Shaping of Piezo-Metal-Compounds and Numerical Studies of Forming and Functionality

W.-G. Drossel, R. Müller

Aims

The objective of subproject B01 is the development of a serial production capable technology for the fabrication of shaped sandwich components with an integrated sensor and actuator functionality.

Results

Achivements

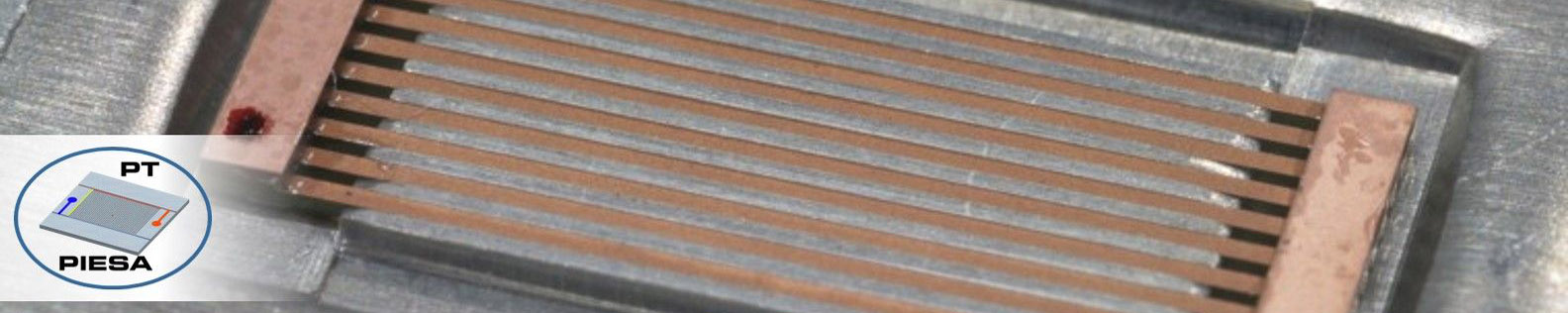

In earlier studies it was shown that forming of a compound with highly brittle piezoceramic fibers is possible. Therefore during the forming process a relative movement between piezomodule and the sheet metals is ensured using a viscous adhesive.

