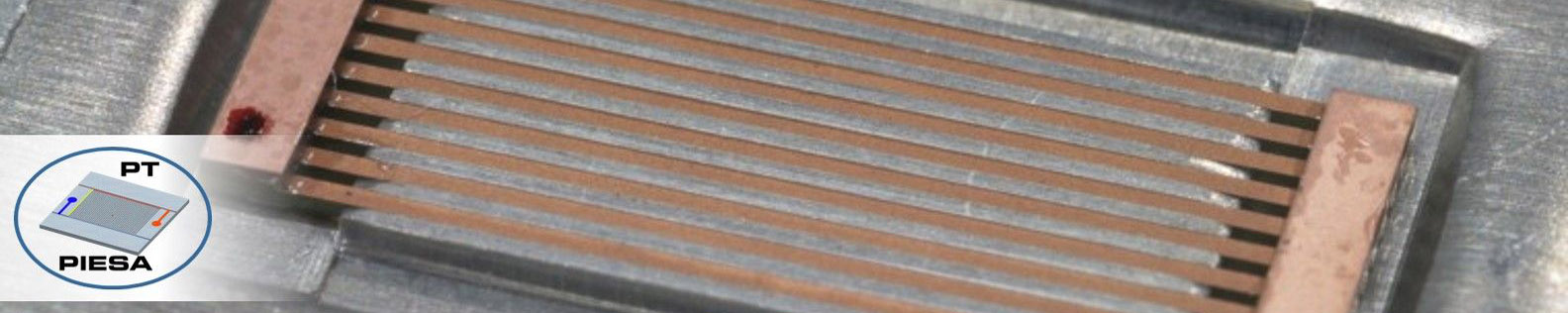

Model-based ultrasound imaging for spatially resolved flaw detection in layered composites

