Production technologies of piezo-modules with integrated ceramic composites and functional polymers for application in active metallic components

L. Kroll, J. Tröltzsch

Objectives

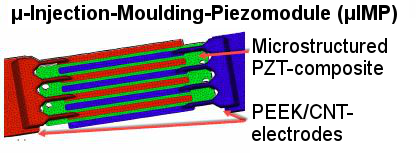

Production of µIMP-modules with adjusted preload of the piezo-ceramic as well as material immanent electromechanical functions based on thermoplastic piezo-ceramic composites for integration in metallic (A03) and plastic-based lightweight structures (T02) in large-scale production

- Fully automated fabrication of discrete µIM-piezo modules

- Variation of the material for thermoplastic piezo-ceramic composites for a robust processing by micro injection molding

- Specifically adjustment of process-related internal compressive stresses for optimal electromechanical properties in the µIMP

- Material modification for optimized polarization

Results

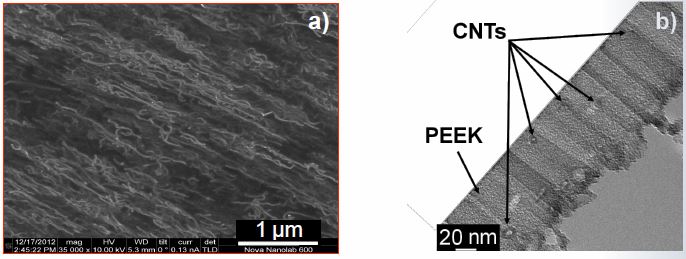

Morphology of CNTs in micro injection molded test samples of PEEK

- Orientation of the CNTs due to process-related near-surface shear zone

→ Directionality of electrical conductivity - Homogeneous distribution of CNTs with distinct network structure and without development of agglomerates

→ Percolation threshold at small percentages of CNTs - Very high proportion of CNTs at the surface of the micro injection molded test samples

→ Small electrical contact resistance

→ Slightly pronounced parasitic capacity

b) TEM micrograph of a partial cross-section perpendicular to the flow direction of the melt

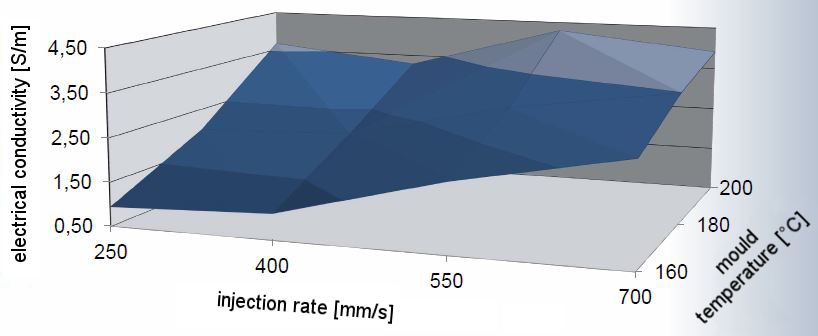

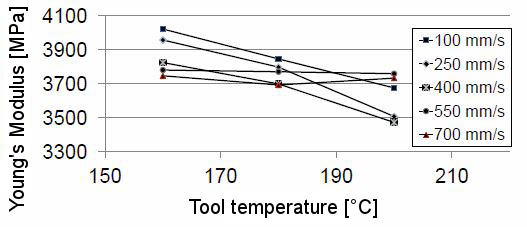

Investigation of process-related electrical conductivities at PEEK-CNT- nanocomposite structures

- High conductivity due to short filling process time

→ Optimal injection velocity at 550 mm/s - Large proportion of CNTs at the structural surface with increasing mold temperature

→ Formation of the shear zone close to cavity - Sufficient electrical conductivity already at 7 wt.% CNT for forwarding of small signals

→ Processability of nanocomposites by injection molding technologies

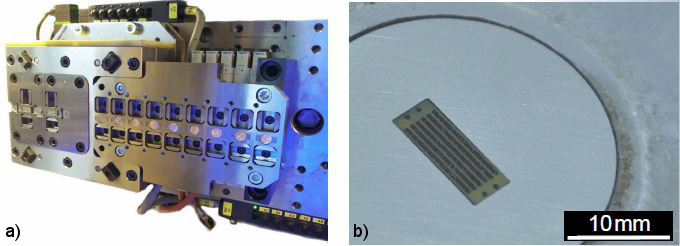

Micro injection molding process evaluation with µIMP-tool

- Newly gripper-concept with highly tempered mounting for micro structured piezo-ceramics