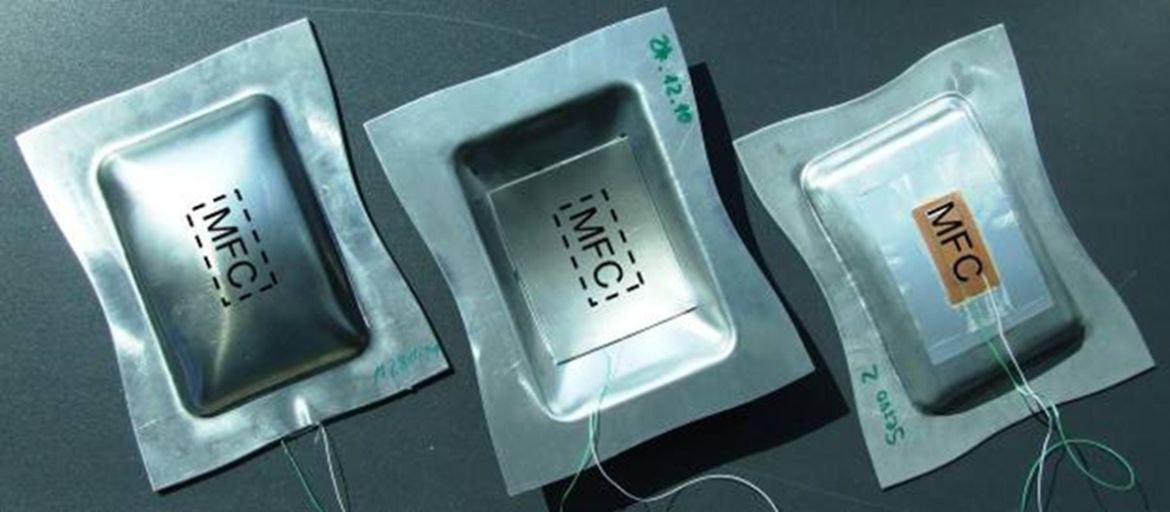

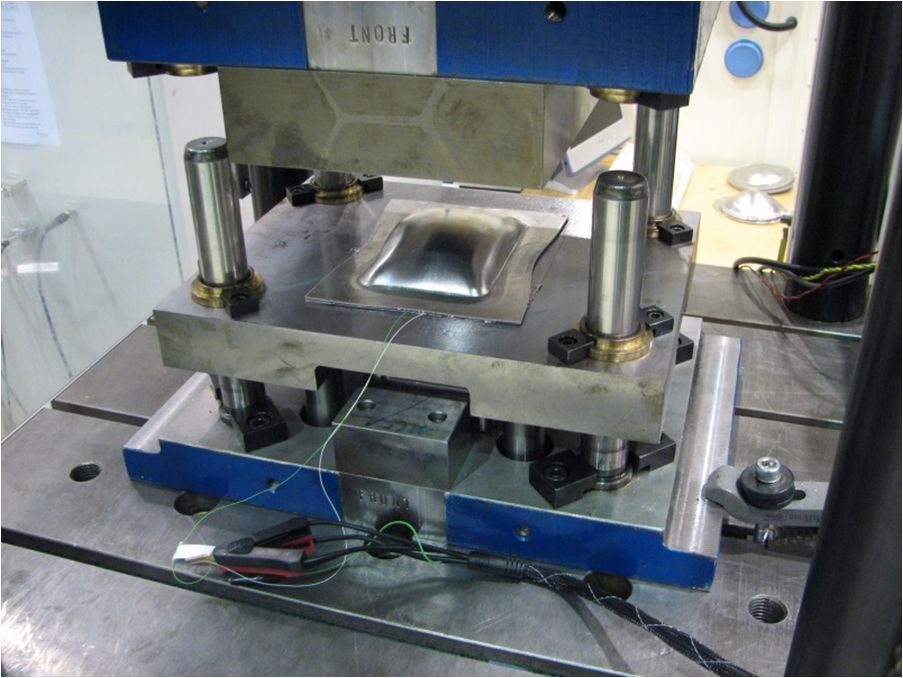

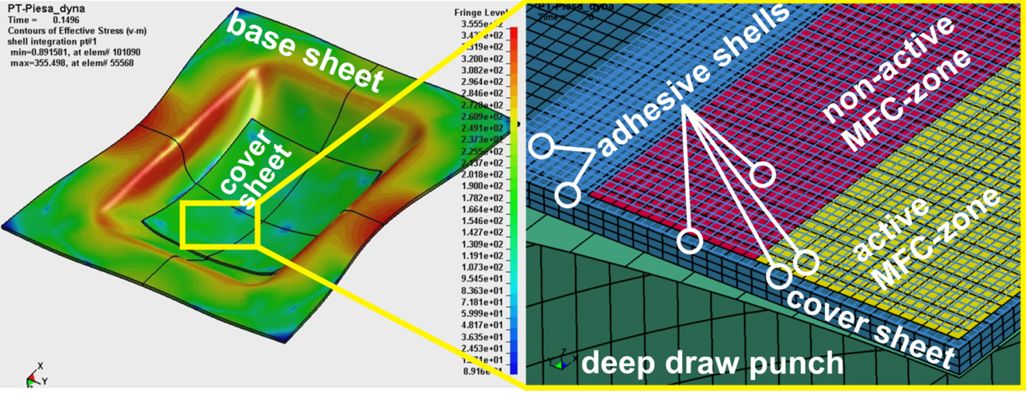

With variation of the sandwich design, compounds with local and global cover sheets were produced. Bending test, deep drawing test and stretch drawing test were carried out to investigate several load cases for the piezomodule. Through various test methods (X-Ray, capacity test, investigation of the sensor and actuator functionality) the forming limits were identified and the functionality of the piezo-metal-compounds was characterized. In addition to the experiments numerical simulations of the forming processes were performed. Focus of the simulation is the description of the piezomodule loads resulting from the forming process and the prediction of the piezomodule functionality using a developed degradation model.

In order to show the potentials of the process chain, exemplary structural parts for active vibration control and health-monitoring were developed.

In collaboration with the subprojects A02 and A03 forming tests of micro-structured piezo-metal- compounds were realized. Additionally numerical studies for micro-structuring, joining by forming and deep-drawing of micro-structured piezo-metal-compounds were performed in close connection to experimental tests.