S. J. Rupitsch

Aims

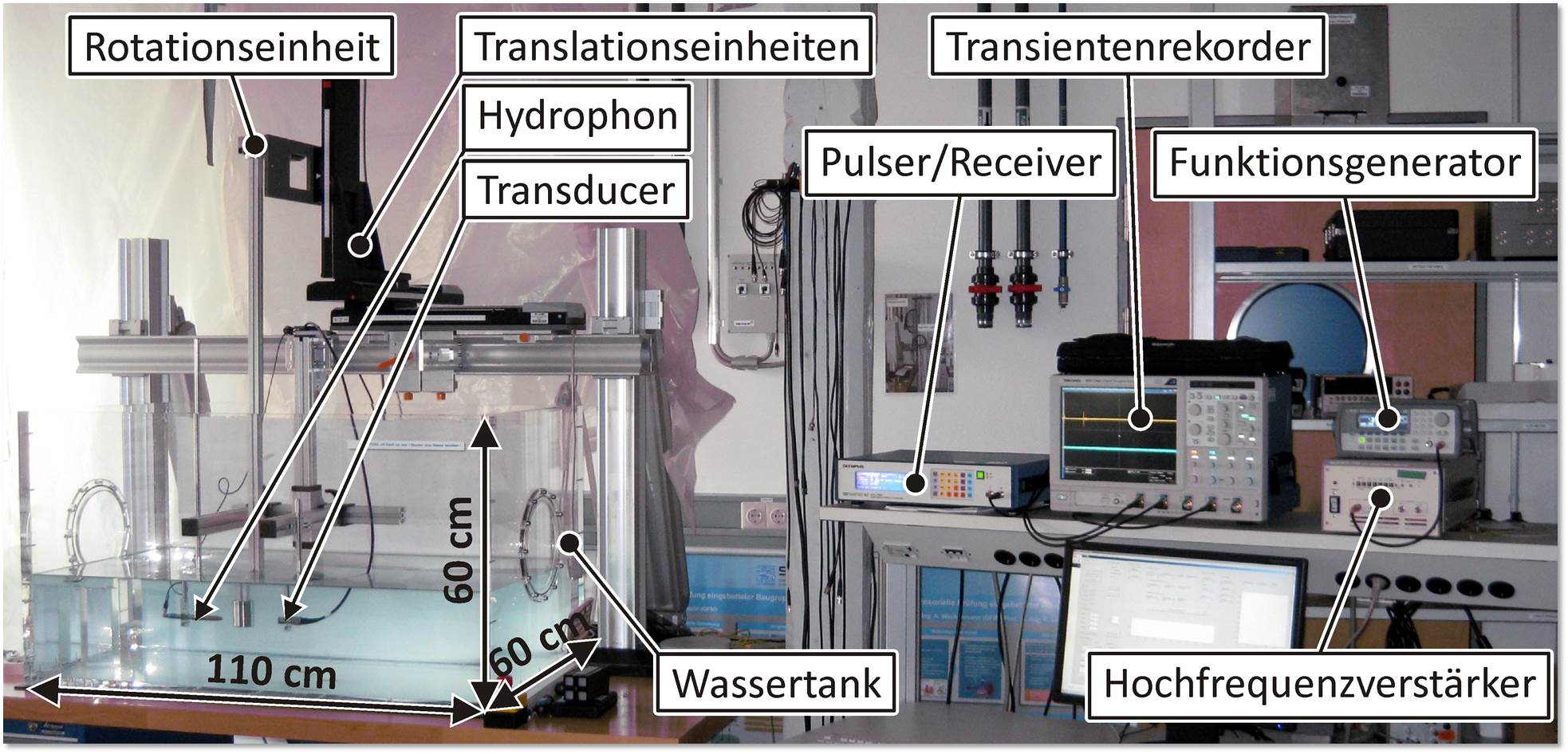

Constructing and realizing a specific acoustic microscope

|

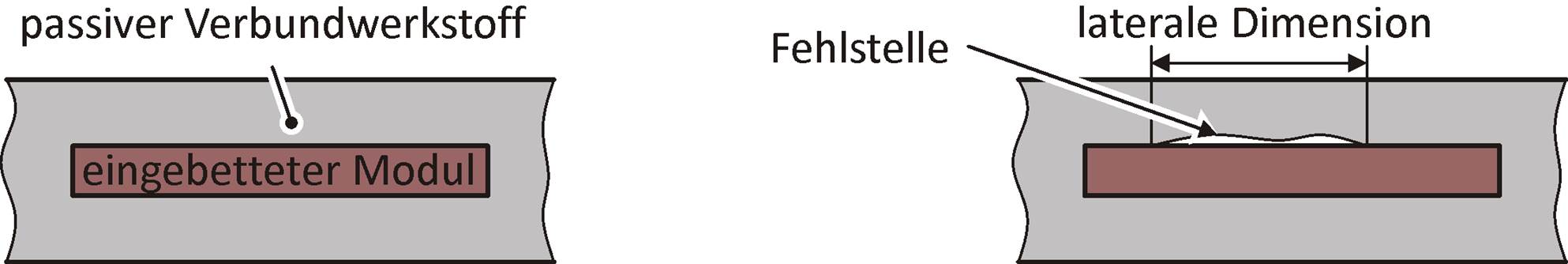

- Spatially resolved flaw detection between the embedded piezoceramic module and the surrounding composite material

- Uncertainty of measurement in lateral direction < 100 µm

Guidelines for applying synthetic focusing techniques

- Optimized lateral spatial resolution

- Shortened measurement time and postprocessing

Evaluating flaws regarding the layered composites’ functionality

- Qualitative and quantitative evaluation

- Appearance and Changing of flaws under continuous operating conditions

Methods

| Efficient simulation by SIR/FE method |

|---|

|

| Ultrasound-based inspection | |

|---|---|

|

|

Publications

Reviewed Publications

| [Wue17] | Wüst M, Eisenhart J, Rief A, Rupitsch SJ (2017) System for acoustic microscopy measurements of curved structures, In: Technisches Messen. doi: 10.1515/teme-2016-0085 |

| [Schr13] | Schrapp M, Scharrer T, Goldammer M, Rupitsch SJ, Sutor A, Ermert H, Lerch R (2013) Artifact reduction in nondestructive testing by means of complementary data fusion of X-ray computed tomography and ultrasonic pulse echo testing. Meas Sci Technol 24:1-11 |

| [Rup07a] | Rupitsch SJ, Zagar BG (2007) Acoustic microscopy technique to precisely locate layer delamination. IEEE Trans Instrum Meas 56(4):1429-1434 |

| [Rup07b] | Rupitsch SJ, Kindermann S, Zagar BG (2007) Solution of a non-linear inverse problem to identify the surface normal velocity of ultrasound transducers. Elektrotechn Informationstechn 124(7-8):260-265 |

| [Rup08a] | Rupitsch SJ, Kindermann S, Zagar BG (2008) Estimation of the surface normal velocity of high frequency ultrasound transducers. IEEE Trans Ultrason Ferroelectr Freq Control 55(1):225-235 |

| [Rup08b] | Rupitsch SJ, Zagar BG (2008) Verfahren zur Erhöhung der örtlichen Auflösung bei synthetisch fokussierten Ultraschalltransducern. Techn Messen 75(4):259-267 |

| [Rup08c] | Rupitsch SJ (2008) Entwicklung eines hochauflösenden Ultraschall-Mikroskops für den Einsatz in der Zerstörungsfreien Werkstoffprüfung. Dissertation Johannes-Kepler-Universität Linz |

Other publications

| [Wue16] | Wüst M, Nierla M, Rupitsch SJ (2016) A Model-Based Synthetic Aperture Focusing Technique for Acoustic Microscopy, In: IEEE IUS. Tours, France, 2016. |

| [Wue15a] | Wüst M, Nierla M, Rupitsch SJ (2015) Modellgestützte Ultraschallmikroskopie zur dimensionellen Erfassung von Fehlstellen in Festkörpern. In: DAGA 2015. Nuremberg, Germany 2015. |

| [Wue15b] | Wüst M, Nierla M, Rupitsch SJ (2015) Towards a model-based high-resolution ultrasonic measurement system for non-destructive testing. In: CRC/TR 39 - 5th Scientific Symposium Proceedings. Dresden, Germany 2015. |

| [Scha12] | Scharrer T, Koch A, Fendt KT, Rupitsch SJ, Sutor A, Ermert H, Lerch R (2012) Ultrasonic defect detection in multi-material axis-symmetric devices with an improved synthetic aperture focusing technique. In: IEEE IUS. Dresden, Germany, pp 1039-1042 |

| [Scha13] | Scharrer T, Koch A, Rupitsch SJ, Sutor A, Ermert H, Lerch R (2013) Ultrasonic imaging of a turbine blade model using 360° synthetic-aperture-focusing-technique and reverberation suppression. In: IEEE IUS. Prague, Czech Republic, pp 150-153 |

Contact

Project Manager:Dr. techn. Stefan Johann Rupitsch

Friedrich-Alexander-Universität Erlangen-Nürnberg

Lehrstuhl für Sensorik

Paul-Gordan-Str. 3/5

91052 Erlangen

E-Mail: stefan.rupitsch@…