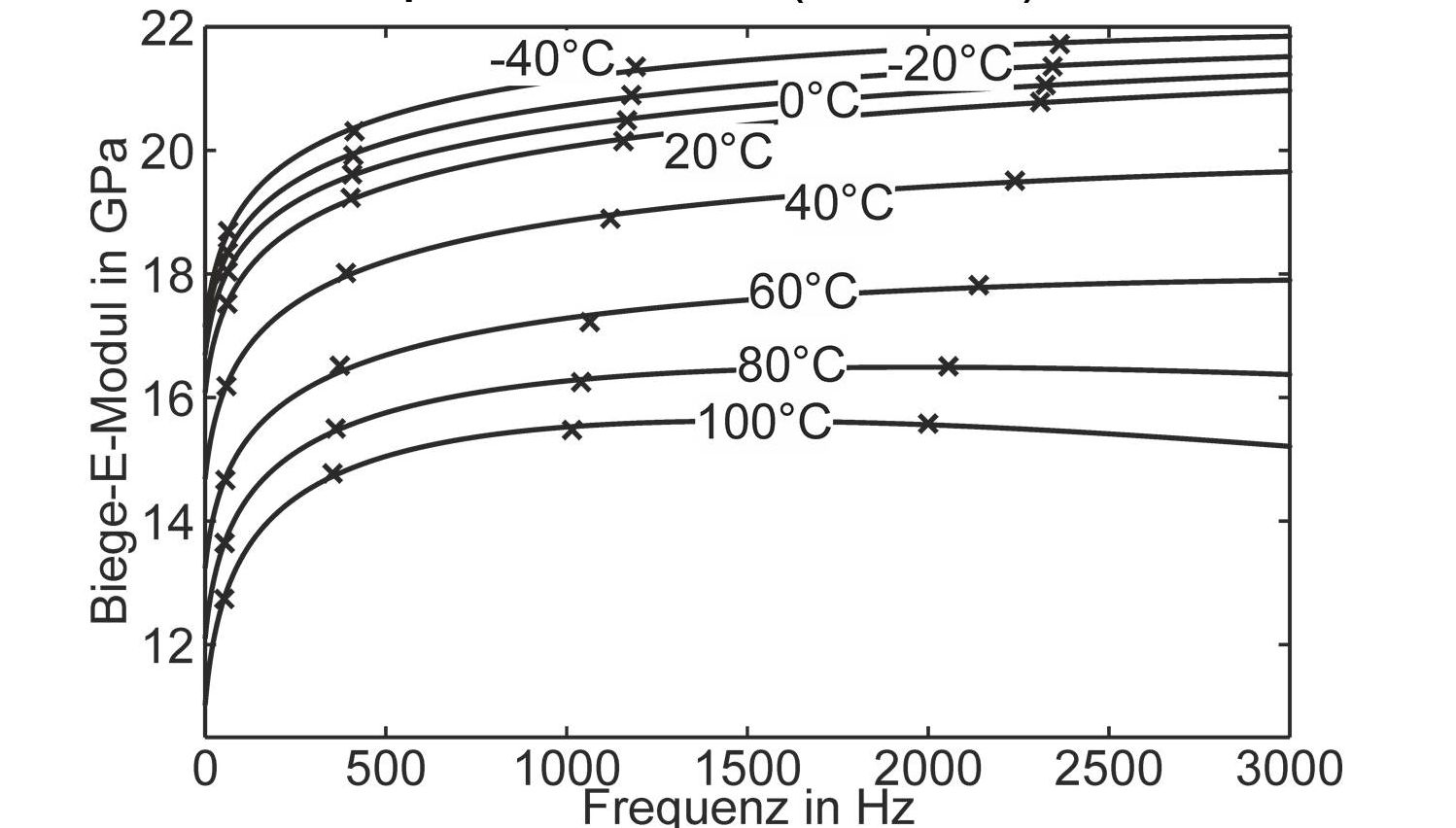

Characterization of all materials involved in compound

- Parameter catalog of active and passive materials

- Consideration of various influences

- Frequency

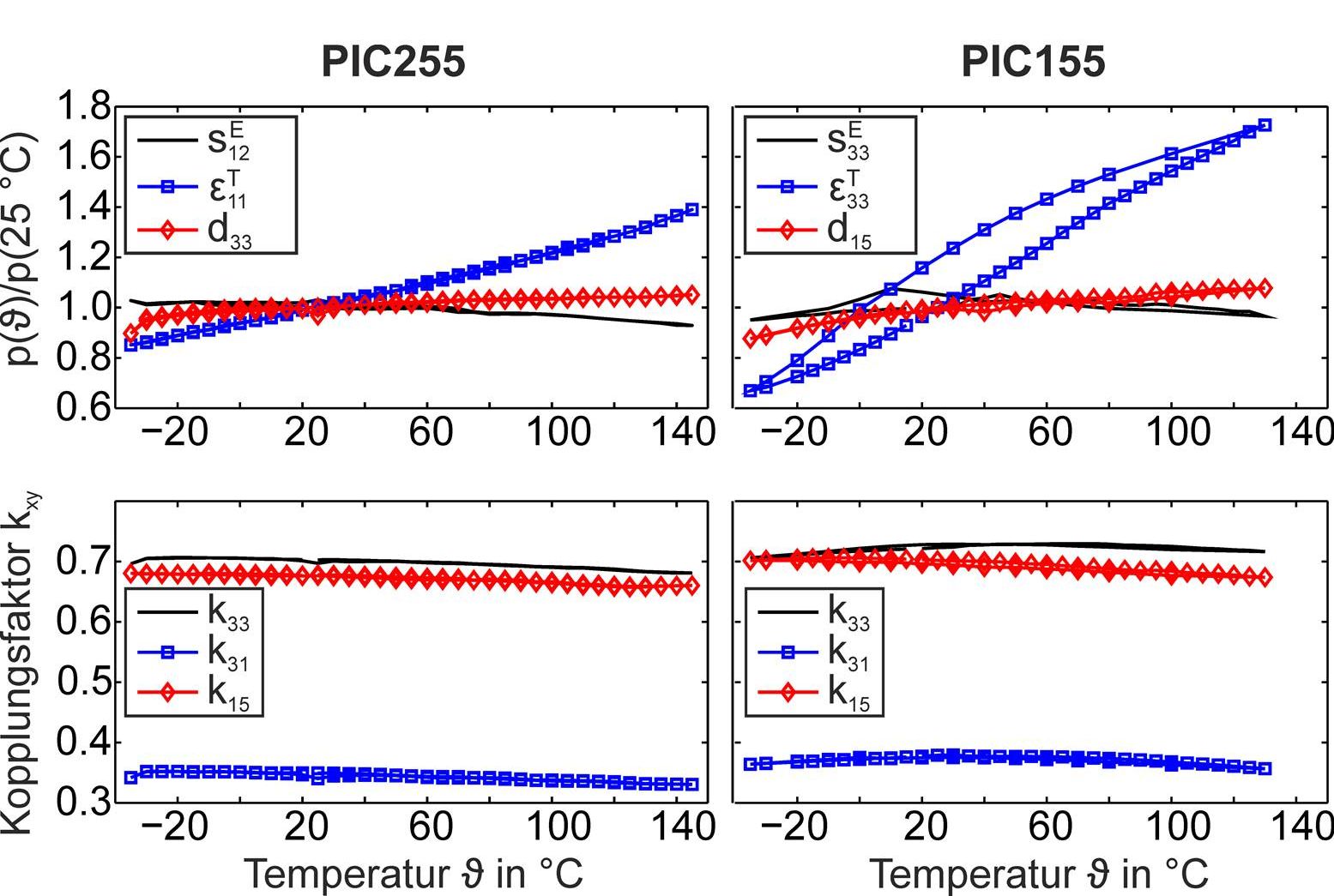

- Temperature

- Mechanical prestress

- Continuous load

Simulation platform for functional system design

- Based on finite element simulations

- Consideration of excitation and analysis electronics

- Applications of adaptive compounds

- Structural health monitoring

- Energy harvesting

- ….

