Integration of piezoceramic modules in aluminium castings using high pressure die casting – Technology development and numerical process simulation

C. Körner

Aims

The subproject B03 is developing large-scale production applicable technologies for the integration of piezoceramic actor-sensor modules into aluminium high pressure die castings. Essential parts of the research include:

- Development of a large scale applicable production/casting technology

- Optimal positioning and efficiency of the integrated sensor-actor modules

- High pressure compound casting (HPCC) using ultrathin Zn-layers for enhanced mechanical properties

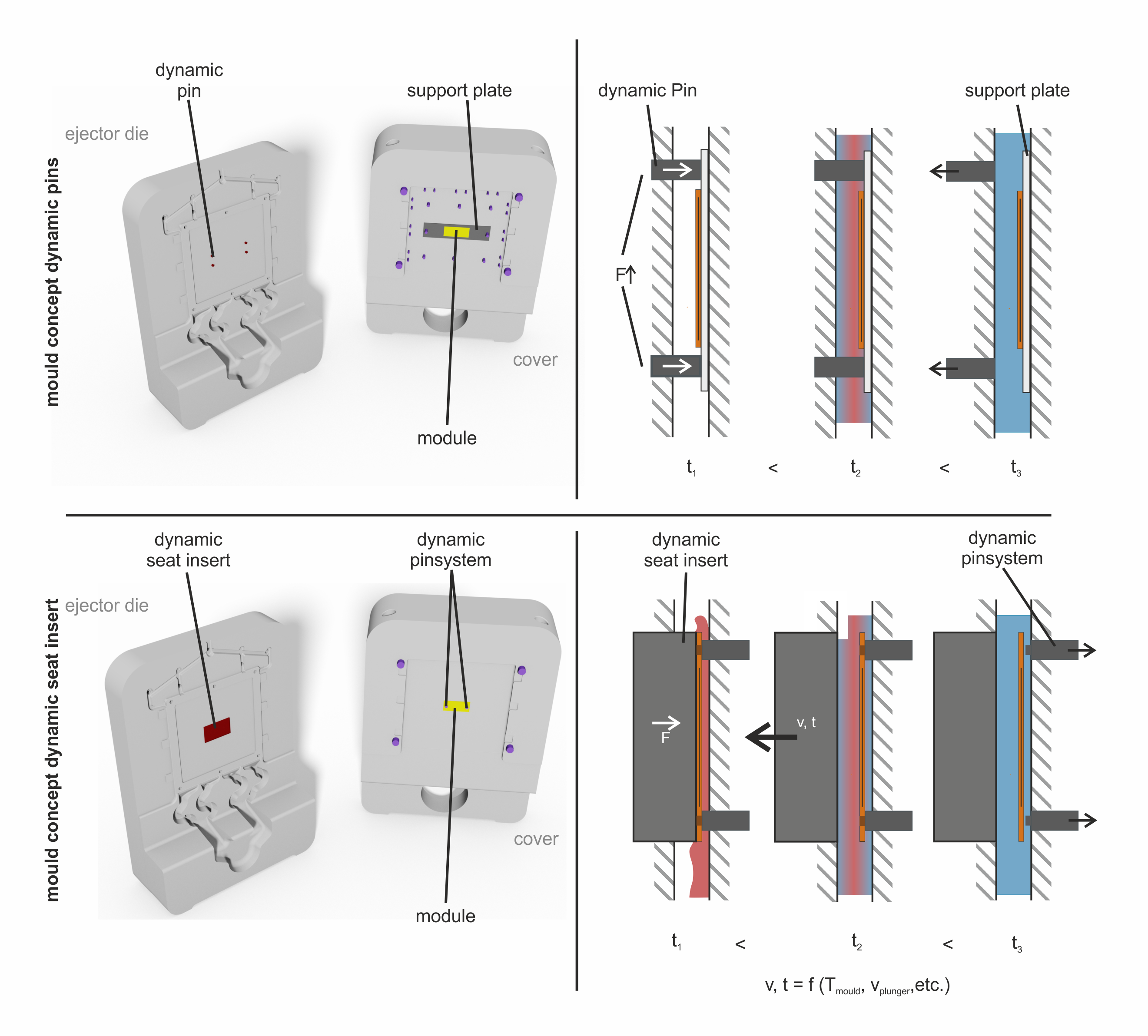

- Dynamic fixing system for minimal insert volume

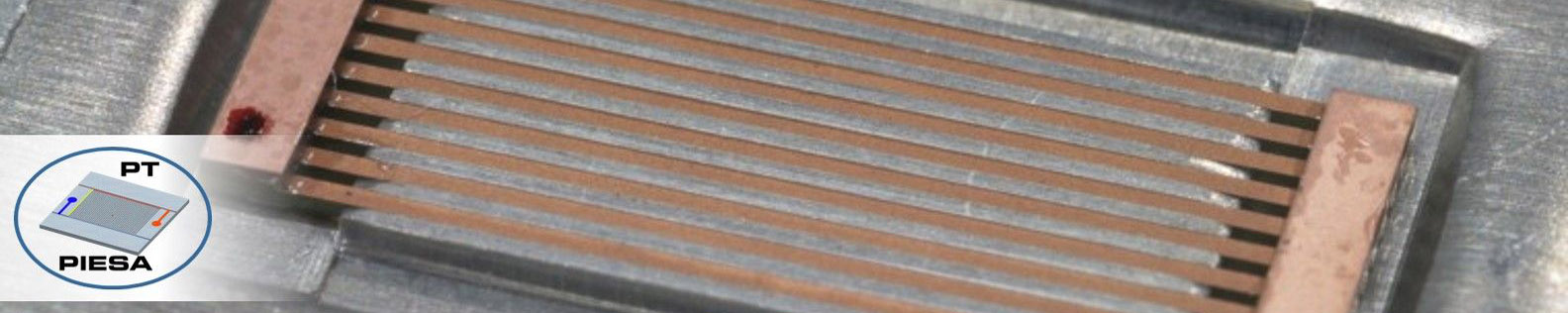

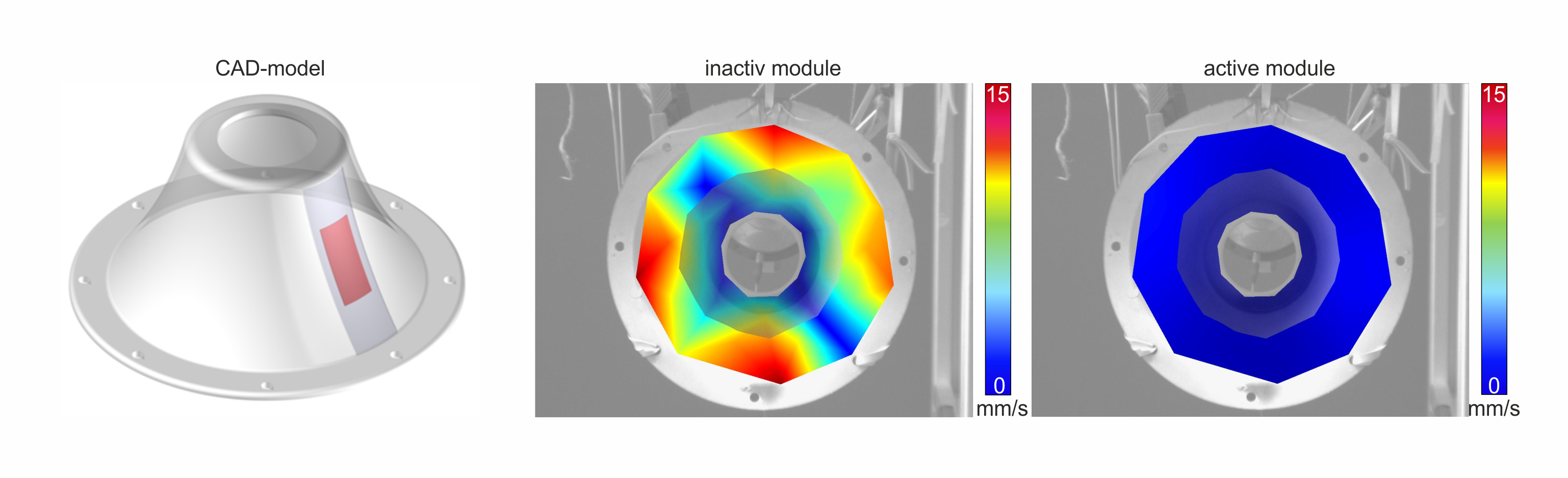