→ TPZT = 180°C at mold transfer with ± 5 µm positional tolerance - Proof of low internal stress µIMP in compact constructions

- Defined internal compressive stresses in PZT (10 to 30 MPa) by specific adjustment of the process parameters

→ Convenient electromechanical performance

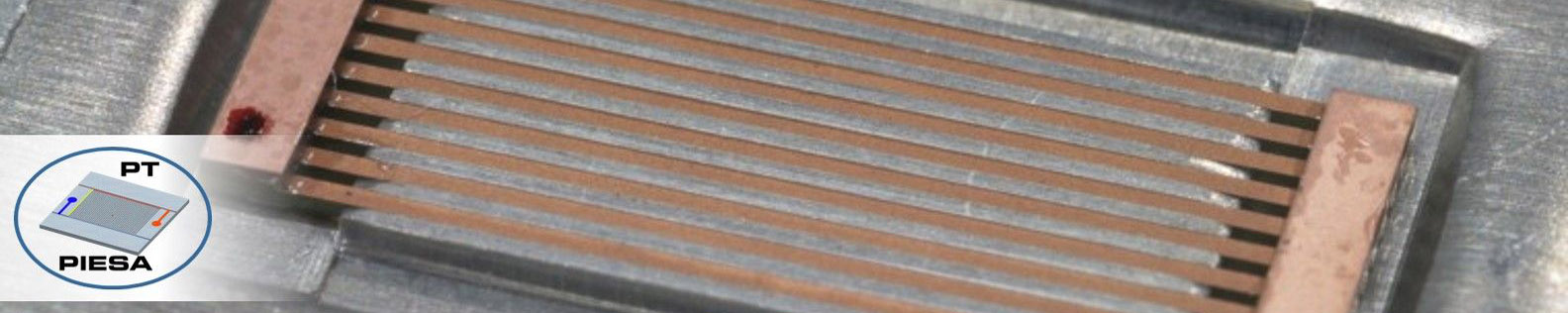

a) µIMP micro injection molding tool; b) µIMP embedded in aluminum

Methods

|

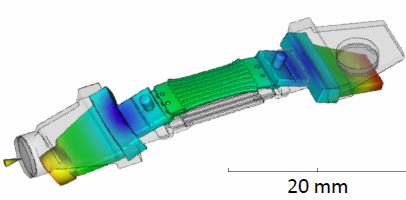

Tool and process simulation |

|

|---|---|

|

Thermo mechanical deformation analysis

(Scaling factor: 10; red: max. 0.5 mm; green: 0.3 mm) |

| Production studies, sensitivity analysis | |

|---|---|

|

Young’s modulus of PEEK filled with 7 wt.% CNT as a function of tool temperature and injection rate

|

| µIMP-conditioning | |

|---|---|

|

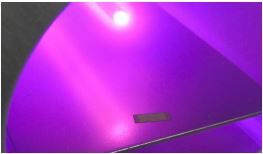

Surface activation of micro structured PZT in plasma atmosphere

|

Publications

Reviewed Publications

| [Gra16] | Graf A, Kräusel V, Landgrebe D, Decker R, Kroll L (2016) Joining and forming of hybrid assembled composites with sensory function. Euro Hybrid Materials and Structures 2016. ISSN: 978-3-88355-414-3 |

| [Dec15] | Decker R, Heinrich M, Tröltzsch J, Kroll L (2015) Fertigungstechnologien für Piezomodule mit integrierten Keramikkompositen und Funktionspolymeren zum Einsatz in aktiven metallischen Bauteilen. Forum Spritzgießen: Funktionsintegration - Innovationen im Kunststoffbauteil, 2015. |

| [Dec15] | Decker R, Heinrich M, Tröltzsch J, Rhein S, Gebhardt S, Michaelis A, Kroll L (2015) Development and characterization of piezo-active polypropylene compounds filled with PZT and CNT In: Proceedings 5th Scientific Symposium CRC/Transregio 39, pp. 59-64, 2015. |

| [Fis13] | Fischer T, Wetzold N, Kroll L, Hübler AC (2013) Flexographic Printed Carbon Nanotubes on Polycarbonate Films - Yielding High Heating Rates. J Appl Polym Sci 1:1-9 |