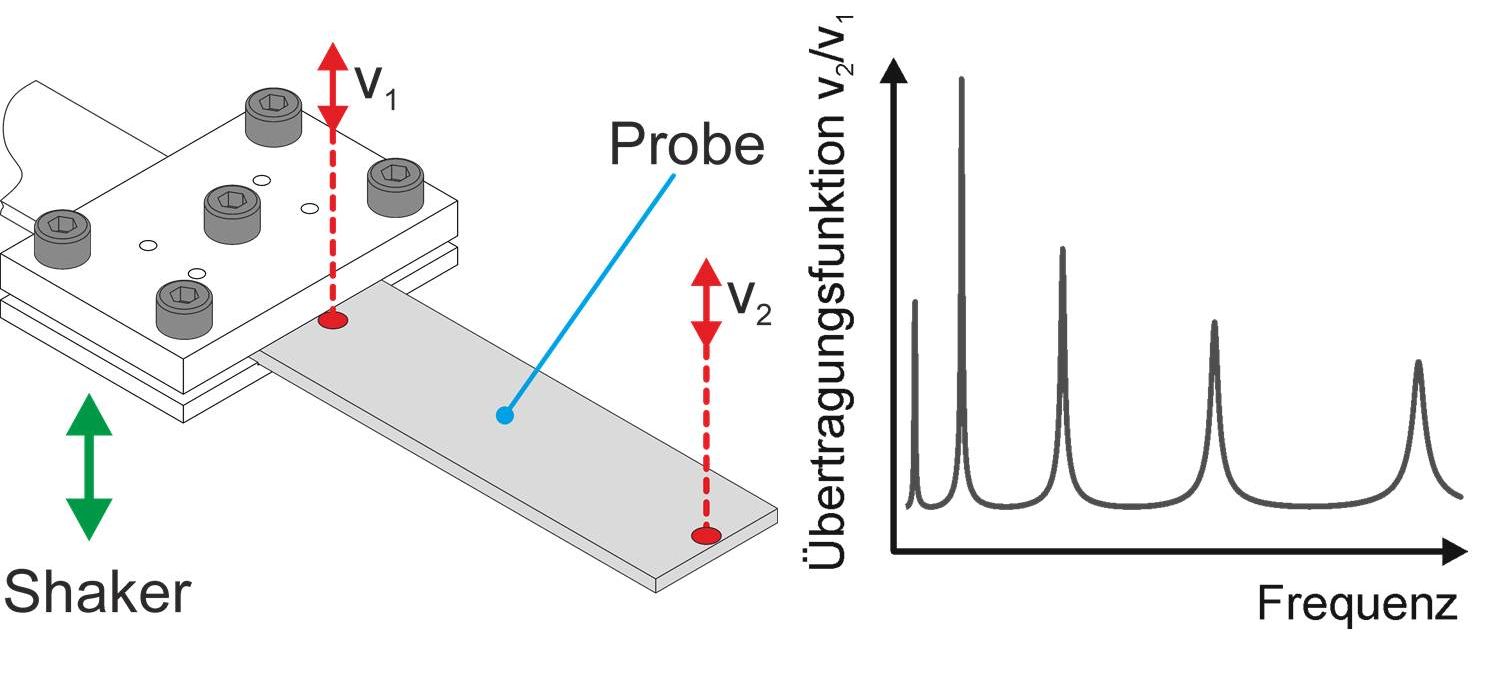

Functional control of adaptive material compounds during production

- Use of as less characteristic measurands as possible

- Electrical impedance