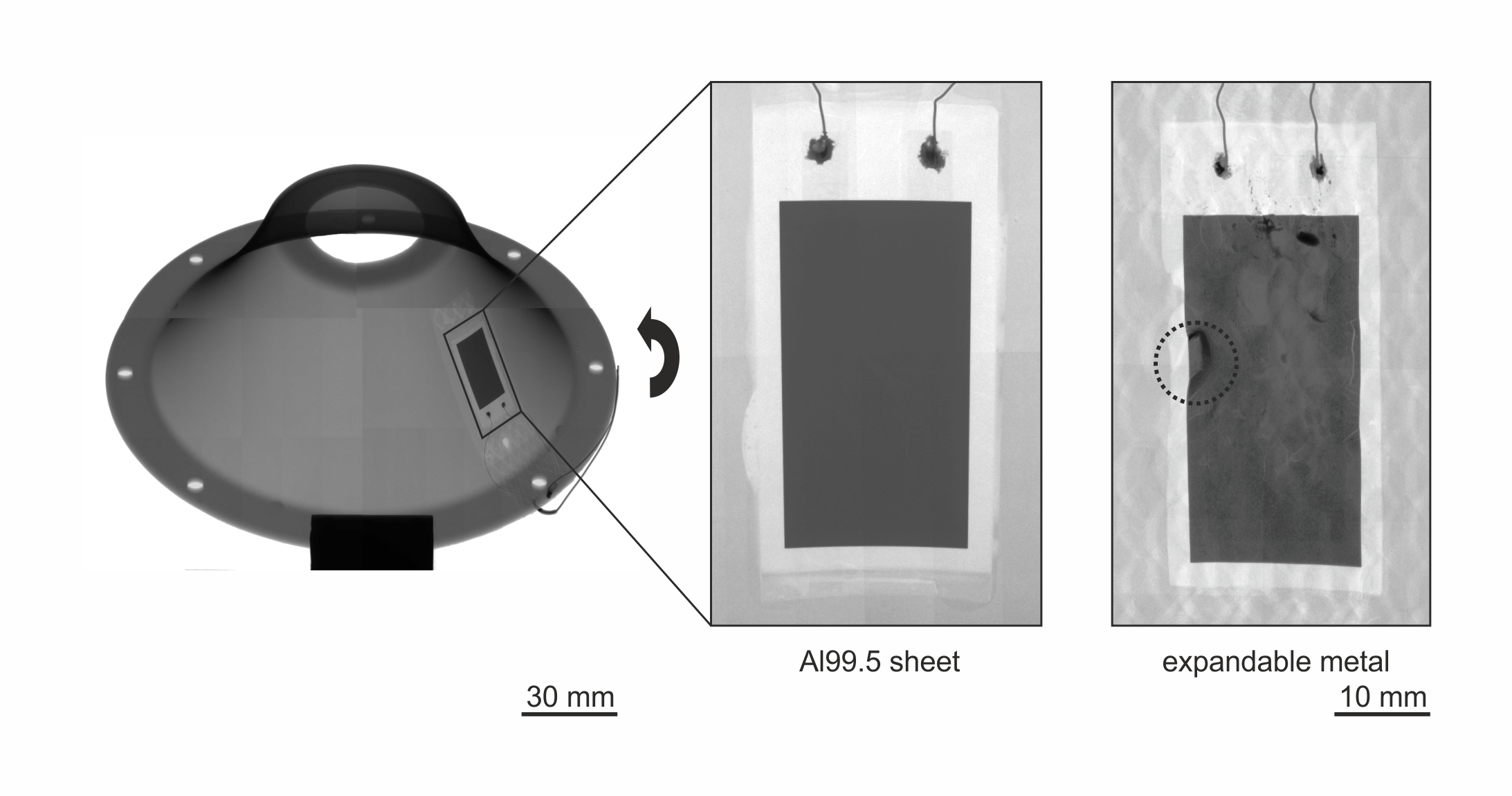

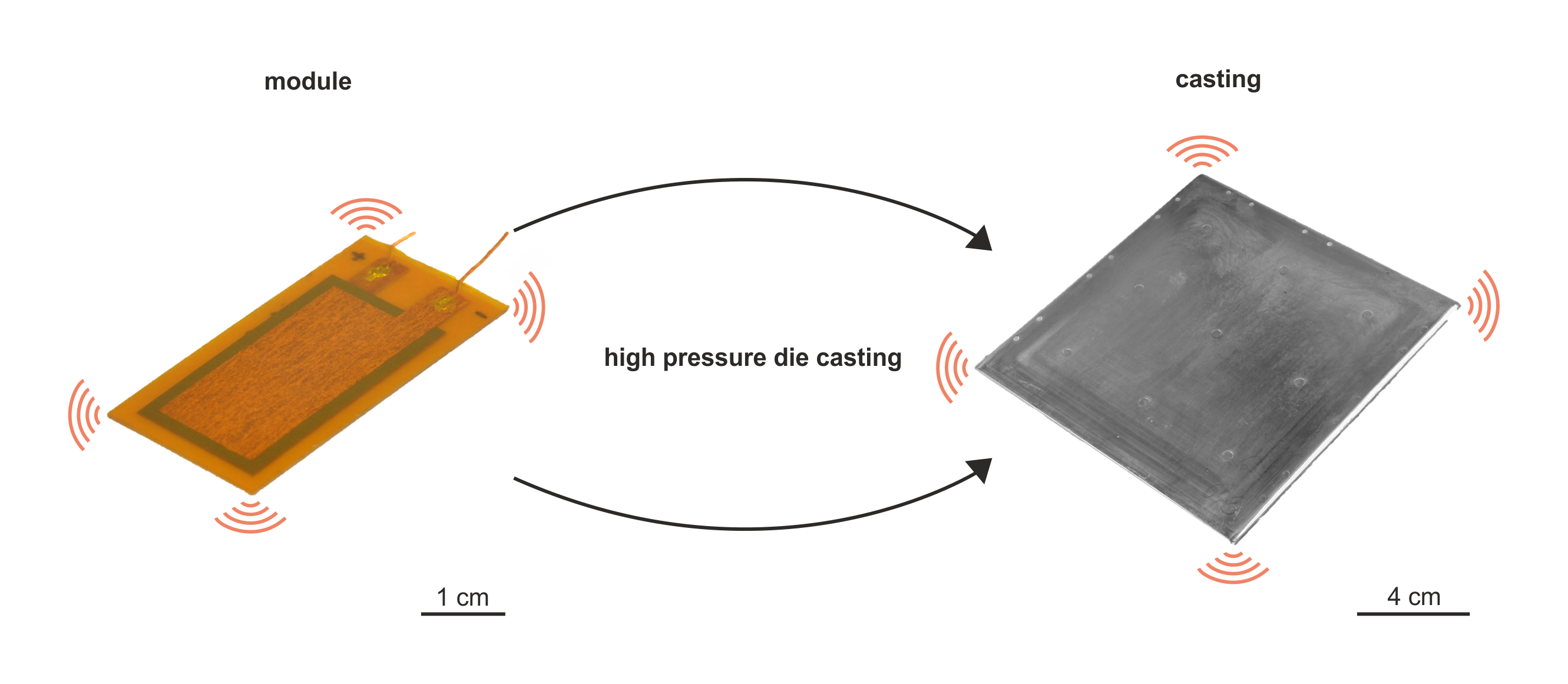

Fig. 1: Illustration of piezoceramic module and active casting.

Results

Challenges within the process

|

|

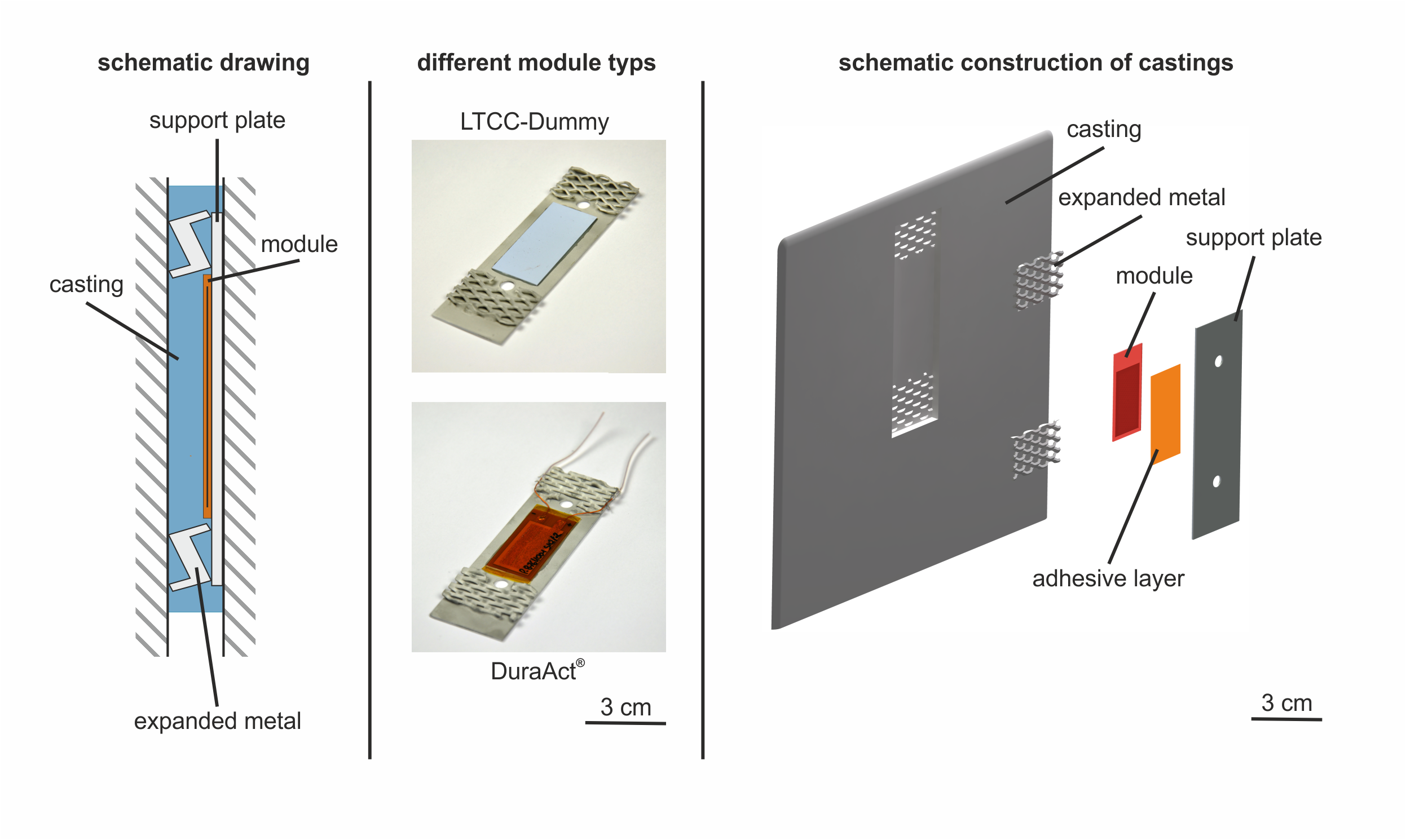

Hybrid fixing system

Fig. 2: Details for hybrid fixing system: Theoretical design – module variation – components within the active casting. |