| [Hei15] | Heinrich M, Decker R, Schaufuß J, Tröltzsch J, Mehner J, Kroll L (2015) Electrical contact properties of micro-injection molded Polypropylene/CNT/CB-composites on metallic electrodes In: Advanced Material Research, 1103: pp. 77-83, 2015. DOI: http://www.scientific.net/AMR.1103.77 |

| [Hei12a] |

Heinrich M, Sichting F, Kroll L (2012) |

| [Krä15] | Kräusel V, Graf A, Heinrich M, Decker R, Caspar M, Kroll L, Hardt W, Göschel A (2015) Development of hybrid assembled composites with sensory function In: CIRP Annals - Manufacturing Technology, 64(1), 2015. DOI: 10.1016/j.cirp.2015.04.054 |

| [Kro11] | Kroll L, Nendel W, Heinrich M, Stelzer R, Tröltzsch J, Walther M (2011) Bewertung prozessbedingter Eigenspannungen von mikrospritzgießverarbeiteten piezoaktiven Hybridmodulen. J Plast Technol 1:17-43 |

| [Nie13] | Niedziela D, Tröltzsch J, Latz A, Kroll L (2013) On the numerical simulation of injection molding processes with integrated textile fiber reinforcements. J Thermoplast Compos Mater 26(1):74-90 |

| [Sch13] | Schulze R, Heinrich M, Nossol P, Forke R, Sborikas M, Tsapkolenko A, Billep D, Wegener M, Kroll L, Gessner T (2013) Piezoelectric P(VDF-TrFE) transducers assembled with micro injection molded polymers. Sens Actuators A: Phys, doi:10.1016/j.sna.2013.12.032 |

| [Trö10] | Tröltzsch J, Kroll L (2010) Investigation of polymer melt impregnated fibre tapes in injection moulding process. In: Integr Syst Des Technol. Springer, Berlin, pp 67-78 |

| [Ulk13] | Ulke-Winter L, Klärner M, Kroll L (2013) Determining the damping behavior of fiber reinforced composites - A new approach to find mathematical relationships in data sets. Compos Struct 100:34-39 |

| [Wal10] | Walther M, Nendel W, Heinrich M, Klärner M, Tröltzsch J, Kroll L (2010) Initial stress behaviour of micro injection-moulded devices with integrated piezo-fibre composites. In: Integr Syst Des Technol. Springer, Berlin, pp 109-120 |

Andere Veröffentlichungen

| [Kro13] | Kroll L, Heinrich M, Nendel W (2013) Electrical and mechanical behavior of PEEK nano composites based on carbon nano tubes. In: Proc CRC/Transregio 39. Nuremberg, Germany, pp 49-52 |

| [Mül13] | Müller M, Peter S, Berg S, Heinrich M, Walther M, Hohlfeld K, Heberle J, Quentin U, Koriath H-J, Gebhardt S, Schmidt M, Michaelis A, Kroll L, Richter F, Neugebauer R (2013) Microstructured Piezoceramic and Fibre Composite Transducers for Active Semi-Finished Products. In: Proc CRC/Transregio 39. Nuremberg, Germany, pp 25-31 |

| [Hei12b] | Heinrich M, Kroll L, Sichting F (2012) Process-related mechanical properties of conductive Nanocomposites based on CNT-filled Polypropylen. In: Proc NanoSpain Conf. Santander, Spain |

Patente

| [Fra11] | Fraunhofer Gesellschaft zur Förderung der angewandten Forschung e.V. Piezoelektrisches Funktionsmodul und Verfahren zur Herstellung. Patentanmeldung WO002011038703A1. 2011-04-07 |

| [Tec09] | [Tec09] Technische Universität Chemnitz. Sensormodul, Verfahren zum Herstellen eines Sensormoduls sowie Signalerfassungs- und Verarbeitungsverfahren. Offenlegungsschrift DE102007056409A1. 2009-05-28 |

Contact

Project Manager:Univ.-Prof. Dr.-Ing. habil. Lothar Kroll

Chemnitz University of Technology

Institut für Allgemeinen Maschinenbau und Kunststofftechnik

Professur Strukturleichtbau und Kunststoffverarbeitung

09107 Chemnitz

E-Mail: lothar.kroll@…

Dr.-Ing. Jürgen Tröltzsch

Chemnitz University of Technology

Institut für Allgemeinen Maschinenbau und Kunststofftechnik

Professur Strukturleichtbau und Kunststoffverarbeitung

09107 Chemnitz

E-Mail: juergen.troeltzsch@…