- Mechanical displacement

- Design of inspection guidelines

Results

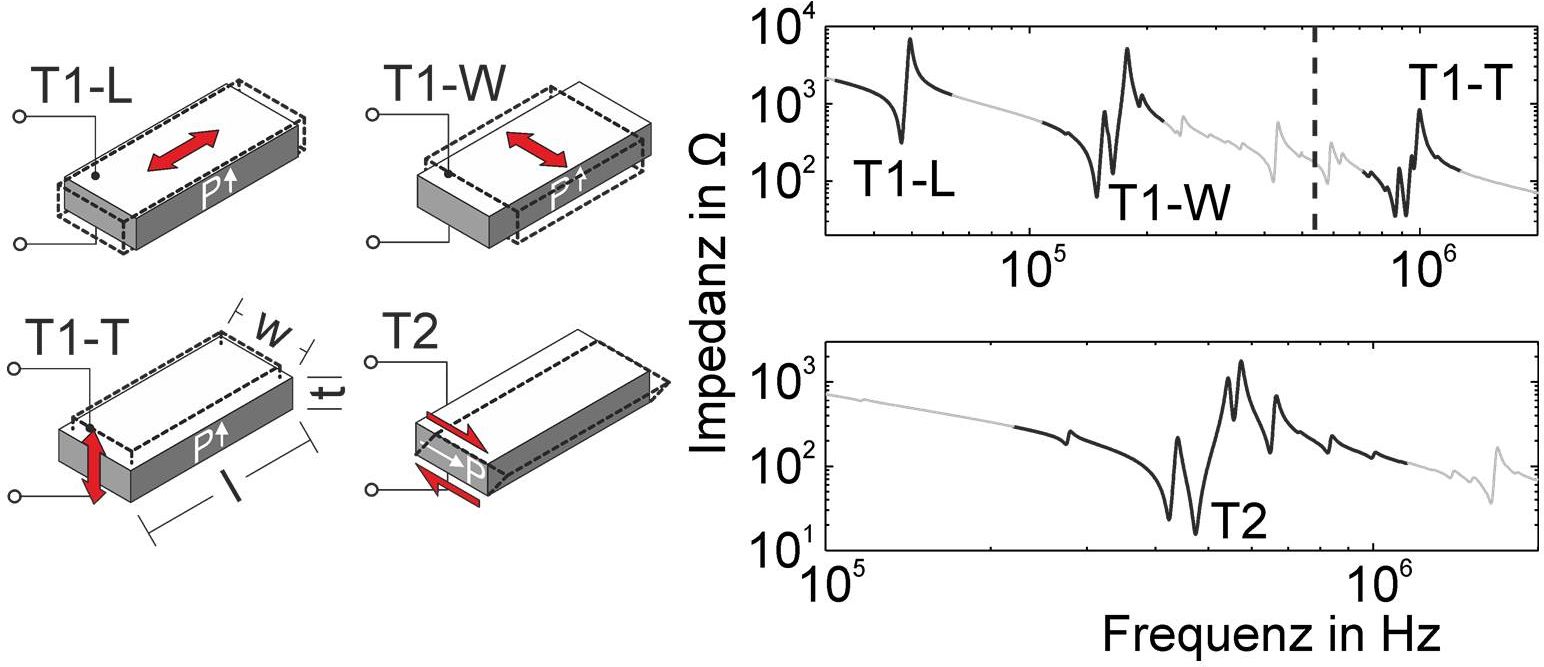

Piezoceramics

|

Passive materials

|

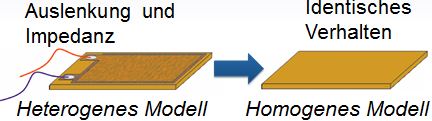