|

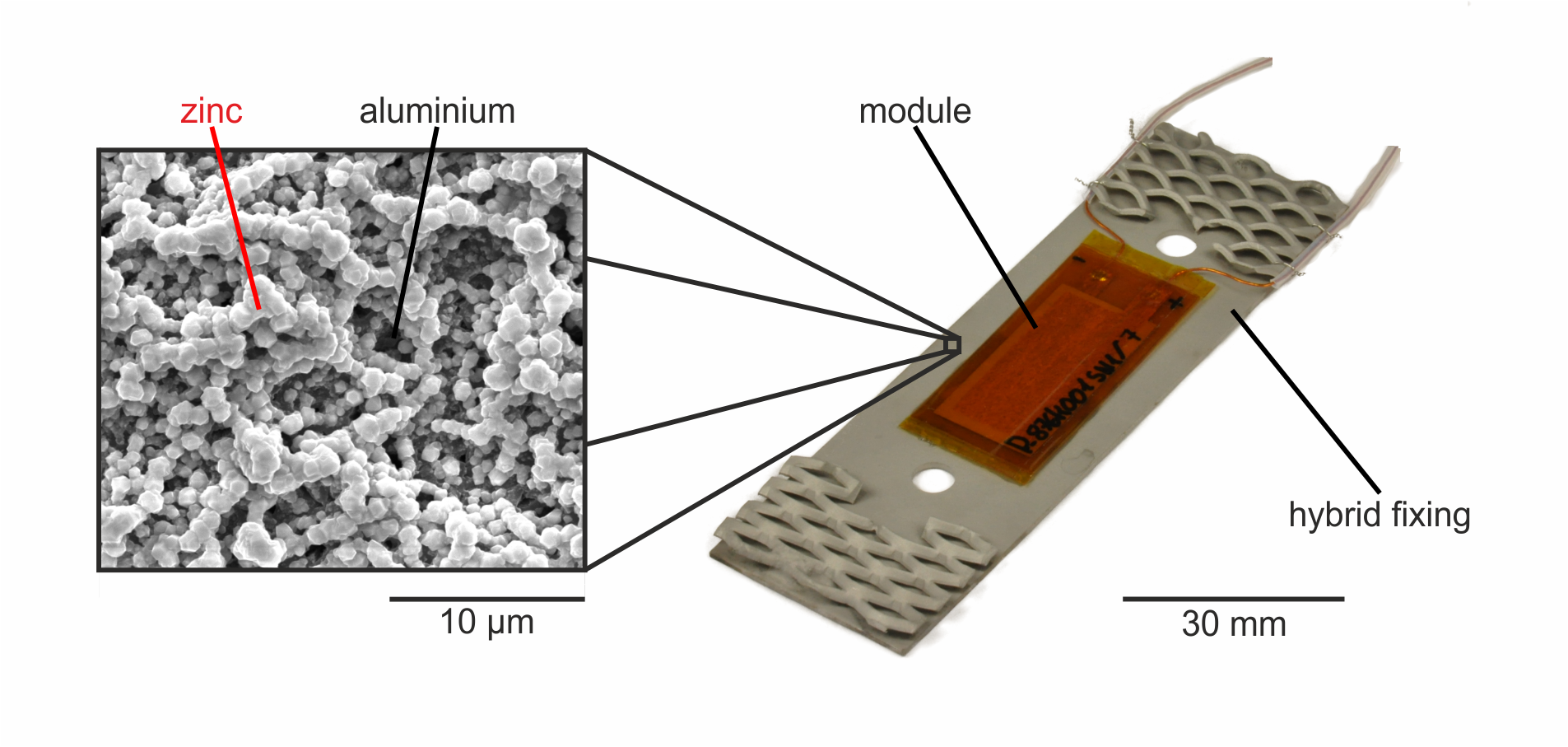

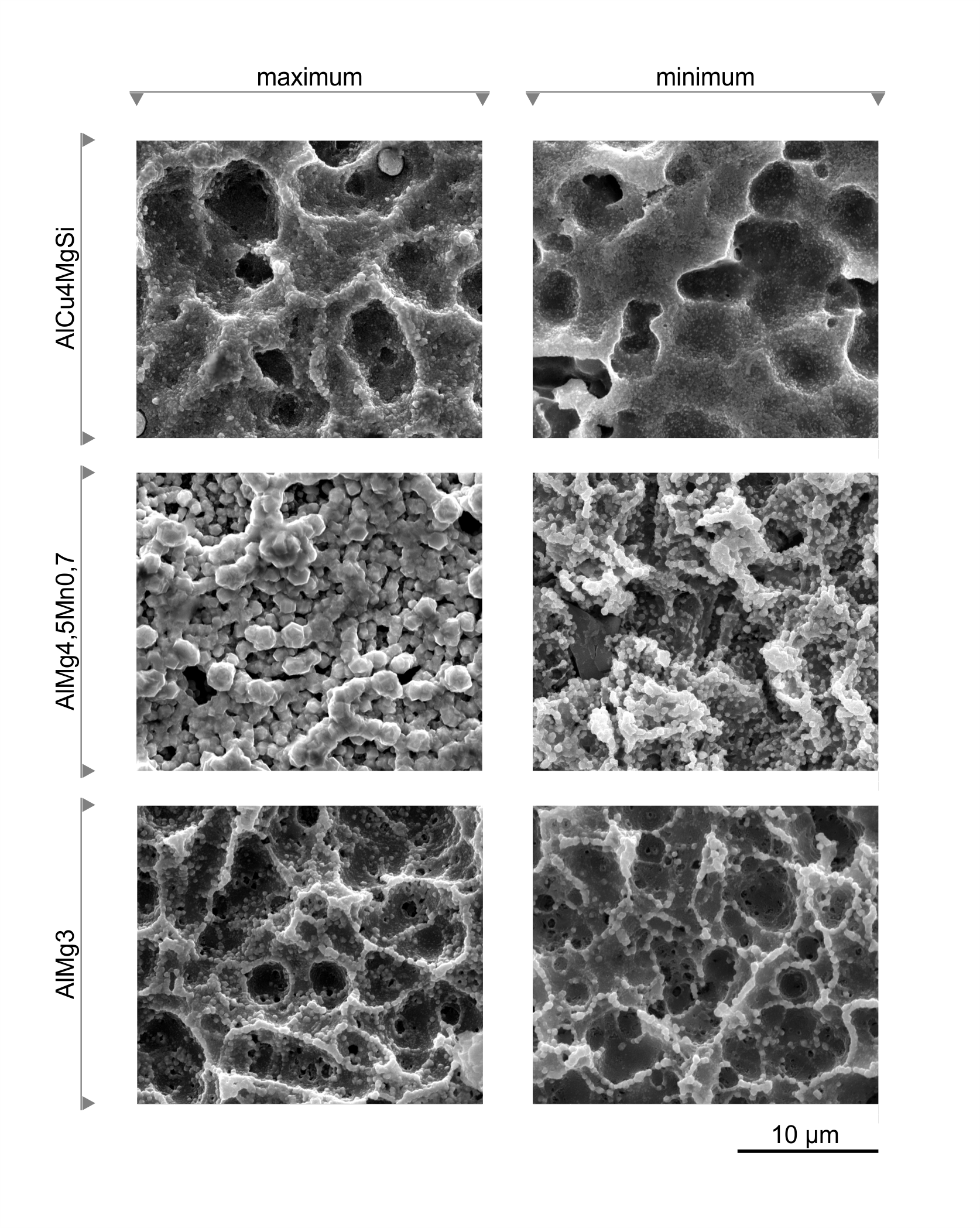

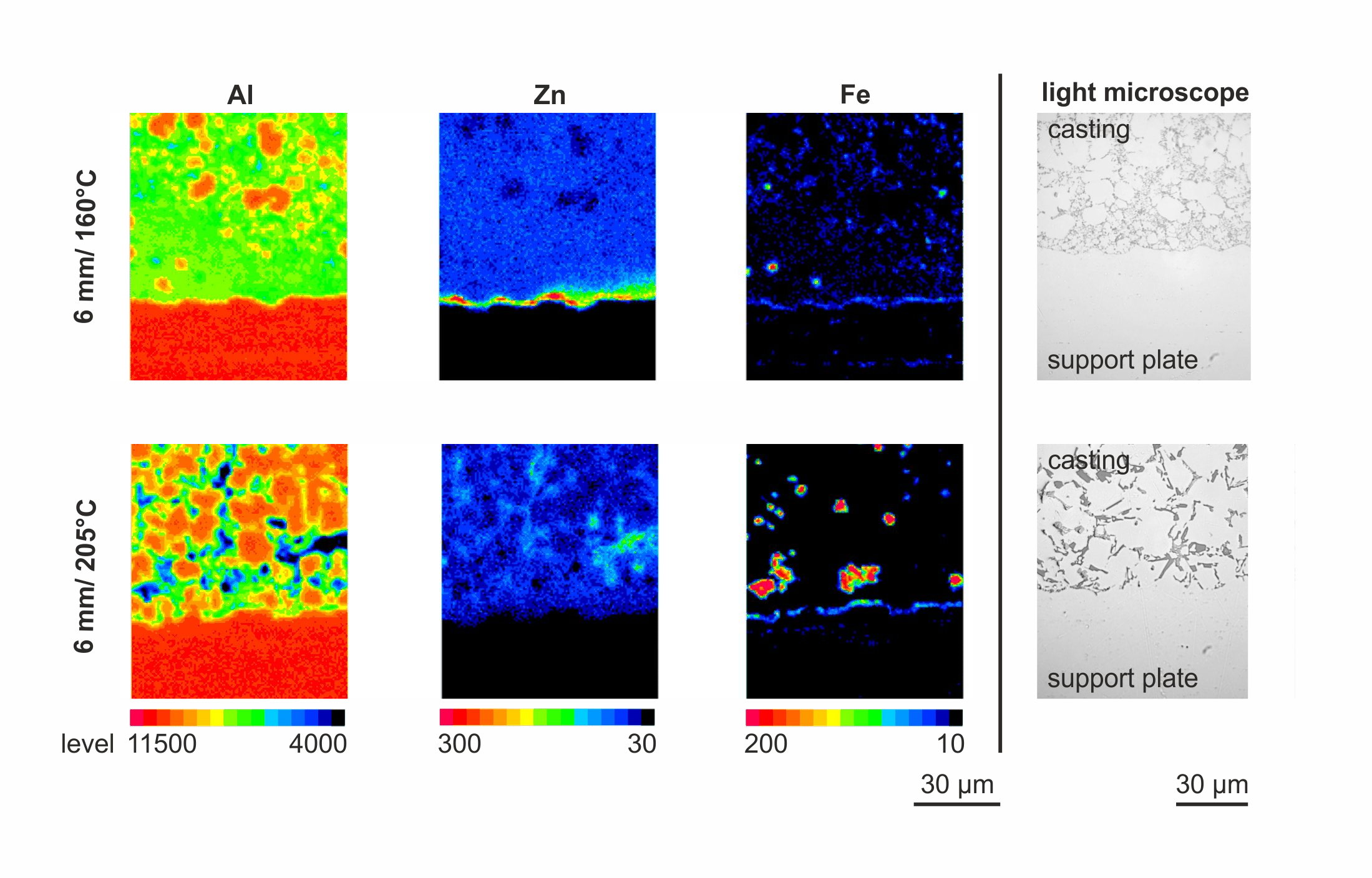

Functional Zn-compound layer

Fig. 3: Finished casting in the precast condition including an ultrathin zinc layer coated via zincate treatment.