Figure 1: Rectangular cup with global and local cover sheet

Figure 2: Deep-drawing tool for fabrication of rectangular cups

Figure 3: Simulation model for forming of piezo-metal- compounds

Figure 4: Microsection of a bending sample with a bending radius of 10 mm

Figure 5: Functional demonstrator for the monitoring of a bolted joint (health-monitoring) using integrated piezomodules

Figure 6: Forming and simulation of micro-structured piezo-metal-compounds (cooperation with TP A02/A03)

Methods

|

The main approach for the fabrication of piezo-metal-compounds is the integration of planar piezomodules between basic sheets and cover-layers using a liquid adhesive and the shaping of structural parts. The forming process is performed when the adhesive is in a viscous condition, and thus the tensile loads in the piezo-module are significantly reduced. In order to achieve a good sensor and actuator functionality, a stiff connection of piezo-module and sheet metals is realized through the hardening of the adhesive after forming. The following methods are used in this subproject:

|

Publications

Reviewed Publications

| [1] | Neugebauer R, Lachmann L, Drossel W-G, Nestler M, Hensel S (2010) Multi-layer compounds with integrated actor-sensor-functionality. Prod Eng, Special Issue, pp 379-384 |

| [2] | Neugebauer, R.; Lachmann, L.; Drossel, W.-G.; Hensel, S.; Kranz, B.; Nestler, M.: Piezo-Metal-Composites as Smart Structures. Proceedings of the 36th International MATADOR Conference, 2010, S. 175-178 |

| [3] | Neugebauer, R.; Drossel, W.-G.; Lachmann, L.; Hensel, S.; Nestler, M.: Experimental and Numerical Study on efficient Forming Operations of Sheet-Metal-Compounds with Integrated Piezo-Modules. Steel Research International, Metal Forming 2010, Volume 81, Number 9, September 2010; S. 725-728 |

| [4] | Neugebauer, R.; Lachmann, L.; Drossel, Welf-G.; Nestler, M.; Hensel, S.: Smart Semi-Finished Parts for the Application in Sheet-Metal Structures. Future trends in production engineering: Proceedings of the WGP Conference, Berlin, 2013, S.121-130 (DOI: http://dx.doi.org/10.1007/978-3-642-24491-9_13) |

| [5] | Suchanek, G.; Eydam, A.; Hu, W.; Kranz, B.; Drossel, W.-G.; Gerlach, G.: Evaluation of Polarization of Embedded Piezoelectrics by the Thermal Wave Method. IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control, Vol. 59, No. 9, 2012, S. 1950-1954 |

| [6] | Drossel, W.-G.; Hensel, S.; Nestler, M.; Lachmann, L.; Schubert, A.; Müller, M.; Müller, B.: Experimental and numerical study of production methods for shaped metal sheets with micro-formed piezo-metal substructures: Journal of Materials and Processing Technology, Vol. 214, 2013, S. 217-228 |

| [7] | Drossel, W.-G.; Hensel, S.; Nestler, M.; Lachmann, L.: Evaluation of Actuator, Sensor and Fatigue Performance of Piezo-Metal-Composites, IEEE SENSORS JOURNAL, VOL. 14, NO. 7, JULY 2014, S. 2129-2137 |

| [8] | Hensel, S.; Drossel, W.-G.; Nestler, M.; Müller, R.: Modeling of the performance reduction of Macro Fiber Composites for use in numerical forming simulation of piezoceramic-metal-compounds. CIRP Journal of Manufacturing Science and Technology, Vol. 7, 2014, S. 124-138 |

| [9] | Nestler, M.; Drossel, W.-G.; Hensel, S.; Müller, R.: Fabrication method for series production of sheet metal parts with integrated piezoelectric transducers. Procedia Technology 15, 2014, S. 494 – 502 |

| [10] | Müller, M.; Müller, B.; Hensel, S.; Nestler, M.; Jahn, S. F.; Wittstock, V.; Schubert, A.; Drossel, W.-G.: Structural integration of PZT fibers in deep drawn sheet metal for material-integrated sensing and actuation. Procedia Technology 15, 2014, S. 659 – 668 |

| [11] |

Müller, M.; Müller, B; Hensel, S.; Nestler, M.; Jahn, S. F.; Müller, R.;Schubert, A.; Drossel, W.-G.:

Structural integration of piezoceramic fibers indeep drawn sheet metal for material-integrated health monitoring. Mechatronics,Available online 20 October 2015 (DOI:http://dx.doi.org/10.1016/j.mechatronics.2015.09.006)

|

Not Reviewed Publications

| [1] | Neugebauer, R.; Ihlemann, J.; Lachmann, L.; Drossel, W.-G.; Hensel, S.; Nestler, M.; Landgraf, R.; Rudolph, M.: Piezo-Metal-Composites in Structural Parts: Technological Design, Process Simulation and Material Modelling. 3. Wissenschaftliches Symposium PT-Piesa, Oktober 2011, S. 51-56 |

| [2] | Neugebauer, R.; Lachmann, L.; Nestler, M.: Herausforderungen bei der Umformung von Piezo-Metall-Verbunden. Verformungskundliches Kolloquium Leoben, Februar 2012 |

| [3] | Neugebauer, R.; Drossel, W.-G.; Lachmann, L.; Nestler, M.; Hensel, S.: Actuator and Sensor Performance of Piezo-Metal-Composites. IEEE Sensors Proceedings, Taiwan, 2012, S. 355-358, ISBN: 978-1-4577-1765-9 |

| [4] | Neugebauer, R.; Drossel, W.-G.; Lachmann, L.; Nestler, M.; Hensel, S.: Funktionsintegration in Strukturbauteilen. Conference Proceedings 4. ICAFT / 19. SFU 2012, Berichte aus Quelle dem IWU, Band 66, Oktober 2012, S. 209-226 |

| [5] | Neugebauer, R.; Ihlemann, J.; Lachmann, L.; Drossel, W.-G.; Hensel, S.; Nestler, M.; Rudolph, M.: Experiments and FE-Simulation of the forming and curing process of bonded Piezo-Metal-Structures. 4. Wissenschaftliches Symposium PT-Piesa, März 2013, S. 103-108 |

| [6] | Neugebauer, R.; Schubert, A.; Drossel, W.-G.; Lachmann, L.; Koriath, H.-J.; Jahn, S. F.; Nestler, M.; Hensel, S.; Müller, M.; Müller, B.: Deep Drawing of Metal Sheets with Integrated Piezo-Metal Substructures; 4. Wissenschaftliches Symposium PT-Piesa, März 2013, S. 37-42 |

| [7] | Drossel, W.-G.; Hensel, S.; Nestler, M.; Lachmann, L.: Shaping of piezo-metal-composites. International innovation (2013), No.117, S. 91, ISSN: 2041-4552 |

| [8] | DDrossel, W.-G.; Schubert, A.; Nestler, M.; Hensel, S.; Müller, R.; Müller, M.; Müller, B; Jahn, S. F.: Novel sheet metal parts with sensor and actuator mode of operation. In Forming with Intelligence, Flexibility and Lightweight, Proceedings of the 34th International Deep Drawing Research Group, IDDRG 2015, Shanghai, Juni 2015, S. 674-687 |

| [9] | Nestler, M.; Hensel, S.; Drossel, W.-G.; Müller, R.: Requirements for a process chain for manufacturing of piezoceramic-aluminum sandwiches. Materials Science Forum, No. 825-826, S. 377–384, 2015 (DOI: 10.4028/www.scientific.net/MSF.825-826.377) |

| [10] | Drossel, W.-G.; Müller, R.; Ihlemann, J.; Rudolph, M.; Hensel, S.; Nestler, M.: Local pre-curing of an adhesive for the fabrication of shaped piezo-metal-compounds; 5. Wissenschaftliches Symposium PT-Piesa, September 2015, S.41-46 |

| [11] | Drossel, W.-G.; Schubert, A.; Koriath, H.-J.; Wittstock, V.; Peter, S.; Müller, R.; Müller, M.; Hensel, S.; Nestler, M.; Jahn, S. F.; Pierer, A.; Müller, B.; Schmidt, M.: Experimental and numerical study on the electro-mechanical behavior of piezoceramic fibers during joining by forming; 5. Wissenschaftliches Symposium PT-Piesa, September 2015, S. 71-76 |

Contact

Project Manager:Prof. Dr.-Ing. Welf-Guntram Drossel

Fraunhofer-Institut für Werkzeugmaschinen und Umformtechnik IWU

Reichenhainer Straße 88

09126 Chemnitz

E-Mail: welf-guntram.drossel@…

Dr.-Ing. Roland Müller

Fraunhofer-Institut für Werkzeugmaschinen und Umformtechnik IWU

Reichenhainer Straße 88

09126 Chemnitz

E-Mail: roland.mueller@…