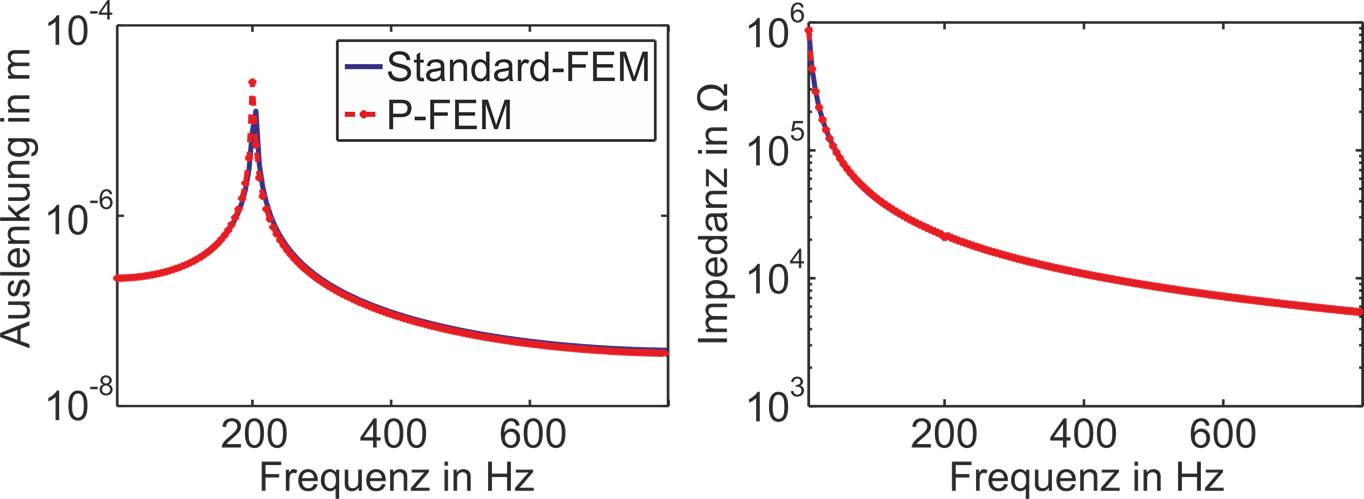

Efficient Modelling

|

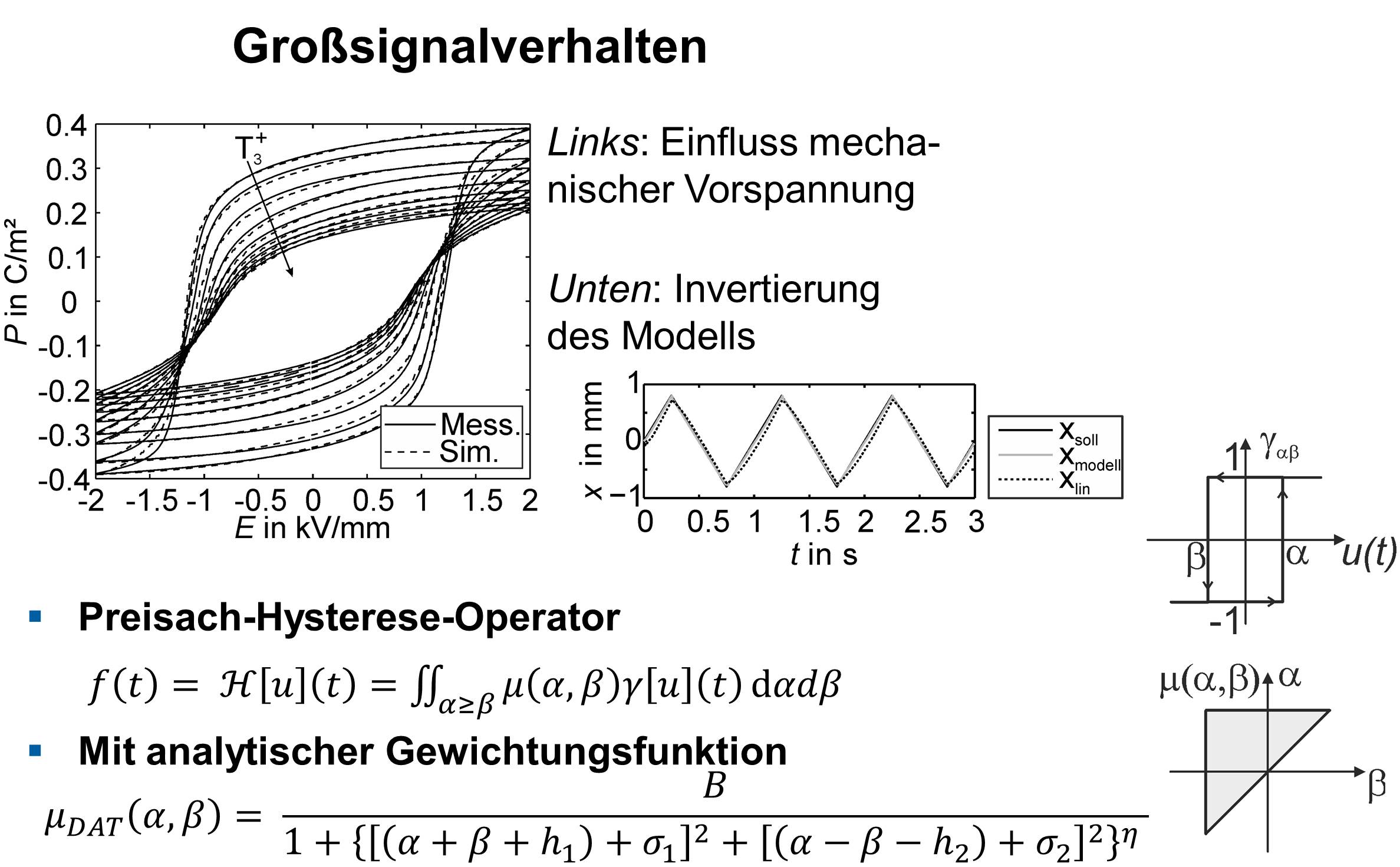

Large Signal Performance

|

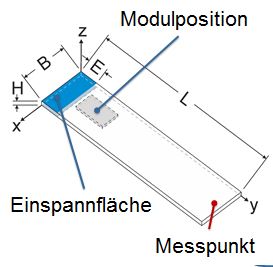

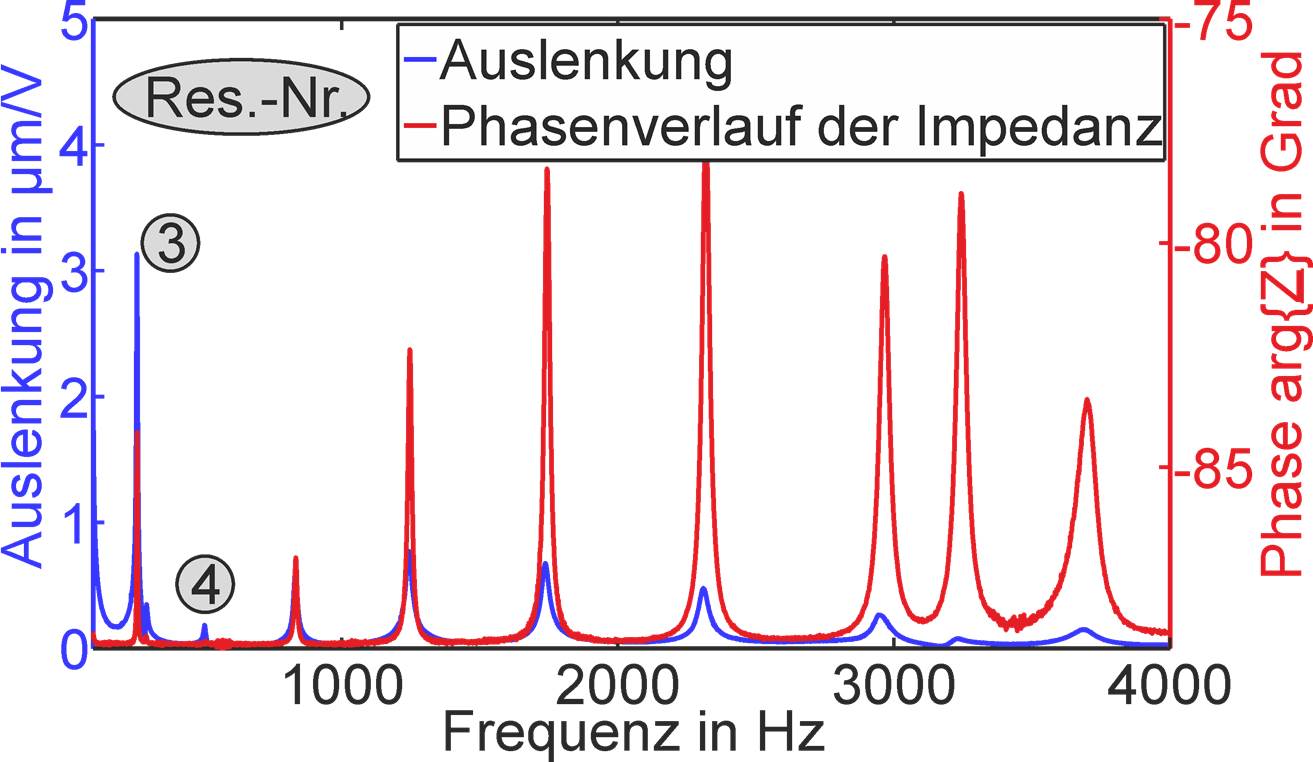

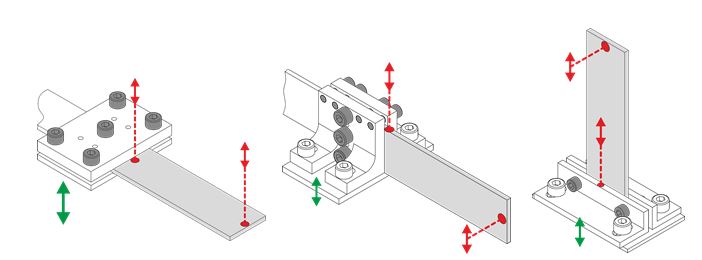

PT-PIESA-Standard Panels

- Uniform measurement enviroment

- Measurement von impendace, deflection, force Messung von Impedanz, Auslenkung, Kraft