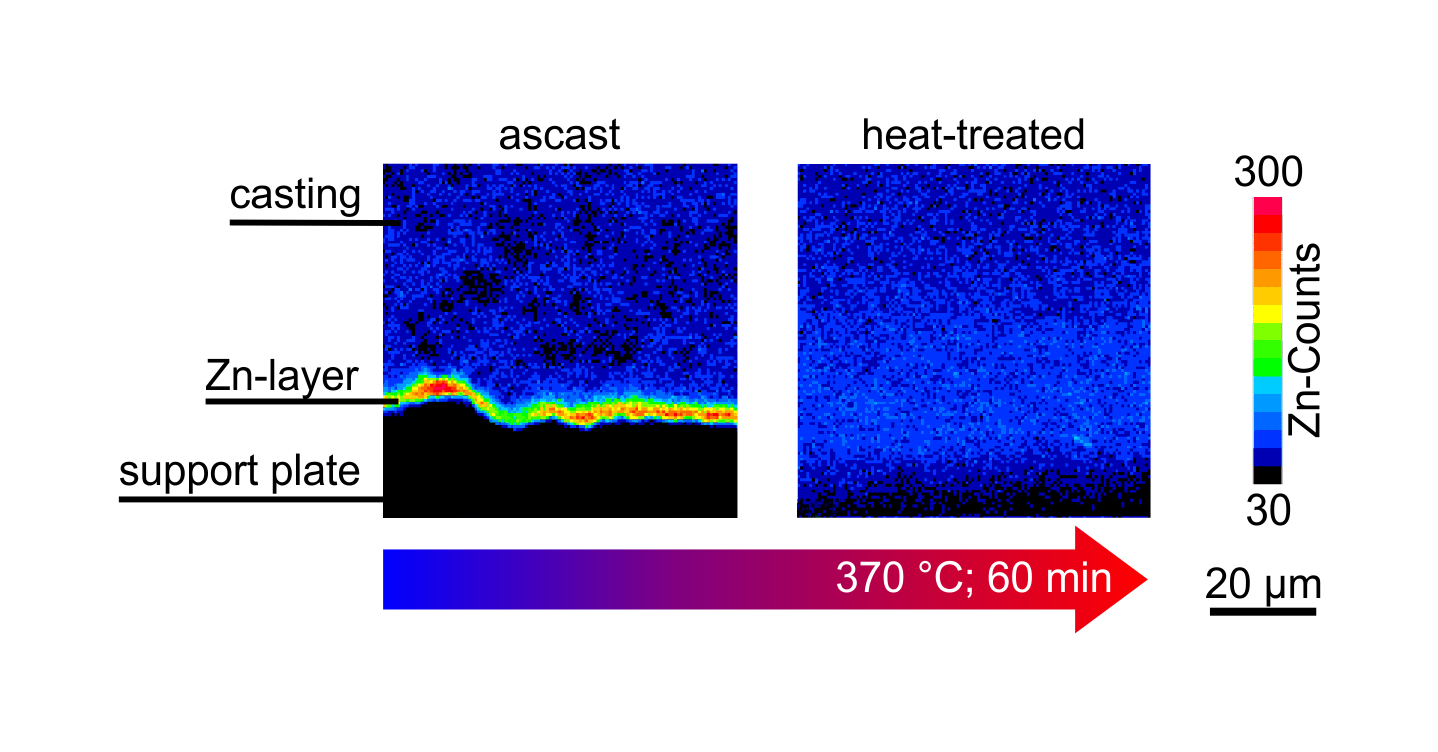

Fig. 4: Microprobe image of Al-Al-compound segment in the ascast and heat-treated condition. |

|

Integration behaviour

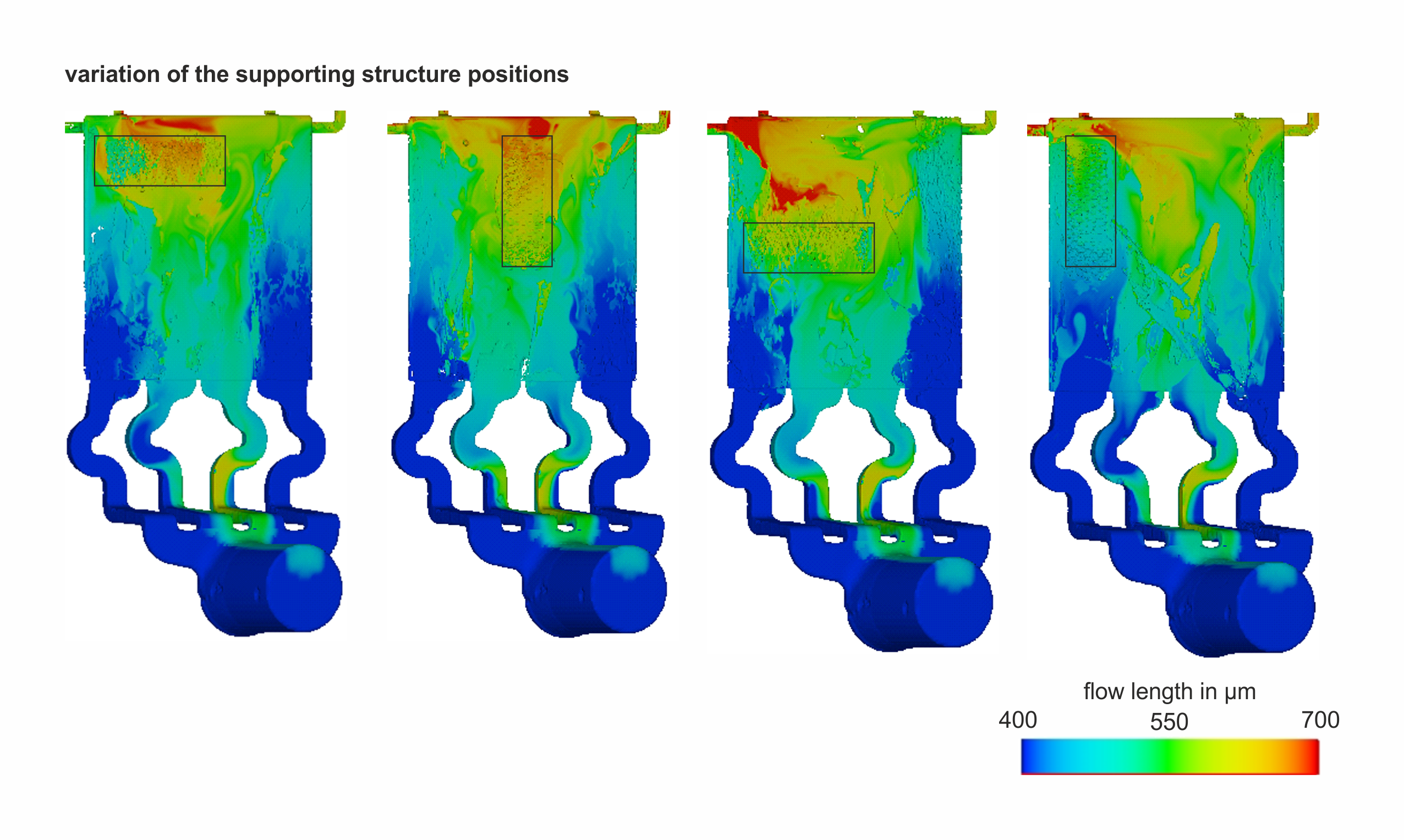

Fig. 5: Simulation results of the integration behaviour with different positions of the insert. |

