Detection of local icing on wing panels by piezo modules - Demonstrator assembly with optional de-icing

Aims

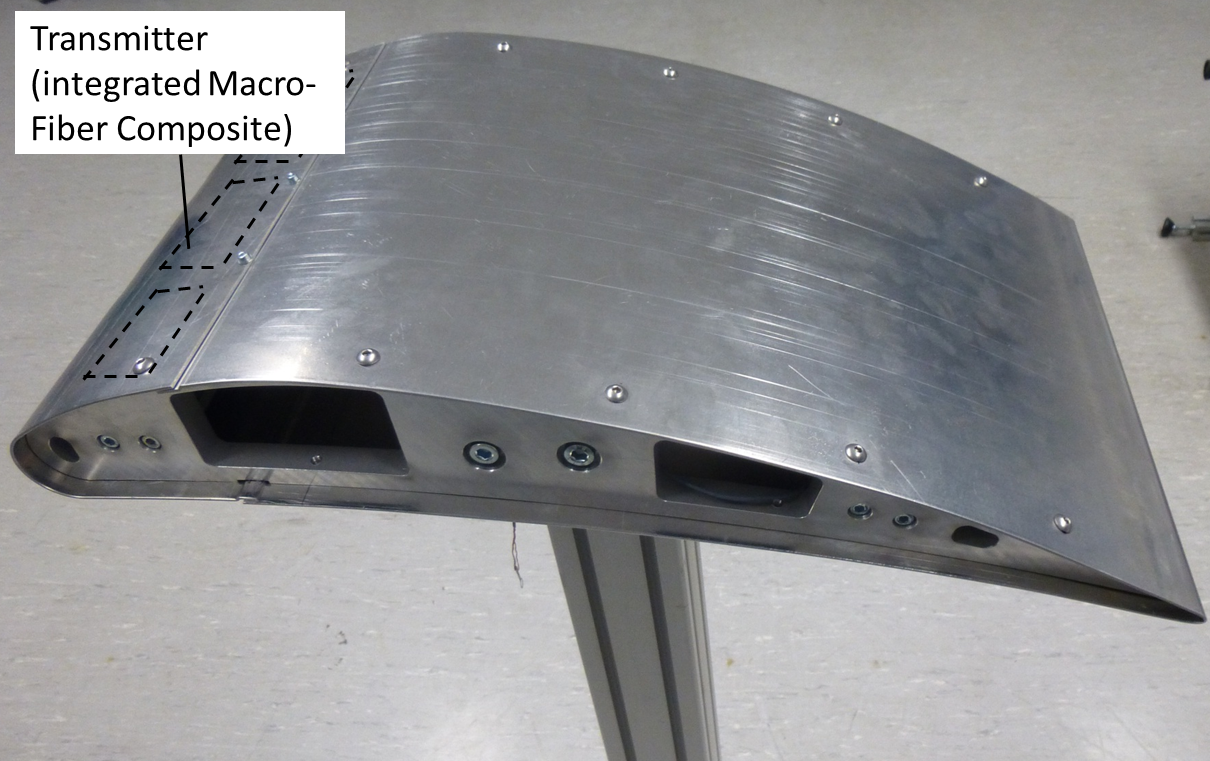

The aim is the detection of local icing on wing panels by means of integrated sensor and actuator technology (cf. Figure 1). Furthermore is analyzed, how integrated piezo modules can be used to de-ice or sustain the de-icing process (in combination with heating units) and how they can be used to avoid the icing process. The studies have been performed on a demonstrator assembly, which is designed as a cutout of a wing panel (cf. Figure 2).

Figure 1: Iced wing panel of a small aircraft [DWD17]

Figure 2: Demonstrator „aircraft wing panel“ with integrated piezo modules

Results

Preliminary investigation

To verify the feasibility of icing detection by integrated piezo elements, pretests were performed on demonstrator structure „aircraft wing panel“. The frequency response analysis of the integrated piezo module at different temperatures (i. e. room temperature, -40 °C) and the impact of additional mass (i. e. ice) served to identify the respective resonance frequencies. To investigate the influence of additive mass and temperature on the resonance frequency, impedance and angle of loss were measured by various excitation frequencies. The frequency response analysis of piezo modules was performed by room temperature and without additive mass (cf. Figure 3). Additional frequency response analysis was performed by tempered demonstrator structure at -40 °C with and without additional mass.

Room temperature (initial state)

Room temperature, with additive mass

-40 °C, without additive mass

-40 °C, iced (with additive mass)

Figure 3: Detection of icing impact on resonance frequencies of demonstrator structures „aircraft wing panel“

The results show that mass increase at room temperature and down to temperatures of -40 °C can be detected by means of integrated piezo elements.

Methods

The approach includes the definition of natural frequencies and natural modes with local maxima of shifts, which are appropriate for a detection of icing and de-icing processes. The targeted positioning of piezo elements allows stimulating selected frequencies, while shifts of resonance frequencies are induced by mass increase of local icing. The resonance frequencies are detected by integrated piezo modules. Vibrations were initiated for a mechanical de-icing process or to sustain the de-icing process with thermal heating elements. Used piezo modules were developed in SFB/TR39 with the special compatibility to thermoplastic bonding (TPM) (cf. TP A05) and integrated in TP B01 developing demonstrator „aircraft wing panel“ consisting of aluminum sheet. Key work tasks are:

- Concept development for structural integration of multiple piezo modules in demonstrator structure and their sensor and actuator usage

- FE-Simulation of suitable positions for sensor and actuator

- Manufacturing of demonstrator structure by forming technologies

- Functional characterization of demonstrator, i. e. detection of natural frequencies and vibration forms by vibrometer measurements

- Functional test of icing detection, i. e. targeted stimulation of resonance frequencies and detection of response signal by local icing

- Concept development and functional test for de-icing process sustained by vibration and avoidance of icing

Source

[DWD17] Deutscher Wetterdienst: Erkennung vereisungsgefährdeter Lufträume (ADWICE), https://www.dwd.de/DE/forschung/wettervorhersage/met_fachverfahren/unterstuetzung_flugwettervorhersage/adwice.html, 2017

Contact

Dr.-Ing. Matthias Nestler

Fraunhofer Institute for Machine Tools and Forming Technology

Reichenhainer Straße 88, 09126 Chemnitz

Phone: 0371 5397 1263

E-Mail: matthias.nestler@…

Dr.-Ing. Thomas Mäder

Fraunhofer Institute for Machine Tools and Forming Technology

Reichenhainer Straße 88, 09126 Chemnitz

Phone: 0371 5397 1577

E-Mail: thomas.maeder@…

Dr.-Ing. Burkhard Kranz

Fraunhofer Institute for Machine Tools and Forming Technology

Nöthnitzer Straße 44, 01187 Dresden

Phone: 0371 4772 2341

E-Mail: burkhard.kranz@…