- Example: GF-PA6 (TP B04)

|

|

Methods

|

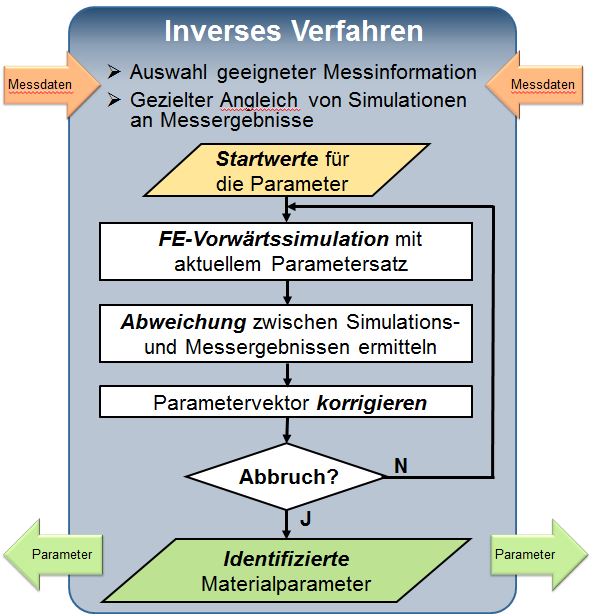

Inverse Method |

|

|---|---|

|

|

Finite element simulation |

|

|---|---|

|

| Measurement |

|---|

|

Publications

Reviewed Publications

| [Sut10] | Sutor A, Rupitsch SJ, Lerch R (2010) A Preisach-based hysteresis model for magnetic and ferroelectric hysteresis. Appl Phys A 100:425-430 |

| [Wol11] | Wolf F, Sutor A, Rupitsch S J, Lerch R (2011) Modeling and measurement of creep- and rate-dependent hysteresis in ferroelectric actuators. Sens Actuators A 172(1):245-252 |

| [Kla12] | Klassen A, Rübner M, Ilg J, Rupitsch SJ, Lerch R, Körner C, Singer RF (2012) Influence of the fabrication process on the functionality of piezoceramic patch transducers embedded in aluminum die castings. Smart Mater and Struct 21(11):115014(11pp) |

| [Rup12] | Rupitsch SJ, Wolf F, Sutor A, Lerch R (2012) Reliable modeling of piezoceramic materials utilized in sensors and actuators. Acta Mech 223(8):1809-1821 |

| [Wol12] | Wolf F, Sutor A, Rupitsch SJ, Lerch R (2012) A generalized Preisach approach for piezoceramic materials incorporating uniaxial compressive stress. Sens Actuators A 186:223-229 |

| [Ilg13] | Ilg J, Rupitsch SJ, Lerch R (2013) Impedance based temperature sensing with piezoceramic devices. IEEE Sens J 13(6):2442-2449 |

| [Huf14] | Hufenbach WA, Modler N, Winkler A, Ilg J, Rupitsch SJ (2014) Fibre-reinforced composite structures based on thermoplastic matrices with embedded piezoceramic modules. Smart Mater Struct 23(2):25011(10pp) |

Other Publications

| [Rup10] | Rupitsch SJ, Sutor A, Ilg J, Lerch R (2010) Identifcation procedure for real and imaginary material parameters of piezoceramic materials. In: IEEE IUS, pp 1214-1217 |

| [Rup11a] | Rupitsch SJ, Ilg J, Sutor A, Lerch R (2011) Variation of material parameters for the thickness extensional mode of piezoceramic discs in case of mechanical loading. Proc Eng 25:1441-1444 |

| [Rup11b] | Rupitsch SJ, Ilg J, Lerch R (2011) Enhancement of the Inverse Method enabling the material parameter identification for piezoceramics. In: IEEE IUS, pp 357-360 |

| [Rup13] | Rupitsch SJ, Ilg J, Lerch R (2013) Inverse scheme to identify the temperature dependence of electromechanical coupling factors for piezoceramics. In: IEEE Int Symp Appl Ferroelectr, pp 183-186 |

| [Wol13] | Wolf F, Hirsch H, Sutor A, Rupitsch SJ, Lerch R (2013) Efficient compensation of nonlinear transfer characteristics for piezoceramic actuators. In: IEEE Int Symp Appl Ferroelectr, pp 171-174 |

Contact

Project Manager:Prof. Dr.-Ing. Reinhard Lerch

Friedrich-Alexander-Universität Erlangen-Nürnberg

Lehrstuhl für Sensorik

Paul-Gordan-Str. 3/5

91052 Erlangen

E-Mail: reinhard.lerch@…

Dr. techn. Stefan Johann Rupitsch

Friedrich-Alexander-Universität Erlangen-Nürnberg

Lehrstuhl für Sensorik

Paul-Gordan-Str. 3/5

91052 Erlangen

E-Mail: stefan.rupitsch@…