|

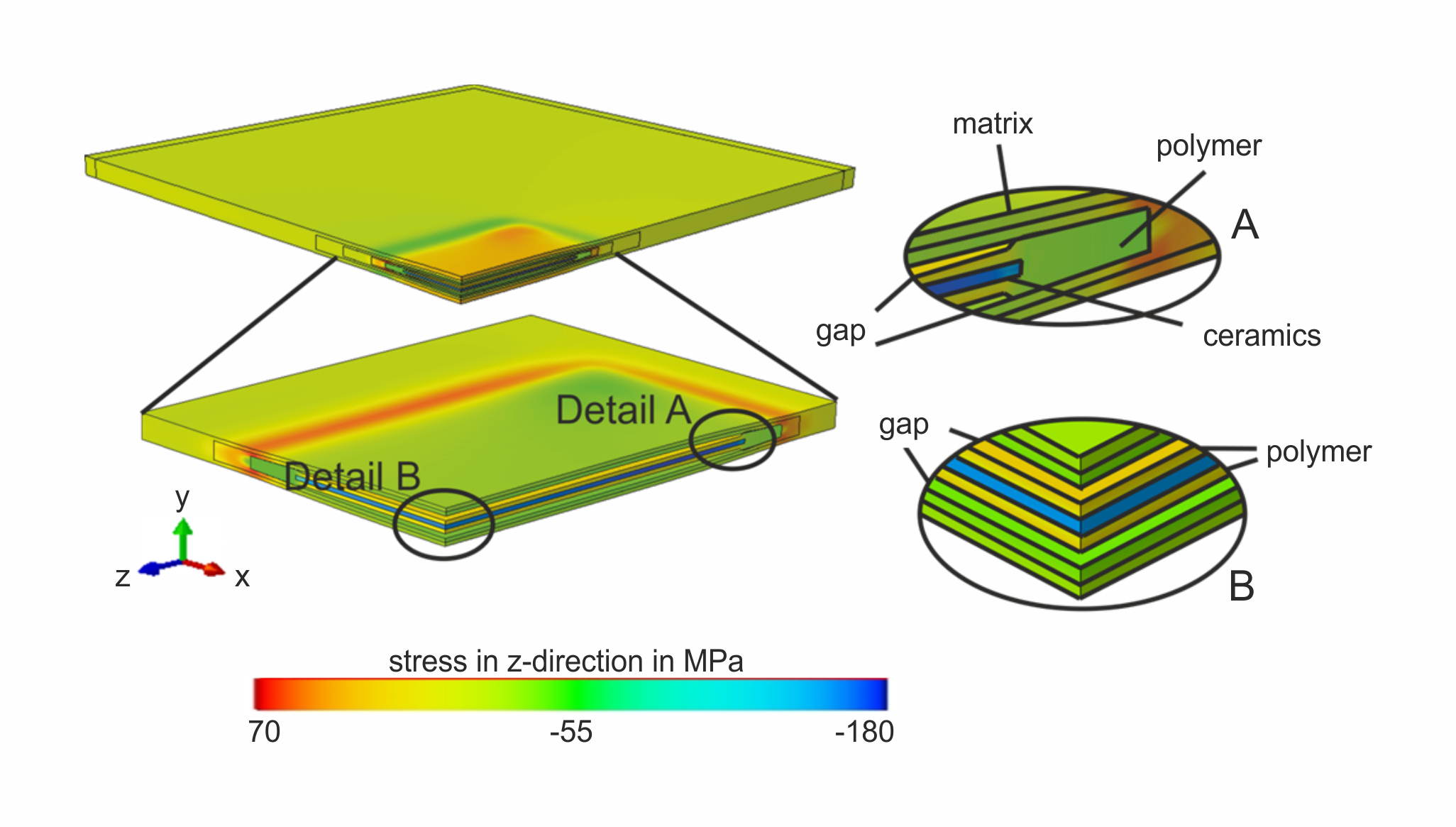

Residual stresses and thermal distortion

Fig. 6: Numerical 3D-calculation of the residual stresses based on casting parameters. |

|

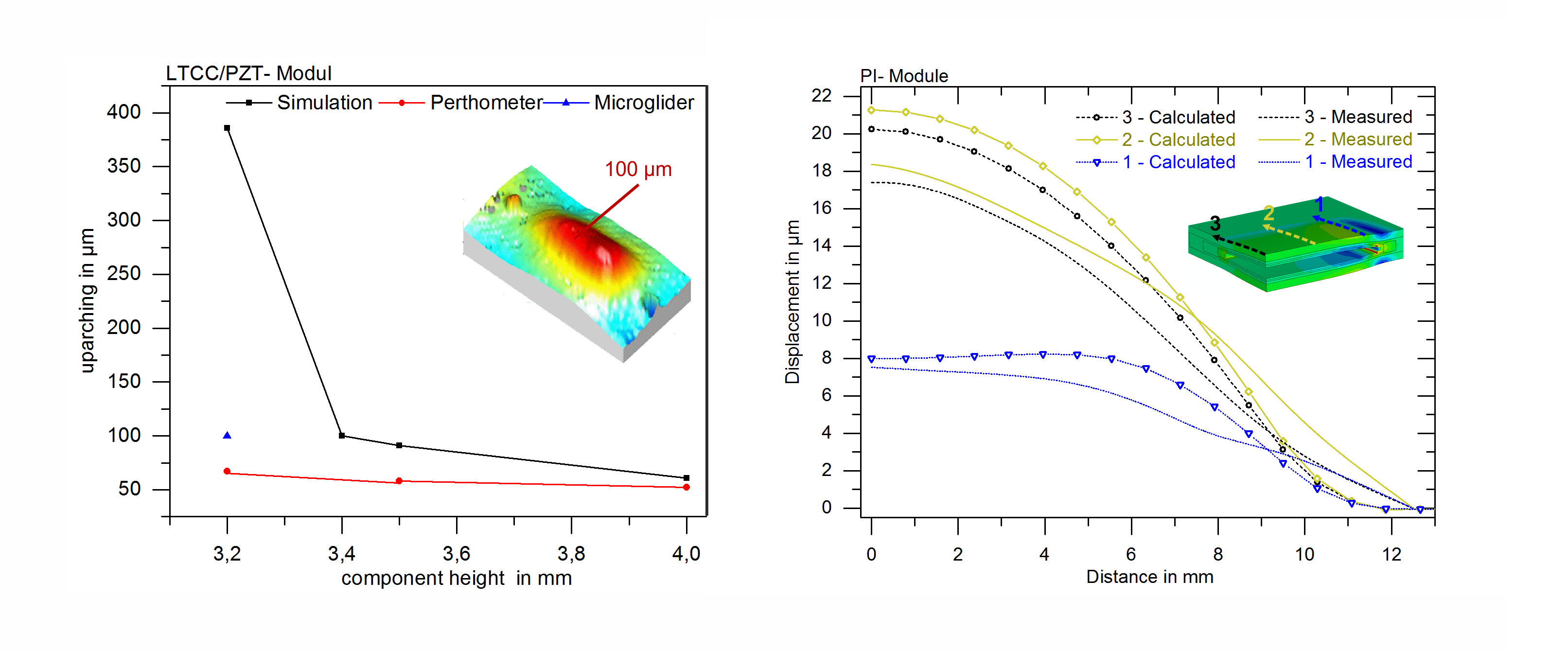

Verification of thermaly induced distortion

Fig. 7: Verification of thermally induced distortion: (left) for LTCC/PZT Modules. (right) PI-Modules |

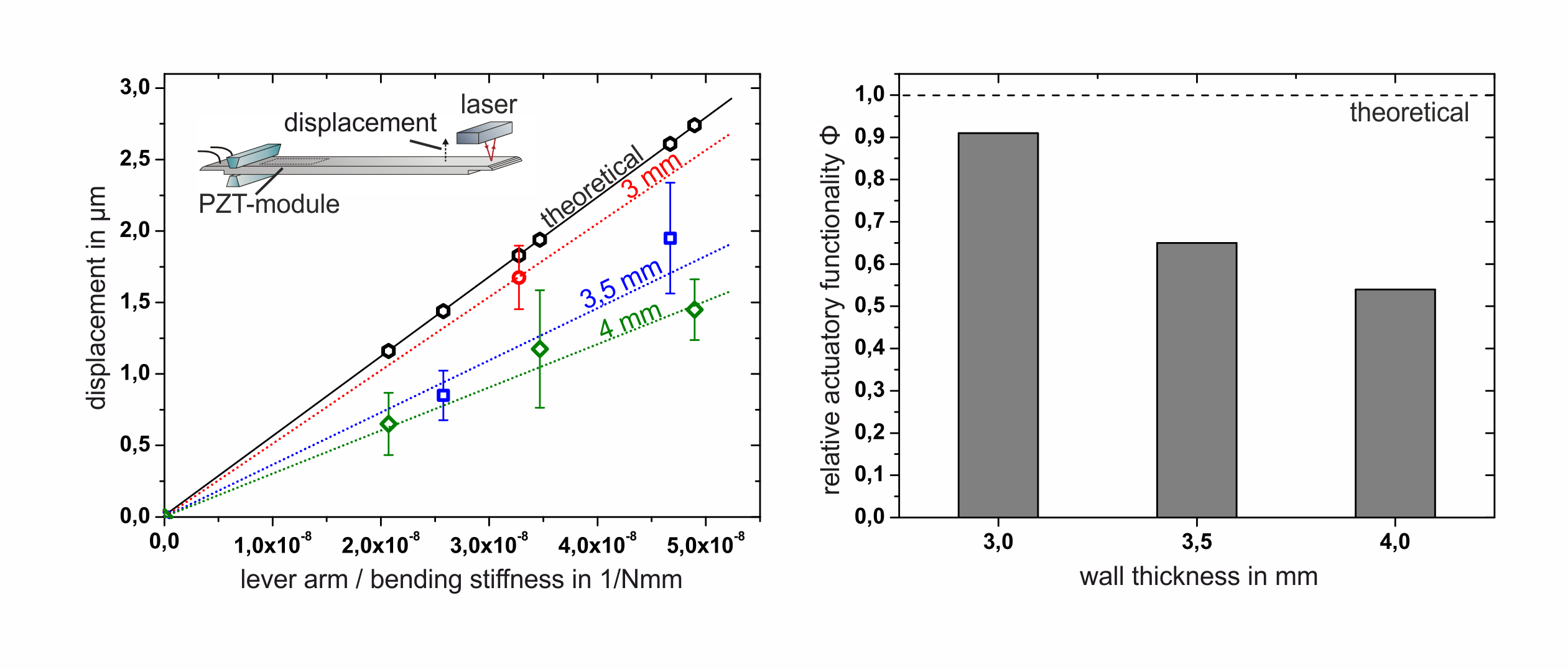

Functionality

Fig. 8: Actuatoric behaviour of the active castings using displacement measurements. Enhanced functionality is observed for thinner castings and higher eccentric position of the piezoceramic module. |

|

Demonstrator

Fig. 9: Theoretical setup and active damping measurements for the first natural frequency (≈ 980 Hz) of the demonstrator casting “bell”. |

Methods

| Process development | |

|---|---|

Fig. 10: Schematic design (left) and concept (right) for dynamic fixing systems. Top: dynamic pins with substitute expandable metal parts. Bottom: Dynamic tool parts stabilize the module during casting – in-situ generated support structure. |

| Coating technology | |

|---|---|

Fig. 11: Parametric study for zincate coating and different sheet alloys. |

| Characterisation | |

|---|---|

Fig. 12: Microprobe and light microscope images of Al-Al-compound casting.

Fig. 13: x-ray images of demonstrator casting “bell”. |

Publications

Reviewed Publications

| [Kla12] | Klassen A, Rübner M, Ilg J, Rupitsch SJ, Lerch R, Singer RF, Körner C (2012) Influence of the fabrication process on the functionality of piezoceramic patch transducers embedded in aluminum die castings. Smart Mater Struct 21:115014(11pp) |

| [Köp14] | Köpf J, Rübner M, Klassen A, Singer RF, Körner C (2014) Thermo-mechanical loads on piezoceramic modules integrated in high pressure die castings. Int Foundry Res 2014(1) |

| [Rüb11a] | Rübner M, Günzl M, Körner C, Singer RF (2011) Aluminium-aluminium compound fabrication by high pressure die casting. Mater Sci Eng A 528(22-23):7024-7029 |

| [Sch13a] | Schwankl M, Kellner R, Singer RF, Körner C (2013) The influence of sandblasting on the morphology of electroless deposited zinclayers on aluminum sheets. Appl Surf Sci 283:202-208 |

| [Sch13b] | Schwankl M, Rübner M, Singer RF, Körner C (2013) Integration of PZT-Ceramic Modules using Hybrid Structures in High Pressure Die Casting. Proc Mater Sci 2:166-172 |

| [Suc12] | Suchaneck G, Eydam A, Rübner R, Schwankl M, Gerlach G (2012) A Simple Thermal Wave Method for the Evaluation of the Polarization State of Embedded Piezoceramics. Ceram Int 39(1):S587-S590 |

| [Sch13c] | Schwankl M, Rübner M, Flössel M, Gebhardt S, Michaelis A, Singer R F, Körner C (2013) Active functionality of piezoceramic modules integrated in aluminum high pressure die castings. Sens Actuators A, doi:10.1016/j.sna.2013.12.016 |

| [Kör14] | Körner C, Schwankl M, Himmler D (2014) Aluminum-Aluminum compound castings by electroless deposited zinc layers. Mater Process Technol, doi:10.1016/j.jmatprotec.2013.12.014 |

Other Publications

| [Kla11] | Klassen A, Rübner M, Ilg J, Rupitsch SJ, Lerch R, Körner C, Singer RF (2011) Integration of piezoceramic sensors and actuators into structural components via high pressure die casting. In: Proc CRC/Transregio 39. Chemnitz, Germany, pp 45-50 |

| [Rüb11b] | Rübner M, Klassen A, Körner C, Singer R F, Ilg J, Rupitsch S J, Lerch R (2011) Dünnwandige Aluminiumdruckgussteile mit integrierten piezokeramischen Sensoren und Aktoren - Fertigung und Charakterisierung. In: 18. Symp Verbundwerkst Werkstoffverb, Chemnitz, S 277-282 |

| [Rüb13] | Rübner M (2013) Verfahrenstechnische und werkstoffkundliche Grundlagen zur vollständigen Integration aktiver Komponenten in Druckgussbauteile. Dissertation, FAU Erlangen-Nürnberg |

| [Sch13d] | Schwankl M, Flössel M, Köpf J, Körner C, Gebhardt S, Singer RF, Michaelis A (2013) Integration of piezoceramic components in aluminum high pressure die castings. In: Proc CRC/Transregio 39. Nuremberg, Germany, pp 33-37 |

Contact:

Project Manager:Prof. Dr.-Ing- habil. Carolin Körner

Friedrich-Alexander-Universität Erlangen-Nürnberg

Institut für Werkstoffwissenschaften

Lehrstuhl Werkstoffkunde und Technologie der Metalle

Martensstraße 5

91058 Erlangen

E-Mail: carolin.koerner@…